Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

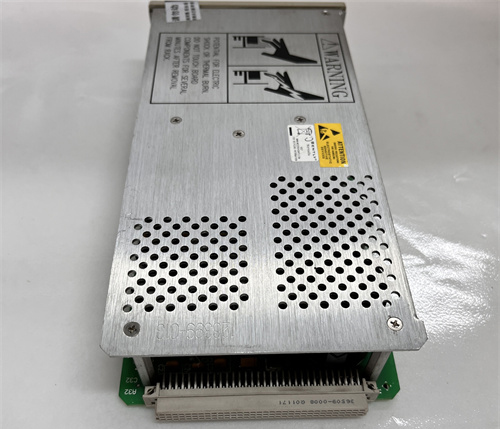

Bently Nevada 330101-00-44-10-02-05 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330101-00-44-10-02-05

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:1 meter

Weight:0.323 kg

Views:76

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-00-44-10-02-05 3300 XL Proximity Probe is a precision sensor designed for the continuous measurement of shaft vibration and position in rotating machinery. It is part of the renowned 3300 XL series, known for its ruggedness, high reliability, and long-term stability in harsh industrial environments.

This model features an 8 mm probe gap, optimized for accuracy and repeatability in applications such as turbine monitoring, compressor diagnostics, and large motor protection. The probe uses eddy-current technology to detect shaft movement without physical contact, allowing it to monitor critical machinery components to prevent failures and minimize downtime.

With robust construction designed to resist contamination, temperature variations, and vibration, the 3300 XL probes provide operators with trusted condition data essential for predictive maintenance strategies.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 330101-00-44-10-02-05 |

| Product Series | 3300 XL |

| Probe Type | Proximity Probe (Eddy Current) |

| Sensing Gap | 8 mm |

| Total Length | 1 meter |

| Operating Temperature | -40°C to +120°C |

| Measurement Range | ±0.25 mm (typical) |

| Frequency Response | DC to 20 kHz |

| Output Signal | AC variable frequency output proportional to gap |

| Connector Type | 6-pin military-style connector |

| Probe Housing Material | Stainless Steel |

| Weight | 0.323 kg |

| Environmental Rating | IP67 |

| Installation Type | Threaded mounting, 3/8-24 UNF standard thread |

| Manufacturer | Bently Nevada (a Baker Hughes business) |

Applications

The 3300 XL 8mm Proximity Probe is widely used across industries for monitoring rotating equipment where precise shaft position and vibration measurements are critical:

Power Generation: Turbine shaft vibration and position monitoring

Oil & Gas: Compressors and pumps shaft position feedback for reliability

Aerospace Manufacturing: Test stands for engines and turbines

Pulp & Paper: Large motor and gearbox vibration monitoring

Metals & Mining: Crushers and conveyor belt motor condition monitoring

Chemical Processing: Pumps and mixers requiring early fault detection

Product Advantages

High Sensitivity and Accuracy: Eddy current technology with 8mm gap for precise position sensing.

Rugged Construction: Stainless steel housing and IP67 rating provide protection against dust, moisture, and harsh conditions.

Wide Temperature Range: Reliable operation from -40°C to +120°C supports many industrial environments.

Easy Installation: Standardized threaded mounting ensures straightforward and secure fitting.

Long Cable Options: Flexible cable length configurations help accommodate complex plant layouts.

Low Maintenance: Non-contact measurement reduces wear and need for sensor replacement.

Compatibility: Designed to integrate with Bently Nevada 3300 XL monitoring systems and other industry-standard vibration monitoring equipment.

Industry Proven: Trusted brand with decades of field performance and support.

Frequently Asked Questions (FAQ)

1. What is the significance of the 8 mm sensing gap in this proximity probe?

The 8 mm gap allows the probe to detect shaft movement accurately while providing enough clearance to prevent physical contact and sensor damage.

2. How does the probe measure shaft position without contact?

It uses eddy current technology, generating a magnetic field that changes with the distance to the conductive target (shaft), producing a signal proportional to shaft displacement.

3. Can the probe operate in environments with high moisture or dust?

Yes, the probe’s IP67 rating means it is dust-tight and protected against temporary immersion in water, suitable for harsh industrial conditions.

4. Is this probe compatible with other Bently Nevada 3300 series systems?

Yes, it is designed to work seamlessly with 3300 XL monitors and other compatible vibration monitoring systems.

5. What are typical total length options for this probe?

Total cables are 1 meter, but custom lengths are available to meet specific installation requirements.

6. How does temperature affect the probe’s operation?

The probe is rated to operate reliably from -40°C to +120°C, maintaining accuracy across this wide temperature range.

7. What maintenance does the probe require?

Since it operates without physical contact, maintenance is minimal, primarily ensuring connectors and cables are intact and clean.

8. How is the probe mounted on machinery?

The probe features a standard 3/8-24 UNF threaded housing allowing secure, repeatable mounting in probe holders or directly into equipment.

9. What kind of output signal does the probe provide?

It produces an AC variable frequency signal proportional to the distance between the probe tip and the shaft surface.

10. Can this probe be used in explosive environments?

While robust, installation in explosive atmospheres requires compliance with local hazardous area standards and may need additional protective housings or certifications.

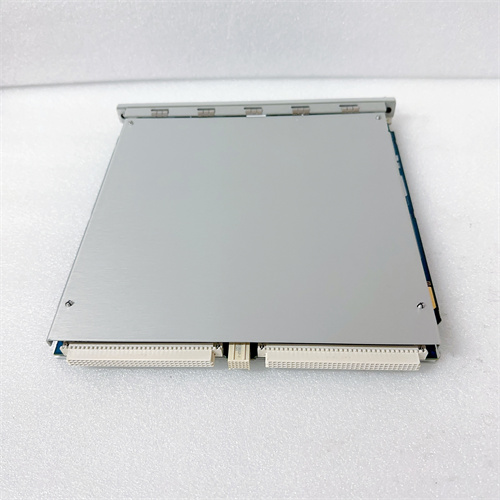

Bently Nevada 330101-00-44-10-02-05 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330101-00-44-10-02-05

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:1 meter

Weight:0.323 kg

Views:76

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-00-44-10-02-05 3300 XL Proximity Probe is a precision sensor designed for the continuous measurement of shaft vibration and position in rotating machinery. It is part of the renowned 3300 XL series, known for its ruggedness, high reliability, and long-term stability in harsh industrial environments.

This model features an 8 mm probe gap, optimized for accuracy and repeatability in applications such as turbine monitoring, compressor diagnostics, and large motor protection. The probe uses eddy-current technology to detect shaft movement without physical contact, allowing it to monitor critical machinery components to prevent failures and minimize downtime.

With robust construction designed to resist contamination, temperature variations, and vibration, the 3300 XL probes provide operators with trusted condition data essential for predictive maintenance strategies.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 330101-00-44-10-02-05 |

| Product Series | 3300 XL |

| Probe Type | Proximity Probe (Eddy Current) |

| Sensing Gap | 8 mm |

| Total Length | 1 meter |

| Operating Temperature | -40°C to +120°C |

| Measurement Range | ±0.25 mm (typical) |

| Frequency Response | DC to 20 kHz |

| Output Signal | AC variable frequency output proportional to gap |

| Connector Type | 6-pin military-style connector |

| Probe Housing Material | Stainless Steel |

| Weight | 0.323 kg |

| Environmental Rating | IP67 |

| Installation Type | Threaded mounting, 3/8-24 UNF standard thread |

| Manufacturer | Bently Nevada (a Baker Hughes business) |

Applications

The 3300 XL 8mm Proximity Probe is widely used across industries for monitoring rotating equipment where precise shaft position and vibration measurements are critical:

Power Generation: Turbine shaft vibration and position monitoring

Oil & Gas: Compressors and pumps shaft position feedback for reliability

Aerospace Manufacturing: Test stands for engines and turbines

Pulp & Paper: Large motor and gearbox vibration monitoring

Metals & Mining: Crushers and conveyor belt motor condition monitoring

Chemical Processing: Pumps and mixers requiring early fault detection

Product Advantages

High Sensitivity and Accuracy: Eddy current technology with 8mm gap for precise position sensing.

Rugged Construction: Stainless steel housing and IP67 rating provide protection against dust, moisture, and harsh conditions.

Wide Temperature Range: Reliable operation from -40°C to +120°C supports many industrial environments.

Easy Installation: Standardized threaded mounting ensures straightforward and secure fitting.

Long Cable Options: Flexible cable length configurations help accommodate complex plant layouts.

Low Maintenance: Non-contact measurement reduces wear and need for sensor replacement.

Compatibility: Designed to integrate with Bently Nevada 3300 XL monitoring systems and other industry-standard vibration monitoring equipment.

Industry Proven: Trusted brand with decades of field performance and support.

Frequently Asked Questions (FAQ)

1. What is the significance of the 8 mm sensing gap in this proximity probe?

The 8 mm gap allows the probe to detect shaft movement accurately while providing enough clearance to prevent physical contact and sensor damage.

2. How does the probe measure shaft position without contact?

It uses eddy current technology, generating a magnetic field that changes with the distance to the conductive target (shaft), producing a signal proportional to shaft displacement.

3. Can the probe operate in environments with high moisture or dust?

Yes, the probe’s IP67 rating means it is dust-tight and protected against temporary immersion in water, suitable for harsh industrial conditions.

4. Is this probe compatible with other Bently Nevada 3300 series systems?

Yes, it is designed to work seamlessly with 3300 XL monitors and other compatible vibration monitoring systems.

5. What are typical total length options for this probe?

Total cables are 1 meter, but custom lengths are available to meet specific installation requirements.

6. How does temperature affect the probe’s operation?

The probe is rated to operate reliably from -40°C to +120°C, maintaining accuracy across this wide temperature range.

7. What maintenance does the probe require?

Since it operates without physical contact, maintenance is minimal, primarily ensuring connectors and cables are intact and clean.

8. How is the probe mounted on machinery?

The probe features a standard 3/8-24 UNF threaded housing allowing secure, repeatable mounting in probe holders or directly into equipment.

9. What kind of output signal does the probe provide?

It produces an AC variable frequency signal proportional to the distance between the probe tip and the shaft surface.

10. Can this probe be used in explosive environments?

While robust, installation in explosive atmospheres requires compliance with local hazardous area standards and may need additional protective housings or certifications.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...