Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

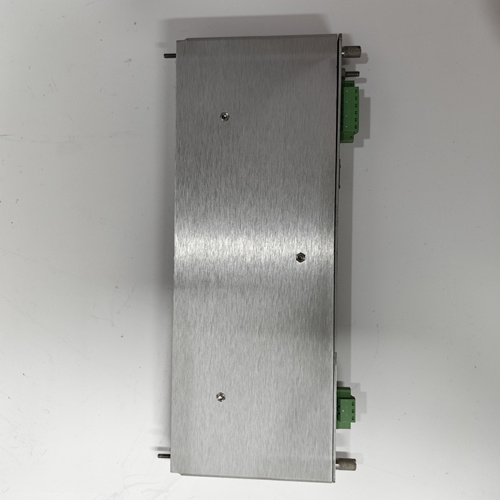

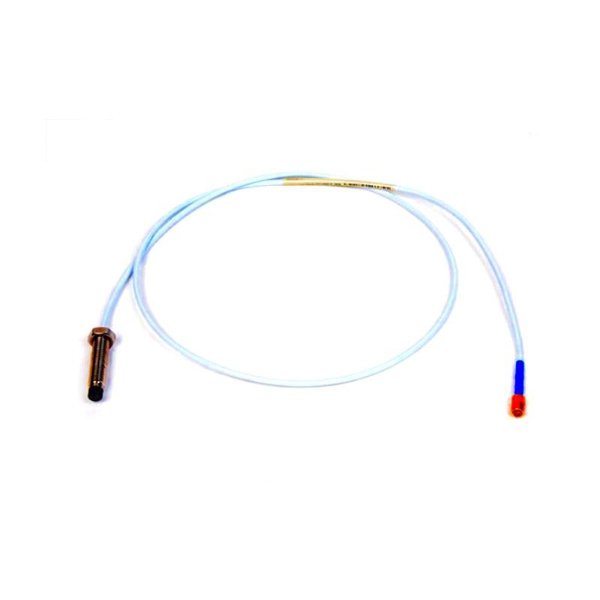

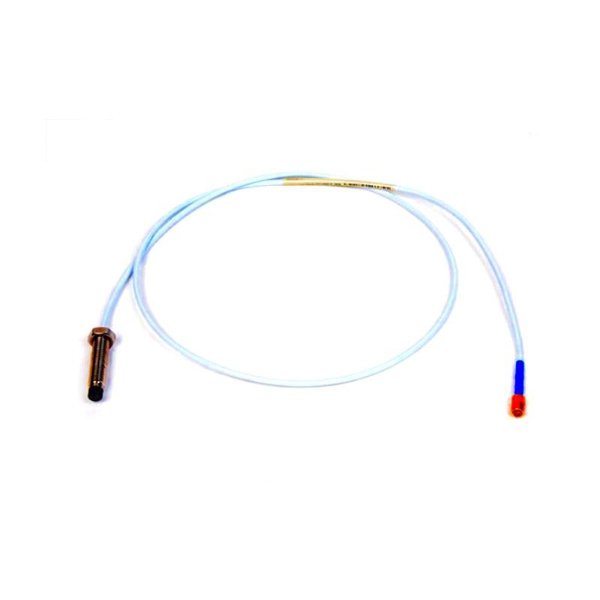

Bently Nevada 330101-00-52-15-02-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330101-00-52-15-02-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:1.5 meter

Weight:0.485 kg

Views:55

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-00-52-15-02-05 is a component of the 3300 XL 8 mm Proximity Transducer System. This system includes a proximity probe, extension cable, and Proximitor sensor. It measures static (position) and dynamic (vibration) variables in rotating machinery with fluid-film bearings. This model offers enhanced performance, superior EMI/RFI immunity, and complies with API 670 standards.

Applications

-

Axial thrust positioning

-

Keyphasor speed and phase reference

-

Turbomachinery diagnostics

-

Overspeed protection (with caution)

Advantages

-

API 670 compliance

-

Interchangeable probes, cables, and sensors

-

Patented TipLoc and CableLoc for durability

-

Extended temperature range capability

-

SpringLoc terminals for fast field wiring

-

High EMI/RFI immunity

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | 330101-00-52-15-02-05 |

| Probe Tip Diameter | 8 mm |

| System Type | Non-contacting eddy current proximity sensor |

| Total Length | 1.5 meters |

| Weight | 0.485 kg |

| Probe Material | AISI 303/304 stainless steel with PPS tip |

| Cable Type | 75 Ω triaxial, FEP insulated |

| Frequency Response | 0–10 kHz, ±3 dB |

| Linear Range | 2 mm (80 mils) |

| Operating Temperature | -52°C to +177°C (standard) / up to 218°C (ETR version) |

| Output Sensitivity | 200 mV/mil (7.87 V/mm) ±5% (5m system) |

| Supply Voltage | -17.5 Vdc to -26 Vdc |

| Minimum Shaft Diameter | 50.8 mm (2 in), recommended 76.2 mm (3 in) |

| Compliance | API 670, SIL 2/3, CE, RoHS, FCC, ATEX, IECEx |

FAQ

Q1: What does the 330101-00-52-15-02-05 probe measure?

A1: It measures both shaft vibration and position in fluid-film bearing machines.

Q2: Is it compatible with older 3300-series systems?

A2: Yes, it is backward-compatible and physically interchangeable with 3300 5 mm and 8 mm systems.

Q3: What is the output signal type?

A3: The output is an analog voltage directly proportional to the target distance.

Q4: Does this probe support high-temperature applications?

A4: Yes, ETR versions can operate up to +218°C.

Q5: What type of cable connection does it use?

A5: It uses gold-plated, corrosion-resistant ClickLoc coaxial connectors.

Q6: Can it be used for Keyphasor or speed measurements?

A6: Yes, it is suitable for Keyphasor and speed references, though overspeed protection requires caution.

Q7: Is the probe sealed against oil leakage?

A7: FluidLoc cable options prevent fluid migration through the cable.

Q8: Does it require special tools for installation?

A8: No, connectors and terminals are tool-free with ClickLoc and SpringLoc features.

Q9: What environments is the probe rated for?

A9: It is approved for hazardous zones including Class I, Division 2, and ATEX Zone 0/1/2.

Q10: What is the ideal gap setting?

A10: The recommended gap for radial vibration is approximately 1.27 mm (50 mils).

Bently Nevada 330101-00-52-15-02-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330101-00-52-15-02-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:1.5 meter

Weight:0.485 kg

Views:55

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-00-52-15-02-05 is a component of the 3300 XL 8 mm Proximity Transducer System. This system includes a proximity probe, extension cable, and Proximitor sensor. It measures static (position) and dynamic (vibration) variables in rotating machinery with fluid-film bearings. This model offers enhanced performance, superior EMI/RFI immunity, and complies with API 670 standards.

Applications

-

Axial thrust positioning

-

Keyphasor speed and phase reference

-

Turbomachinery diagnostics

-

Overspeed protection (with caution)

Advantages

-

API 670 compliance

-

Interchangeable probes, cables, and sensors

-

Patented TipLoc and CableLoc for durability

-

Extended temperature range capability

-

SpringLoc terminals for fast field wiring

-

High EMI/RFI immunity

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | 330101-00-52-15-02-05 |

| Probe Tip Diameter | 8 mm |

| System Type | Non-contacting eddy current proximity sensor |

| Total Length | 1.5 meters |

| Weight | 0.485 kg |

| Probe Material | AISI 303/304 stainless steel with PPS tip |

| Cable Type | 75 Ω triaxial, FEP insulated |

| Frequency Response | 0–10 kHz, ±3 dB |

| Linear Range | 2 mm (80 mils) |

| Operating Temperature | -52°C to +177°C (standard) / up to 218°C (ETR version) |

| Output Sensitivity | 200 mV/mil (7.87 V/mm) ±5% (5m system) |

| Supply Voltage | -17.5 Vdc to -26 Vdc |

| Minimum Shaft Diameter | 50.8 mm (2 in), recommended 76.2 mm (3 in) |

| Compliance | API 670, SIL 2/3, CE, RoHS, FCC, ATEX, IECEx |

FAQ

Q1: What does the 330101-00-52-15-02-05 probe measure?

A1: It measures both shaft vibration and position in fluid-film bearing machines.

Q2: Is it compatible with older 3300-series systems?

A2: Yes, it is backward-compatible and physically interchangeable with 3300 5 mm and 8 mm systems.

Q3: What is the output signal type?

A3: The output is an analog voltage directly proportional to the target distance.

Q4: Does this probe support high-temperature applications?

A4: Yes, ETR versions can operate up to +218°C.

Q5: What type of cable connection does it use?

A5: It uses gold-plated, corrosion-resistant ClickLoc coaxial connectors.

Q6: Can it be used for Keyphasor or speed measurements?

A6: Yes, it is suitable for Keyphasor and speed references, though overspeed protection requires caution.

Q7: Is the probe sealed against oil leakage?

A7: FluidLoc cable options prevent fluid migration through the cable.

Q8: Does it require special tools for installation?

A8: No, connectors and terminals are tool-free with ClickLoc and SpringLoc features.

Q9: What environments is the probe rated for?

A9: It is approved for hazardous zones including Class I, Division 2, and ATEX Zone 0/1/2.

Q10: What is the ideal gap setting?

A10: The recommended gap for radial vibration is approximately 1.27 mm (50 mils).

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...