Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

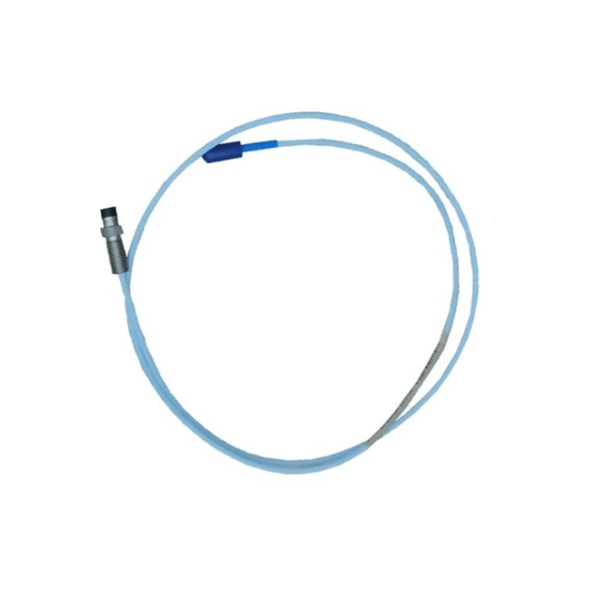

Bently Nevada 330103-01-04-10-02-05 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-01-04-10-02-05

Product Type:8 mm Proximity Probe

Origin:USA

Total Length:1.0 meter

Weight:0.323kg

Views:32

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-01-04-10-02-05 8 mm proximity probe is a highly reliable, precision measurement tool from the 3300 XL Series, designed to monitor displacement and vibration in industrial machinery. Using eddy current technology, this proximity probe can measure the relative position between a probe and a target with extreme precision, even in challenging operational environments.

The 330103-01-04-10-02-05 probe is commonly used in applications requiring high levels of accuracy in vibration monitoring, such as turbines, pumps, motors, and compressors. Its robust design and ability to operate in harsh conditions make it ideal for continuous monitoring of rotating equipment, ensuring early fault detection, minimizing downtime, and optimizing maintenance strategies. With a total length of 1.0 meter and a weight of 0.323 kg, this probe is both efficient and easy to handle.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 330103-01-04-10-02-05 |

| Type | 8 mm Proximity Probe |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Shaft Diameter | 8 mm |

| Operating Temperature | -40°C to +120°C |

| Range | 1-25 mil (0.0254-0.635 mm) |

| Mounting Type | Direct Mount |

| Measurement Principle | Eddy Current |

| Cable Length | 1.0 meter |

| Accuracy | ± 0.001 inch (± 0.0254 mm) |

Product Applications

The 330103-01-04-10-02-05 8 mm proximity probe finds application in industries that rely on continuous machinery condition monitoring. Some key applications include:

Power Generation: Used to monitor turbines, compressors, and generators, ensuring that early signs of malfunction, such as misalignment or imbalance, are detected before they cause costly failures.

Oil & Gas: Essential for monitoring rotating equipment such as pumps, compressors, and motors, the probe plays a key role in preventing operational downtime in offshore rigs, refineries, and pipelines.

Aerospace: Applied to turbines and engines in the aerospace industry, the probe ensures precise measurements to detect faults in mission-critical machinery.

Manufacturing: In factories, the probe is used to monitor production machinery such as conveyor belts and robotic arms, providing critical data that helps avoid expensive disruptions in the production line.

Marine: On ships and offshore platforms, the probe monitors engine performance, supporting maintenance strategies that ensure operational efficiency and safety.

Transportation: The 330103-01-04-10-02-05 probe is used in the transportation sector for condition monitoring of engines and other critical machinery, reducing downtime and enhancing reliability.

Product Advantages

High Precision: The 330103-01-04-10-02-05 probe offers an accuracy of ± 0.001 inch (± 0.0254 mm), allowing for highly reliable displacement and vibration measurements, critical for monitoring machinery health.

Durable Design: Capable of operating in environments with temperatures ranging from -40°C to +120°C, this probe is built to withstand extreme conditions, making it versatile and reliable in demanding industries.

Non-Contact Measurement: Utilizing eddy current technology, the probe measures displacement without physical contact, preventing wear and tear on both the probe and the monitored machinery.

Real-Time Monitoring: The probe continuously provides real-time data, offering early warnings of potential issues such as misalignment, imbalance, or mechanical wear, allowing for proactive maintenance actions.

Versatile Applications: With an 8 mm shaft diameter, the probe is designed for a wide range of machinery, including large turbines, compressors, and smaller motors, in various industries.

Cost-Efficient: The non-contact nature of the probe reduces the need for frequent maintenance and replacements, significantly lowering operational costs over time.

Enhanced Reliability: The probe’s ability to detect small changes in displacement and vibration helps ensure the reliability of machinery by providing early alerts to potential faults before they develop into major failures.

Easy Integration: Compatible with the 3300 XL vibration monitoring system, the probe integrates seamlessly with other components for comprehensive machine condition monitoring.

Low Maintenance: As a non-contact probe, it experiences less wear, resulting in fewer service calls and prolonged operational life.

Long Lifespan: Designed for long-term use, the probe’s rugged construction ensures it performs reliably over many years, reducing the frequency of replacement.

Frequently Asked Questions (FAQ)

Q1: What technology does the 330103-01-04-10-02-05 probe use?

A1: The probe uses eddy current technology to measure displacement and vibration without physical contact, ensuring precision and minimizing wear.

Q2: What is the accuracy of the 330103-01-04-10-02-05 probe?

A2: The probe provides ± 0.001 inch (± 0.0254 mm) accuracy, ensuring highly accurate measurements for critical machinery monitoring.

Q3: What is the total length of this probe?

A3: The total length of the 330103-01-04-10-02-05 probe is 1.0 meter, making it suitable for a wide range of installation needs.

Q4: How much does the probe weigh?

A4: The probe weighs 0.323 kg, making it lightweight and easy to install and maintain.

Q5: What is the operating temperature range for this probe?

A5: The probe can operate within a temperature range of -40°C to +120°C, allowing it to function effectively in extreme environments.

Q6: How does the 330103-01-04-10-02-05 probe support predictive maintenance?

A6: By continuously monitoring displacement and vibration, the probe detects small changes in machine behavior, which are key indicators of potential failures, enabling predictive maintenance strategies.

Q7: In which industries can the 330103-01-04-10-02-05 probe be used?

A7: This probe is used in industries such as power generation, oil & gas, aerospace, manufacturing, marine, and transportation, providing critical condition monitoring for various types of rotating equipment.

Q8: How does non-contact measurement benefit this probe?

A8: Non-contact measurement eliminates wear on both the probe and the machinery being monitored, improving the overall lifespan and reducing the frequency of maintenance interventions.

Q9: Can this probe be used with other monitoring systems?

A9: While designed for use with the 3300 XL vibration monitoring system, it can also be integrated with other compatible machinery monitoring systems.

Q10: How does this probe help prevent machine failures?

A10: The probe detects early signs of misalignment, imbalance, and mechanical wear, allowing operators to perform corrective maintenance before major failures occur.

Bently Nevada 330103-01-04-10-02-05 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-01-04-10-02-05

Product Type:8 mm Proximity Probe

Origin:USA

Total Length:1.0 meter

Weight:0.323kg

Views:32

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-01-04-10-02-05 8 mm proximity probe is a highly reliable, precision measurement tool from the 3300 XL Series, designed to monitor displacement and vibration in industrial machinery. Using eddy current technology, this proximity probe can measure the relative position between a probe and a target with extreme precision, even in challenging operational environments.

The 330103-01-04-10-02-05 probe is commonly used in applications requiring high levels of accuracy in vibration monitoring, such as turbines, pumps, motors, and compressors. Its robust design and ability to operate in harsh conditions make it ideal for continuous monitoring of rotating equipment, ensuring early fault detection, minimizing downtime, and optimizing maintenance strategies. With a total length of 1.0 meter and a weight of 0.323 kg, this probe is both efficient and easy to handle.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 330103-01-04-10-02-05 |

| Type | 8 mm Proximity Probe |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Shaft Diameter | 8 mm |

| Operating Temperature | -40°C to +120°C |

| Range | 1-25 mil (0.0254-0.635 mm) |

| Mounting Type | Direct Mount |

| Measurement Principle | Eddy Current |

| Cable Length | 1.0 meter |

| Accuracy | ± 0.001 inch (± 0.0254 mm) |

Product Applications

The 330103-01-04-10-02-05 8 mm proximity probe finds application in industries that rely on continuous machinery condition monitoring. Some key applications include:

Power Generation: Used to monitor turbines, compressors, and generators, ensuring that early signs of malfunction, such as misalignment or imbalance, are detected before they cause costly failures.

Oil & Gas: Essential for monitoring rotating equipment such as pumps, compressors, and motors, the probe plays a key role in preventing operational downtime in offshore rigs, refineries, and pipelines.

Aerospace: Applied to turbines and engines in the aerospace industry, the probe ensures precise measurements to detect faults in mission-critical machinery.

Manufacturing: In factories, the probe is used to monitor production machinery such as conveyor belts and robotic arms, providing critical data that helps avoid expensive disruptions in the production line.

Marine: On ships and offshore platforms, the probe monitors engine performance, supporting maintenance strategies that ensure operational efficiency and safety.

Transportation: The 330103-01-04-10-02-05 probe is used in the transportation sector for condition monitoring of engines and other critical machinery, reducing downtime and enhancing reliability.

Product Advantages

High Precision: The 330103-01-04-10-02-05 probe offers an accuracy of ± 0.001 inch (± 0.0254 mm), allowing for highly reliable displacement and vibration measurements, critical for monitoring machinery health.

Durable Design: Capable of operating in environments with temperatures ranging from -40°C to +120°C, this probe is built to withstand extreme conditions, making it versatile and reliable in demanding industries.

Non-Contact Measurement: Utilizing eddy current technology, the probe measures displacement without physical contact, preventing wear and tear on both the probe and the monitored machinery.

Real-Time Monitoring: The probe continuously provides real-time data, offering early warnings of potential issues such as misalignment, imbalance, or mechanical wear, allowing for proactive maintenance actions.

Versatile Applications: With an 8 mm shaft diameter, the probe is designed for a wide range of machinery, including large turbines, compressors, and smaller motors, in various industries.

Cost-Efficient: The non-contact nature of the probe reduces the need for frequent maintenance and replacements, significantly lowering operational costs over time.

Enhanced Reliability: The probe’s ability to detect small changes in displacement and vibration helps ensure the reliability of machinery by providing early alerts to potential faults before they develop into major failures.

Easy Integration: Compatible with the 3300 XL vibration monitoring system, the probe integrates seamlessly with other components for comprehensive machine condition monitoring.

Low Maintenance: As a non-contact probe, it experiences less wear, resulting in fewer service calls and prolonged operational life.

Long Lifespan: Designed for long-term use, the probe’s rugged construction ensures it performs reliably over many years, reducing the frequency of replacement.

Frequently Asked Questions (FAQ)

Q1: What technology does the 330103-01-04-10-02-05 probe use?

A1: The probe uses eddy current technology to measure displacement and vibration without physical contact, ensuring precision and minimizing wear.

Q2: What is the accuracy of the 330103-01-04-10-02-05 probe?

A2: The probe provides ± 0.001 inch (± 0.0254 mm) accuracy, ensuring highly accurate measurements for critical machinery monitoring.

Q3: What is the total length of this probe?

A3: The total length of the 330103-01-04-10-02-05 probe is 1.0 meter, making it suitable for a wide range of installation needs.

Q4: How much does the probe weigh?

A4: The probe weighs 0.323 kg, making it lightweight and easy to install and maintain.

Q5: What is the operating temperature range for this probe?

A5: The probe can operate within a temperature range of -40°C to +120°C, allowing it to function effectively in extreme environments.

Q6: How does the 330103-01-04-10-02-05 probe support predictive maintenance?

A6: By continuously monitoring displacement and vibration, the probe detects small changes in machine behavior, which are key indicators of potential failures, enabling predictive maintenance strategies.

Q7: In which industries can the 330103-01-04-10-02-05 probe be used?

A7: This probe is used in industries such as power generation, oil & gas, aerospace, manufacturing, marine, and transportation, providing critical condition monitoring for various types of rotating equipment.

Q8: How does non-contact measurement benefit this probe?

A8: Non-contact measurement eliminates wear on both the probe and the machinery being monitored, improving the overall lifespan and reducing the frequency of maintenance interventions.

Q9: Can this probe be used with other monitoring systems?

A9: While designed for use with the 3300 XL vibration monitoring system, it can also be integrated with other compatible machinery monitoring systems.

Q10: How does this probe help prevent machine failures?

A10: The probe detects early signs of misalignment, imbalance, and mechanical wear, allowing operators to perform corrective maintenance before major failures occur.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...