Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

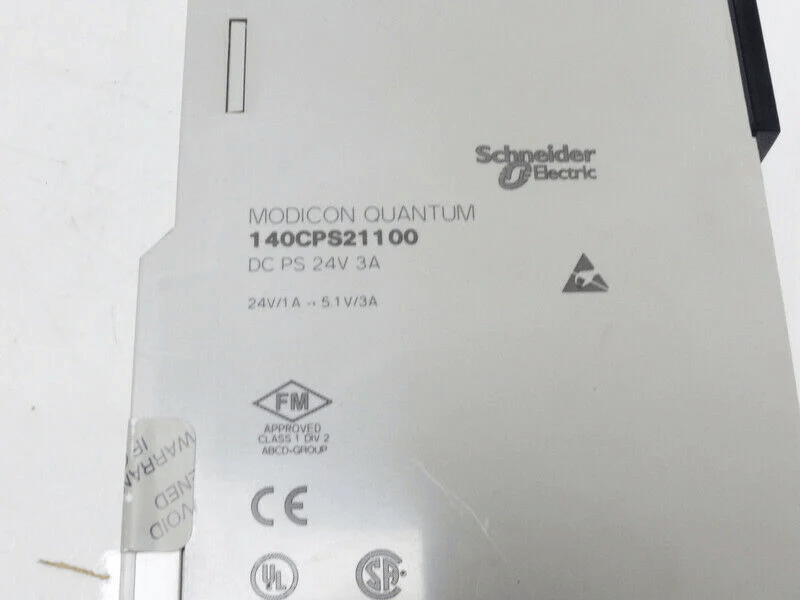

Schneider 140CRA21120C DIO Drop Interface

Manufacturer:Schneider

Product Number:140CRA21120C

Product Type:DIO Drop Interface

Origin:France

Package Size:50 ×165 ×315 mm

Package Weight:0.685 kg

Views:36

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Schneider Electric 140CRA21120C is a Distributed I/O (DIO) Drop Interface from the Modicon Quantum series, designed to support remote I/O communication architectures through S908 networks. It plays a critical role in extending Quantum PLC system capabilities by serving as the remote interface point between the CPU and distributed I/O racks.

As part of a modular and scalable system, the 140CRA21120C allows for flexible placement of I/O modules in geographically distributed or environmentally separated areas. This configuration is essential for large industrial plants, where centralized control is limited by physical or logistical constraints. Its solid build, fast data transfer rates, and seamless software compatibility make it a cornerstone component for high-performance automation systems.

The module’s design emphasizes reliability, speed, and expandability, ensuring communication consistency between the host system and remote I/O, even in harsh environments such as oil refineries, water treatment plants, and power generation facilities.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 140CRA21120C |

| Product Type | DIO Drop Interface |

| Product Series | Modicon Quantum |

| Network Type | Remote I/O (RIO) – S908 network |

| Communication Role | Remote drop sub-module |

| Data Transfer Rate | Up to 1.5 Mbps |

| Connection Type | BNC coaxial connector (75 Ohm impedance) |

| Number of Drops | 1 drop per module |

| Status Indicators | Module Status, Communication Activity, I/O Health |

| Installation | Plug-in to Quantum backplane |

| Programming Software | Unity Pro / EcoStruxure Control Expert |

| Power Supply | 5 V DC (from Quantum backplane) |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Certifications | CE, UL, CSA, RoHS, ATEX |

| Package size | 50 ×165 ×315 mm |

| Package Weight | 0.685 kg |

| Mounting Orientation | Vertical in backplane slot |

Product Applications

The 140CRA21120C is designed for use in remote I/O configurations, enabling field devices to interface with the central PLC controller in a decentralized manner. It’s used in a wide variety of applications:

Oil & Gas Facilities

Interfaces with remote sensors and actuators in field substations and platforms.

Water & Wastewater Management

Connects distributed pump stations, valves, and monitoring units to centralized control rooms.

Power Generation Plants

Provides remote interface for turbine auxiliaries, switchgear systems, and plant controls.

Process Manufacturing

Supports distributed skid units or field control devices in chemical, pharma, and food sectors.

Transportation Infrastructure

Manages I/O in remote facilities such as tunnels, rail control, or automated traffic systems.

Smart Buildings and Utilities

Extends automation to HVAC and electrical control panels located across large buildings or campuses.

Key Advantages

Reliable Remote I/O Extension

Enables effective expansion of Quantum PLC systems into distributed architectures without loss of control integrity.

Fast Data Transmission

Supports high-speed S908 communication protocol up to 1.5 Mbps, reducing response latency.

Easy Integration

Seamless compatibility with Unity Pro / EcoStruxure Control Expert ensures fast configuration and diagnostics.

Industrial-Grade Durability

Certified for harsh industrial environments, including ATEX-rated zones and high-vibration settings.

Compact and Lightweight Design

Space-efficient design suitable for cabinet-mounted systems with limited room.

Modular Scalability

Supports system expansion via simple plug-in interface, ideal for growing automation demands.

Global Compliance

Certified under multiple industrial safety and performance standards for universal deployment.

Frequently Asked Questions (FAQ)

1. What is the purpose of the 140CRA21120C module?

It serves as a sub-interface for connecting a remote I/O drop to the main Quantum PLC controller over a remote I/O (RIO) network.

2. Can it be used with any Modicon Quantum CPU?

Yes, provided the CPU supports RIO communication architecture.

3. What cable type is required for RIO communication?

A BNC coaxial cable with 75 Ohm impedance is typically used.

4. Does it support redundancy?

While the module itself is not redundant, it can be deployed in systems that utilize redundant network paths or CPUs.

5. How many remote drops can it support?

Each 140CRA21120C supports a single drop; multiple modules are used for multiple drops.

6. Is it hot-swappable?

No, the module should only be inserted or removed with the system powered down.

7. How is the module powered?

It receives 5 V DC from the Quantum backplane power supply.

8. Does it support diagnostics?

Yes, LED indicators and software tools offer real-time diagnostics on communication and module health.

9. What is the maximum operating temperature?

It operates reliably up to +60°C.

10. Which software is used to configure the module?

Unity Pro or EcoStruxure Control Expert by Schneider Electric.

Schneider 140CRA21120C DIO Drop Interface

Manufacturer:Schneider

Product Number:140CRA21120C

Product Type:DIO Drop Interface

Origin:France

Package Size:50 ×165 ×315 mm

Package Weight:0.685 kg

Views:36

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Schneider Electric 140CRA21120C is a Distributed I/O (DIO) Drop Interface from the Modicon Quantum series, designed to support remote I/O communication architectures through S908 networks. It plays a critical role in extending Quantum PLC system capabilities by serving as the remote interface point between the CPU and distributed I/O racks.

As part of a modular and scalable system, the 140CRA21120C allows for flexible placement of I/O modules in geographically distributed or environmentally separated areas. This configuration is essential for large industrial plants, where centralized control is limited by physical or logistical constraints. Its solid build, fast data transfer rates, and seamless software compatibility make it a cornerstone component for high-performance automation systems.

The module’s design emphasizes reliability, speed, and expandability, ensuring communication consistency between the host system and remote I/O, even in harsh environments such as oil refineries, water treatment plants, and power generation facilities.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 140CRA21120C |

| Product Type | DIO Drop Interface |

| Product Series | Modicon Quantum |

| Network Type | Remote I/O (RIO) – S908 network |

| Communication Role | Remote drop sub-module |

| Data Transfer Rate | Up to 1.5 Mbps |

| Connection Type | BNC coaxial connector (75 Ohm impedance) |

| Number of Drops | 1 drop per module |

| Status Indicators | Module Status, Communication Activity, I/O Health |

| Installation | Plug-in to Quantum backplane |

| Programming Software | Unity Pro / EcoStruxure Control Expert |

| Power Supply | 5 V DC (from Quantum backplane) |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Certifications | CE, UL, CSA, RoHS, ATEX |

| Package size | 50 ×165 ×315 mm |

| Package Weight | 0.685 kg |

| Mounting Orientation | Vertical in backplane slot |

Product Applications

The 140CRA21120C is designed for use in remote I/O configurations, enabling field devices to interface with the central PLC controller in a decentralized manner. It’s used in a wide variety of applications:

Oil & Gas Facilities

Interfaces with remote sensors and actuators in field substations and platforms.

Water & Wastewater Management

Connects distributed pump stations, valves, and monitoring units to centralized control rooms.

Power Generation Plants

Provides remote interface for turbine auxiliaries, switchgear systems, and plant controls.

Process Manufacturing

Supports distributed skid units or field control devices in chemical, pharma, and food sectors.

Transportation Infrastructure

Manages I/O in remote facilities such as tunnels, rail control, or automated traffic systems.

Smart Buildings and Utilities

Extends automation to HVAC and electrical control panels located across large buildings or campuses.

Key Advantages

Reliable Remote I/O Extension

Enables effective expansion of Quantum PLC systems into distributed architectures without loss of control integrity.

Fast Data Transmission

Supports high-speed S908 communication protocol up to 1.5 Mbps, reducing response latency.

Easy Integration

Seamless compatibility with Unity Pro / EcoStruxure Control Expert ensures fast configuration and diagnostics.

Industrial-Grade Durability

Certified for harsh industrial environments, including ATEX-rated zones and high-vibration settings.

Compact and Lightweight Design

Space-efficient design suitable for cabinet-mounted systems with limited room.

Modular Scalability

Supports system expansion via simple plug-in interface, ideal for growing automation demands.

Global Compliance

Certified under multiple industrial safety and performance standards for universal deployment.

Frequently Asked Questions (FAQ)

1. What is the purpose of the 140CRA21120C module?

It serves as a sub-interface for connecting a remote I/O drop to the main Quantum PLC controller over a remote I/O (RIO) network.

2. Can it be used with any Modicon Quantum CPU?

Yes, provided the CPU supports RIO communication architecture.

3. What cable type is required for RIO communication?

A BNC coaxial cable with 75 Ohm impedance is typically used.

4. Does it support redundancy?

While the module itself is not redundant, it can be deployed in systems that utilize redundant network paths or CPUs.

5. How many remote drops can it support?

Each 140CRA21120C supports a single drop; multiple modules are used for multiple drops.

6. Is it hot-swappable?

No, the module should only be inserted or removed with the system powered down.

7. How is the module powered?

It receives 5 V DC from the Quantum backplane power supply.

8. Does it support diagnostics?

Yes, LED indicators and software tools offer real-time diagnostics on communication and module health.

9. What is the maximum operating temperature?

It operates reliably up to +60°C.

10. Which software is used to configure the module?

Unity Pro or EcoStruxure Control Expert by Schneider Electric.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...