Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

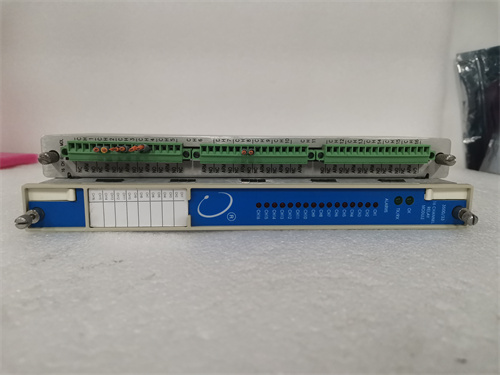

Bently Nevada 330101-00-44-05-02-RU 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330101-00-44-05-02-RU

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:0.5 meter

Weight:0.162kg

Views:59

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-00-44-05-02-RU 3300 XL 8 mm Proximity Probe is a high-precision sensor designed to measure shaft displacement and vibration in rotating machinery. As part of the 3300 XL Series, this probe offers excellent reliability and accuracy, making it ideal for critical machinery monitoring in industries such as oil & gas, power generation, and chemical processing.

This probe provides real-time data, allowing operators to detect imbalances, misalignments, and bearing wear early, preventing costly repairs and downtime. With a durable stainless steel construction, the 3300 XL 8 mm Proximity Probe is built to withstand harsh conditions, ensuring long-term performance in industrial environments.

Product Parameters

| Parameter | Specification |

|---|---|

| Probe Type | 3300 XL 8 mm Proximity Probe |

| Total Length | 0.5 meter |

| Weight | 0.162 kg |

| Sensing Range | 8 mm |

| Material | Stainless Steel |

| Output | 4-20 mA, Differential |

| Accuracy | ±0.001 mm |

| Operating Temperature | -40 to +85°C |

Applications

The 3300 XL 8 mm Proximity Probe is used for various machinery monitoring applications:

-

Shaft Vibration Monitoring: Detects imbalances and misalignments in rotating machinery.

-

Rotor Position Monitoring: Measures rotor displacement in turbines, compressors, and other equipment.

-

Bearing Health Monitoring: Identifies early signs of bearing wear and prevents failure.

-

Turbine and Compressor Monitoring: Helps ensure smooth operation of turbines and compressors.

This probe is commonly used in oil & gas, power generation, and chemical industries.

Advantages

-

High Accuracy: Measures displacement with ±0.001 mm precision.

-

Durable Design: Made from stainless steel, it resists wear and corrosion.

-

Real-time Monitoring: Provides immediate feedback on machinery condition.

-

High Sensitivity: Detects even small changes in vibration and displacement.

-

Vibration Resistance: Performs reliably in high-vibration environments.

-

Seamless Integration: Works well with other Bently Nevada systems like the 3500 Series.

FAQ

1. What is the sensing range of the 3300 XL 8 mm Proximity Probe?

The probe measures shaft displacement up to 8 mm.

2. What type of output does the 3300 XL 8 mm Proximity Probe provide?

It provides a 4-20 mA differential output.

3. How accurate is the 3300 XL 8 mm Proximity Probe?

The probe has an accuracy of ±0.001 mm.

4. Can the 3300 XL 8 mm Proximity Probe work in extreme temperatures?

Yes, it operates within a range of -40°C to +85°C.

5. How does the 3300 XL 8 mm Proximity Probe handle high-vibration conditions?

It is designed to operate reliably in high-vibration environments.

6. What material is the 3300 XL 8 mm Proximity Probe made of?

The probe is made of stainless steel for durability.

7. Is the 3300 XL 8 mm Proximity Probe suitable for turbine monitoring?

Yes, it is commonly used for turbine and compressor monitoring.

8. How sensitive is the 3300 XL 8 mm Proximity Probe?

It detects small changes in displacement with high sensitivity.

9. Can the 3300 XL 8 mm Proximity Probe be integrated with other Bently Nevada systems?

Yes, it works well with other systems like the 3500 Series.

10. How is the 3300 XL 8 mm Proximity Probe installed?

It is mounted on the machine and connected to the monitoring system.

Bently Nevada 330101-00-44-05-02-RU 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330101-00-44-05-02-RU

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:0.5 meter

Weight:0.162kg

Views:59

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-00-44-05-02-RU 3300 XL 8 mm Proximity Probe is a high-precision sensor designed to measure shaft displacement and vibration in rotating machinery. As part of the 3300 XL Series, this probe offers excellent reliability and accuracy, making it ideal for critical machinery monitoring in industries such as oil & gas, power generation, and chemical processing.

This probe provides real-time data, allowing operators to detect imbalances, misalignments, and bearing wear early, preventing costly repairs and downtime. With a durable stainless steel construction, the 3300 XL 8 mm Proximity Probe is built to withstand harsh conditions, ensuring long-term performance in industrial environments.

Product Parameters

| Parameter | Specification |

|---|---|

| Probe Type | 3300 XL 8 mm Proximity Probe |

| Total Length | 0.5 meter |

| Weight | 0.162 kg |

| Sensing Range | 8 mm |

| Material | Stainless Steel |

| Output | 4-20 mA, Differential |

| Accuracy | ±0.001 mm |

| Operating Temperature | -40 to +85°C |

Applications

The 3300 XL 8 mm Proximity Probe is used for various machinery monitoring applications:

-

Shaft Vibration Monitoring: Detects imbalances and misalignments in rotating machinery.

-

Rotor Position Monitoring: Measures rotor displacement in turbines, compressors, and other equipment.

-

Bearing Health Monitoring: Identifies early signs of bearing wear and prevents failure.

-

Turbine and Compressor Monitoring: Helps ensure smooth operation of turbines and compressors.

This probe is commonly used in oil & gas, power generation, and chemical industries.

Advantages

-

High Accuracy: Measures displacement with ±0.001 mm precision.

-

Durable Design: Made from stainless steel, it resists wear and corrosion.

-

Real-time Monitoring: Provides immediate feedback on machinery condition.

-

High Sensitivity: Detects even small changes in vibration and displacement.

-

Vibration Resistance: Performs reliably in high-vibration environments.

-

Seamless Integration: Works well with other Bently Nevada systems like the 3500 Series.

FAQ

1. What is the sensing range of the 3300 XL 8 mm Proximity Probe?

The probe measures shaft displacement up to 8 mm.

2. What type of output does the 3300 XL 8 mm Proximity Probe provide?

It provides a 4-20 mA differential output.

3. How accurate is the 3300 XL 8 mm Proximity Probe?

The probe has an accuracy of ±0.001 mm.

4. Can the 3300 XL 8 mm Proximity Probe work in extreme temperatures?

Yes, it operates within a range of -40°C to +85°C.

5. How does the 3300 XL 8 mm Proximity Probe handle high-vibration conditions?

It is designed to operate reliably in high-vibration environments.

6. What material is the 3300 XL 8 mm Proximity Probe made of?

The probe is made of stainless steel for durability.

7. Is the 3300 XL 8 mm Proximity Probe suitable for turbine monitoring?

Yes, it is commonly used for turbine and compressor monitoring.

8. How sensitive is the 3300 XL 8 mm Proximity Probe?

It detects small changes in displacement with high sensitivity.

9. Can the 3300 XL 8 mm Proximity Probe be integrated with other Bently Nevada systems?

Yes, it works well with other systems like the 3500 Series.

10. How is the 3300 XL 8 mm Proximity Probe installed?

It is mounted on the machine and connected to the monitoring system.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...