Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

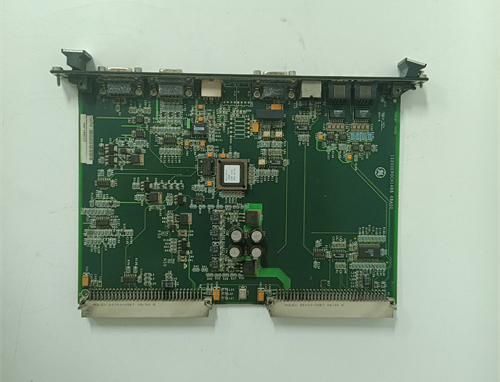

General Electric IC660EBD110 I/O Block Electronic Assembly

Manufacturer:GE

Product Number:IC660EBD110

Product Type:I/O Block Electronic Assembly

Origin:USA

Dimensions:224.4 x 88.9 x 100 mm

Weight:1.8 kg

Views:49

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IC660EBD110 I/O Block Electronic Assembly is a vital electronic interface module designed for the GE Fanuc Series 90-30 programmable logic controller (PLC) system. Serving as a robust communication link, this I/O block facilitates seamless data transfer between the CPU module and various input/output modules installed within the control system chassis.

Engineered with precision and reliability in mind, the IC660EBD110 ensures stable and efficient communication on the backplane, supporting a broad range of digital and analog I/O modules. Its durable construction allows it to perform consistently in challenging industrial environments, making it a preferred choice for automation professionals who demand reliability and longevity.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | IC660EBD110 |

| Manufacturer | General Electric (GE Fanuc) |

| Product Type | I/O Block Electronic Assembly |

| Compatible System | GE Fanuc Series 90-30 PLC |

| Function | Backplane communication and interface |

| Power Supply Voltage | 5 VDC regulated |

| Input Voltage Range | 4.75 V to 5.25 V |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to 85°C |

| Humidity Range | 5% to 95% non-condensing |

| Dimensions (H × W × D) | 224.4 x 88.9 x 100 mm |

| Weight | 1.8 kg |

| Mounting | DIN Rail or Chassis Slot |

| Certifications | UL Listed, CE Marked |

| Environmental Protection | IP20 |

Product Applications

The IC660EBD110 is broadly used in industrial automation setups where reliable and precise communication between the PLC CPU and I/O modules is essential. Its applications include:

Automotive Manufacturing: Controls assembly lines, robotic stations, and conveyor systems for efficient production flow.

Chemical Processing: Monitors and controls sensors and actuators in harsh chemical plant environments.

Food and Beverage: Ensures hygienic and precise automation for filling, packaging, and processing machinery.

Energy and Utilities: Manages distributed control systems for power generation, water treatment, and distribution networks.

Material Handling: Automates conveyors, sorters, and packaging equipment in warehouses and logistics centers.

Building Automation: Integrates lighting, HVAC, and security systems for large commercial and industrial buildings.

Product Advantages

Reliable Backplane Interface: Provides stable communication across multiple I/O modules ensuring system integrity.

Compact Size: Space-saving design enables high-density installations in tight control cabinets.

Wide Environmental Tolerance: Operates effectively in temperatures ranging from 0°C to 60°C and in high humidity environments.

Easy Installation: Supports standard DIN rail or chassis mounting options for quick deployment.

Low Power Consumption: Efficient circuitry reduces overall energy use in automation systems.

Robust Build Quality: Designed to withstand industrial vibrations and electrical noise.

Comprehensive Diagnostics: Facilitates easy fault detection and system troubleshooting.

Certified Safety and Compliance: Meets UL and CE requirements for safety and electromagnetic compatibility.

Versatile Compatibility: Supports various digital and analog I/O modules from the Series 90-30 family.

Proven Industry Track Record: Trusted by industrial professionals worldwide for critical control applications.

Frequently Asked Questions (FAQ)

What role does the IC660EBD110 serve in the Series 90-30 PLC system?

It acts as the electronic communication interface between the CPU and the I/O modules.

Is this module compatible with other PLC systems besides Series 90-30?

No, it is specifically designed for the GE Fanuc Series 90-30 platform.

What power supply voltage does the IC660EBD110 require?

It operates on a regulated 5 VDC power supply, typically provided by the PLC chassis.

Can this module be used in environments with high humidity?

Yes, it operates reliably in up to 95% relative humidity, non-condensing.

What are the physical dimensions of the module?

The module measures 224.4 x 88.9 x 100 mm.

How is the module installed?

Installation can be done on DIN rails or into designated chassis slots.

Does the module support diagnostic functions?

Yes, it includes electronic monitoring features to help with fault detection.

What certifications does the IC660EBD110 hold?

It is UL Listed and CE Marked, ensuring compliance with safety and EMC standards.

What is the expected lifespan of this module in industrial settings?

When used properly, the module is designed for long-term operation, typically several years under normal industrial conditions.

Can the module be replaced without shutting down the entire system?

Replacement procedures depend on system design, but typically power-down is required to ensure safety and avoid communication errors.

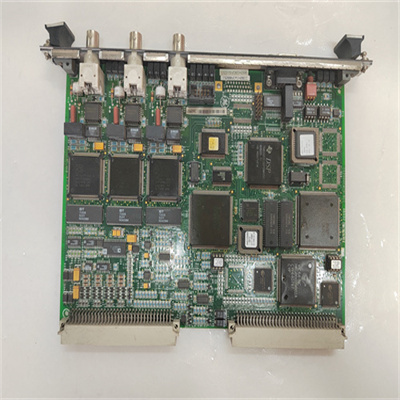

General Electric IC660EBD110 I/O Block Electronic Assembly

Manufacturer:GE

Product Number:IC660EBD110

Product Type:I/O Block Electronic Assembly

Origin:USA

Dimensions:224.4 x 88.9 x 100 mm

Weight:1.8 kg

Views:49

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IC660EBD110 I/O Block Electronic Assembly is a vital electronic interface module designed for the GE Fanuc Series 90-30 programmable logic controller (PLC) system. Serving as a robust communication link, this I/O block facilitates seamless data transfer between the CPU module and various input/output modules installed within the control system chassis.

Engineered with precision and reliability in mind, the IC660EBD110 ensures stable and efficient communication on the backplane, supporting a broad range of digital and analog I/O modules. Its durable construction allows it to perform consistently in challenging industrial environments, making it a preferred choice for automation professionals who demand reliability and longevity.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | IC660EBD110 |

| Manufacturer | General Electric (GE Fanuc) |

| Product Type | I/O Block Electronic Assembly |

| Compatible System | GE Fanuc Series 90-30 PLC |

| Function | Backplane communication and interface |

| Power Supply Voltage | 5 VDC regulated |

| Input Voltage Range | 4.75 V to 5.25 V |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to 85°C |

| Humidity Range | 5% to 95% non-condensing |

| Dimensions (H × W × D) | 224.4 x 88.9 x 100 mm |

| Weight | 1.8 kg |

| Mounting | DIN Rail or Chassis Slot |

| Certifications | UL Listed, CE Marked |

| Environmental Protection | IP20 |

Product Applications

The IC660EBD110 is broadly used in industrial automation setups where reliable and precise communication between the PLC CPU and I/O modules is essential. Its applications include:

Automotive Manufacturing: Controls assembly lines, robotic stations, and conveyor systems for efficient production flow.

Chemical Processing: Monitors and controls sensors and actuators in harsh chemical plant environments.

Food and Beverage: Ensures hygienic and precise automation for filling, packaging, and processing machinery.

Energy and Utilities: Manages distributed control systems for power generation, water treatment, and distribution networks.

Material Handling: Automates conveyors, sorters, and packaging equipment in warehouses and logistics centers.

Building Automation: Integrates lighting, HVAC, and security systems for large commercial and industrial buildings.

Product Advantages

Reliable Backplane Interface: Provides stable communication across multiple I/O modules ensuring system integrity.

Compact Size: Space-saving design enables high-density installations in tight control cabinets.

Wide Environmental Tolerance: Operates effectively in temperatures ranging from 0°C to 60°C and in high humidity environments.

Easy Installation: Supports standard DIN rail or chassis mounting options for quick deployment.

Low Power Consumption: Efficient circuitry reduces overall energy use in automation systems.

Robust Build Quality: Designed to withstand industrial vibrations and electrical noise.

Comprehensive Diagnostics: Facilitates easy fault detection and system troubleshooting.

Certified Safety and Compliance: Meets UL and CE requirements for safety and electromagnetic compatibility.

Versatile Compatibility: Supports various digital and analog I/O modules from the Series 90-30 family.

Proven Industry Track Record: Trusted by industrial professionals worldwide for critical control applications.

Frequently Asked Questions (FAQ)

What role does the IC660EBD110 serve in the Series 90-30 PLC system?

It acts as the electronic communication interface between the CPU and the I/O modules.

Is this module compatible with other PLC systems besides Series 90-30?

No, it is specifically designed for the GE Fanuc Series 90-30 platform.

What power supply voltage does the IC660EBD110 require?

It operates on a regulated 5 VDC power supply, typically provided by the PLC chassis.

Can this module be used in environments with high humidity?

Yes, it operates reliably in up to 95% relative humidity, non-condensing.

What are the physical dimensions of the module?

The module measures 224.4 x 88.9 x 100 mm.

How is the module installed?

Installation can be done on DIN rails or into designated chassis slots.

Does the module support diagnostic functions?

Yes, it includes electronic monitoring features to help with fault detection.

What certifications does the IC660EBD110 hold?

It is UL Listed and CE Marked, ensuring compliance with safety and EMC standards.

What is the expected lifespan of this module in industrial settings?

When used properly, the module is designed for long-term operation, typically several years under normal industrial conditions.

Can the module be replaced without shutting down the entire system?

Replacement procedures depend on system design, but typically power-down is required to ensure safety and avoid communication errors.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...