Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

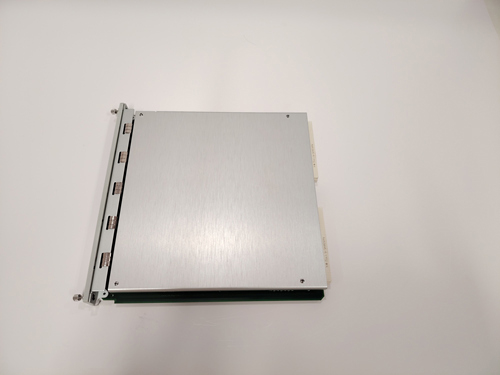

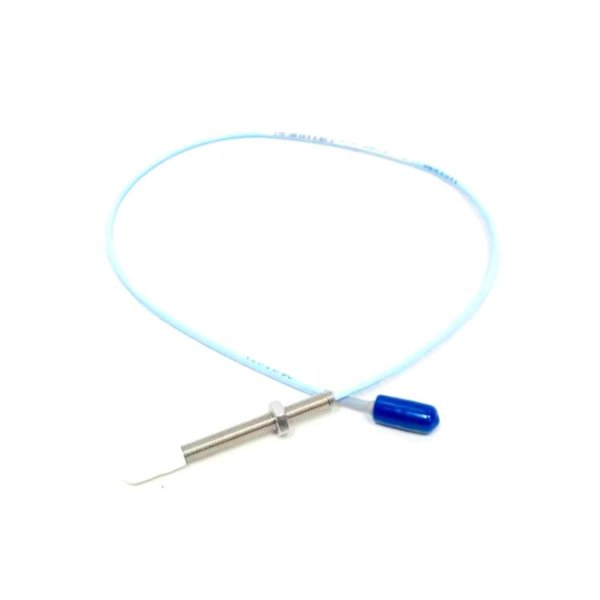

Bently Nevada 330901-05-32-05-02-00 3300 NSv Proximity Probe

Manufacturer:Bently Nevada

Product Number:330901-05-32-05-02-00

Product Type:3300 NSv Proximity Probe

Origin:USA

Total Length:0.5 m

Weight :3 kg

Views:49

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330901-05-32-05-02-00, 3300 NSv Proximity Probe is a highly reliable transducer used for shaft vibration and position measurements in rotating machinery. It belongs to the 3300 NSv (Narrow Side-view) probe series, which was specifically designed for applications where smaller probe dimensions are required without sacrificing accuracy. This model provides precise measurement of dynamic and static displacements, ensuring accurate monitoring and protection of critical assets such as compressors, turbines, pumps, and other high-speed rotating equipment.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 330901-05-32-05-02-00 |

| Series | 3300 NSv Proximity Probe |

| Weight | 3 kg |

| Total Length | 0.5 m |

| Mounting Thread | M8 x 1 or 5/16-24 UNF (depending on variant) |

| Operating Temperature | -35 °C to +177 °C |

| Linear Range | 0.25 mm to 2.0 mm |

| Frequency Response | Up to 10 kHz |

| Power Supply (via Driver) | -24 VDC (through Proximitor Sensor) |

Product Applications

-

Shaft vibration monitoring in high-speed turbines and compressors

-

Thrust position measurement in pumps and motors

-

Condition monitoring of gearboxes and rotating machinery

-

Early fault detection in bearings and journal systems

-

Integration with protection systems to prevent catastrophic failures

Product Advantages

-

Compact Design: Narrow side-view construction allows installation in restricted spaces.

-

High Accuracy: Provides stable, linear, and repeatable measurements even under harsh industrial environments.

-

Durability: Resistant to oil, vibration, and temperature extremes, ensuring long-term reliability.

-

System Compatibility: Fully compatible with Bently Nevada 3300 NSv Proximitor Sensors and monitoring systems.

-

Enhanced Safety: Enables predictive maintenance and machinery protection, reducing unexpected downtime.

-

Global Standard: Trusted across industries such as oil & gas, power generation, and heavy machinery manufacturing.

FAQ

Q1: What is the typical linear range of the 3300 NSv Proximity Probe?

A1: The linear range is typically between 0.25 mm and 2.0 mm, depending on installation and calibration.

Q2: Can this probe be used with standard 3300 Proximitor Sensors?

A2: No, it must be paired with the 3300 NSv Proximitor Sensor designed specifically for NSv probes.

Q3: What type of cable does this probe use?

A3: It uses an integral coaxial cable with rugged connectors designed to minimize electrical noise.

Q4: How does the frequency response affect its application?

A4: With a frequency response up to 10 kHz, it is suitable for detecting high-speed shaft vibrations and dynamic movements.

Q5: What kind of machinery benefits most from this probe?

A5: It is best suited for high-speed rotating equipment such as turbines, compressors, pumps, and gear-driven machines.

Q6: Is it resistant to oil contamination in bearing housings?

A6: Yes, the probe is built with robust sealing to operate reliably in oil-lubricated environments.

Q7: How is the probe typically mounted?

A7: It is mounted using threaded sleeves (M8 x 1 or 5/16-24 UNF), ensuring secure and stable installation.

Q8: Can the probe be used for both dynamic and static measurements?

A8: Yes, it accurately measures both vibration (dynamic) and shaft position (static) displacements.

Q9: What is the main difference between NSv probes and standard probes?

A9: NSv probes are narrower, making them ideal for applications where space is limited, without losing accuracy.

Q10: How does temperature affect probe accuracy?

A10: The probe is designed to maintain stability within -35 °C to +177 °C, with minimal thermal drift.

Bently Nevada 330901-05-32-05-02-00 3300 NSv Proximity Probe

Manufacturer:Bently Nevada

Product Number:330901-05-32-05-02-00

Product Type:3300 NSv Proximity Probe

Origin:USA

Total Length:0.5 m

Weight :3 kg

Views:49

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330901-05-32-05-02-00, 3300 NSv Proximity Probe is a highly reliable transducer used for shaft vibration and position measurements in rotating machinery. It belongs to the 3300 NSv (Narrow Side-view) probe series, which was specifically designed for applications where smaller probe dimensions are required without sacrificing accuracy. This model provides precise measurement of dynamic and static displacements, ensuring accurate monitoring and protection of critical assets such as compressors, turbines, pumps, and other high-speed rotating equipment.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 330901-05-32-05-02-00 |

| Series | 3300 NSv Proximity Probe |

| Weight | 3 kg |

| Total Length | 0.5 m |

| Mounting Thread | M8 x 1 or 5/16-24 UNF (depending on variant) |

| Operating Temperature | -35 °C to +177 °C |

| Linear Range | 0.25 mm to 2.0 mm |

| Frequency Response | Up to 10 kHz |

| Power Supply (via Driver) | -24 VDC (through Proximitor Sensor) |

Product Applications

-

Shaft vibration monitoring in high-speed turbines and compressors

-

Thrust position measurement in pumps and motors

-

Condition monitoring of gearboxes and rotating machinery

-

Early fault detection in bearings and journal systems

-

Integration with protection systems to prevent catastrophic failures

Product Advantages

-

Compact Design: Narrow side-view construction allows installation in restricted spaces.

-

High Accuracy: Provides stable, linear, and repeatable measurements even under harsh industrial environments.

-

Durability: Resistant to oil, vibration, and temperature extremes, ensuring long-term reliability.

-

System Compatibility: Fully compatible with Bently Nevada 3300 NSv Proximitor Sensors and monitoring systems.

-

Enhanced Safety: Enables predictive maintenance and machinery protection, reducing unexpected downtime.

-

Global Standard: Trusted across industries such as oil & gas, power generation, and heavy machinery manufacturing.

FAQ

Q1: What is the typical linear range of the 3300 NSv Proximity Probe?

A1: The linear range is typically between 0.25 mm and 2.0 mm, depending on installation and calibration.

Q2: Can this probe be used with standard 3300 Proximitor Sensors?

A2: No, it must be paired with the 3300 NSv Proximitor Sensor designed specifically for NSv probes.

Q3: What type of cable does this probe use?

A3: It uses an integral coaxial cable with rugged connectors designed to minimize electrical noise.

Q4: How does the frequency response affect its application?

A4: With a frequency response up to 10 kHz, it is suitable for detecting high-speed shaft vibrations and dynamic movements.

Q5: What kind of machinery benefits most from this probe?

A5: It is best suited for high-speed rotating equipment such as turbines, compressors, pumps, and gear-driven machines.

Q6: Is it resistant to oil contamination in bearing housings?

A6: Yes, the probe is built with robust sealing to operate reliably in oil-lubricated environments.

Q7: How is the probe typically mounted?

A7: It is mounted using threaded sleeves (M8 x 1 or 5/16-24 UNF), ensuring secure and stable installation.

Q8: Can the probe be used for both dynamic and static measurements?

A8: Yes, it accurately measures both vibration (dynamic) and shaft position (static) displacements.

Q9: What is the main difference between NSv probes and standard probes?

A9: NSv probes are narrower, making them ideal for applications where space is limited, without losing accuracy.

Q10: How does temperature affect probe accuracy?

A10: The probe is designed to maintain stability within -35 °C to +177 °C, with minimal thermal drift.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...