Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

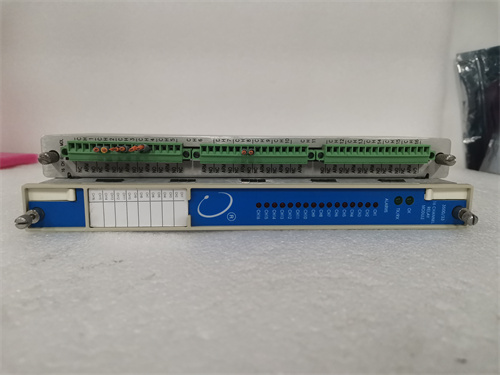

Bently Nevada 330180-X0-00 145004-115 3300 XL 8mm Proximitor Sensor

Manufacturer:Bently Nevada

Product Number:330180-X0-00 145004-115

Product Type:3300 XL 8mm Proximitor Sensor

Origin:USA

Dimensions:81.3 x 35.1 x 58.4 mm

Weight:0.246 kg

Views:32

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330180-X0-00 / 145004-115 – 3300 XL 8mm Proximitor Sensor is a high-precision, non-contact eddy current proximity probe designed to detect the dynamic and static displacement of rotating machinery shafts. As a critical component of the 3300 XL series, this sensor is widely used in condition monitoring and protection systems for critical rotating equipment such as turbines, compressors, motors, and gearboxes.

The 3300 XL 8mm system is engineered to deliver high accuracy, robust environmental resistance, and low signal noise, making it ideal for harsh industrial conditions. When used with a matching extension cable and Proximitor® driver, the system outputs a highly linear voltage signal that represents the shaft’s relative motion and position.

The 145004-115 variant is part of the 330180 probe family, with specific mechanical or connector features designed to meet application-specific installation or regulatory requirements. With its reputation for ruggedness and field-proven performance, this sensor plays a key role in API 670-compliant machinery protection systems.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | 3300 XL 8mm Proximitor Sensor |

| Part Numbers | 330180-X0-00 / 145004-115 |

| Manufacturer | Bently Nevada (a Baker Hughes company) |

| Product Series | 3300 XL Series |

| Sensor Type | Eddy Current Proximity Probe |

| Measurement Range | 0 to 2 mm (0–80 mils) |

| Linear Range | 0.25 mm to 2.0 mm (10–80 mils) |

| Output Sensitivity | -200 mV/mil ±5% (nominal) |

| Calibration Material | AISI 4140 Steel (Standard) |

| Frequency Response | 0 – 10 kHz (typical vibration monitoring) |

| Tip Diameter | 8 mm |

| Mounting Thread Type | 1/4-28 UNF or M8 × 1 (variant dependent) |

| Cable Connector Type | Miniature coaxial (integrated or pigtail) |

| Cable Length Options | 5 m, 7 m, 9 m (system-dependent) |

| Enclosure Rating | IP67, hermetically sealed |

| Operating Temperature Range | -35°C to +177°C (sensor tip) |

| Shock and Vibration Resistance | 50 g peak, 10–2,000 Hz |

| EMI/RFI Immunity | High (double-shielded triaxial cable) |

| Certifications | CE, ATEX, CSA (depending on model configuration) |

| Dimensions (L × D) | 81.3 x 35.1 x 58.4 mm |

| Weight | 0.246 kg |

Product Applications

The 330180-X0-00 / 145004-115 8mm Proximitor Sensor is utilized in high-value rotating machinery where real-time monitoring of shaft movement, vibration, and positioning is critical for operational safety and performance optimization. Key application areas include:

-

Steam and Gas Turbines

For measuring rotor shaft axial position and dynamic vibration to prevent rubs or imbalance.

-

Centrifugal and Reciprocating Compressors

Used for rod drop, shaft orbit, and phase reference monitoring.

-

Large AC/DC Motors and Generators

Installed to track bearing wear, shaft alignment, and looseness.

-

Petrochemical Pumps and API Machinery

Enables machinery to comply with API 670 protection system requirements.

-

Industrial Fans, Blowers, and Gear Drives

Provides feedback for real-time monitoring, predictive maintenance, and shutdown protection.

-

Power Plants and Refinery Critical Equipment

Integrated into safety and control systems for continuous, 24/7 monitoring.

Product Advantages

-

High Signal Accuracy and Stability

Delivers precise measurements with minimal drift or temperature influence over time.

-

Field-Proven Reliability

Thousands of installations worldwide demonstrate robust performance in demanding environments.

-

Rugged, Hermetically Sealed Construction

Fully sealed against dust, oil, moisture, and chemical exposure—ideal for harsh industrial zones.

-

Flexible System Compatibility

Easily integrates with 3300 XL Proximitor modules and other Bently Nevada systems.

-

Extended Temperature Range

Operates safely at up to +177°C at the probe tip, suitable for high-heat applications.

-

EMI/RFI Shielded Cabling

Ensures signal integrity in electrically noisy environments such as substations or near high-voltage equipment.

-

API 670 Compliance

Designed to meet or exceed the standards for shaft vibration and position measurement in critical rotating equipment.

-

Minimal Maintenance Required

Long operational lifespan with low maintenance frequency, reducing system downtime and service costs.

-

Customizable Lengths and Mounting Threads

Supports a variety of configurations to suit different machinery and space constraints.

-

Designed for Predictive Maintenance Systems

Enables early detection of equipment faults, reducing unplanned outages and repair costs.

FAQ

-

What type of signal does the 330180-X0-00 output?

The probe system outputs an analog voltage signal of -200 mV/mil for shaft displacement measurement.

-

What Proximitor modules are compatible with this probe?

It is designed to work with 3300 XL Proximitor modules of matching system length and configuration.

-

Is this probe suitable for axial and radial position measurement?

Yes, it can be mounted for both axial thrust and radial vibration monitoring.

-

How is calibration handled for different materials?

Standard calibration is for AISI 4140 steel; other materials require a material conversion factor.

-

Can this sensor be used in hazardous zones?

Yes, when used with appropriately certified system components, it is ATEX and CSA compliant.

-

Does this sensor require grounding?

Grounding is handled through the shield of the triaxial cable and the Proximitor driver system.

-

What’s the minimum bend radius of the sensor cable?

Typically, 25 mm minimum bend radius is recommended to maintain cable integrity.

-

What kind of vibration resistance does this sensor have?

It withstands 50 g shock and vibration in the 10–2,000 Hz range, suitable for turbine applications.

-

Can it be installed near high voltage equipment?

Yes, it features high EMI immunity, making it suitable for high-voltage or electrically noisy environments.

-

How is the system length defined and why is it important?

System length is the combined length of the probe and extension cable; it must match the Proximitor module for correct calibration and linearity.

Bently Nevada 330180-X0-00 145004-115 3300 XL 8mm Proximitor Sensor

Manufacturer:Bently Nevada

Product Number:330180-X0-00 145004-115

Product Type:3300 XL 8mm Proximitor Sensor

Origin:USA

Dimensions:81.3 x 35.1 x 58.4 mm

Weight:0.246 kg

Views:32

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330180-X0-00 / 145004-115 – 3300 XL 8mm Proximitor Sensor is a high-precision, non-contact eddy current proximity probe designed to detect the dynamic and static displacement of rotating machinery shafts. As a critical component of the 3300 XL series, this sensor is widely used in condition monitoring and protection systems for critical rotating equipment such as turbines, compressors, motors, and gearboxes.

The 3300 XL 8mm system is engineered to deliver high accuracy, robust environmental resistance, and low signal noise, making it ideal for harsh industrial conditions. When used with a matching extension cable and Proximitor® driver, the system outputs a highly linear voltage signal that represents the shaft’s relative motion and position.

The 145004-115 variant is part of the 330180 probe family, with specific mechanical or connector features designed to meet application-specific installation or regulatory requirements. With its reputation for ruggedness and field-proven performance, this sensor plays a key role in API 670-compliant machinery protection systems.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | 3300 XL 8mm Proximitor Sensor |

| Part Numbers | 330180-X0-00 / 145004-115 |

| Manufacturer | Bently Nevada (a Baker Hughes company) |

| Product Series | 3300 XL Series |

| Sensor Type | Eddy Current Proximity Probe |

| Measurement Range | 0 to 2 mm (0–80 mils) |

| Linear Range | 0.25 mm to 2.0 mm (10–80 mils) |

| Output Sensitivity | -200 mV/mil ±5% (nominal) |

| Calibration Material | AISI 4140 Steel (Standard) |

| Frequency Response | 0 – 10 kHz (typical vibration monitoring) |

| Tip Diameter | 8 mm |

| Mounting Thread Type | 1/4-28 UNF or M8 × 1 (variant dependent) |

| Cable Connector Type | Miniature coaxial (integrated or pigtail) |

| Cable Length Options | 5 m, 7 m, 9 m (system-dependent) |

| Enclosure Rating | IP67, hermetically sealed |

| Operating Temperature Range | -35°C to +177°C (sensor tip) |

| Shock and Vibration Resistance | 50 g peak, 10–2,000 Hz |

| EMI/RFI Immunity | High (double-shielded triaxial cable) |

| Certifications | CE, ATEX, CSA (depending on model configuration) |

| Dimensions (L × D) | 81.3 x 35.1 x 58.4 mm |

| Weight | 0.246 kg |

Product Applications

The 330180-X0-00 / 145004-115 8mm Proximitor Sensor is utilized in high-value rotating machinery where real-time monitoring of shaft movement, vibration, and positioning is critical for operational safety and performance optimization. Key application areas include:

-

Steam and Gas Turbines

For measuring rotor shaft axial position and dynamic vibration to prevent rubs or imbalance.

-

Centrifugal and Reciprocating Compressors

Used for rod drop, shaft orbit, and phase reference monitoring.

-

Large AC/DC Motors and Generators

Installed to track bearing wear, shaft alignment, and looseness.

-

Petrochemical Pumps and API Machinery

Enables machinery to comply with API 670 protection system requirements.

-

Industrial Fans, Blowers, and Gear Drives

Provides feedback for real-time monitoring, predictive maintenance, and shutdown protection.

-

Power Plants and Refinery Critical Equipment

Integrated into safety and control systems for continuous, 24/7 monitoring.

Product Advantages

-

High Signal Accuracy and Stability

Delivers precise measurements with minimal drift or temperature influence over time.

-

Field-Proven Reliability

Thousands of installations worldwide demonstrate robust performance in demanding environments.

-

Rugged, Hermetically Sealed Construction

Fully sealed against dust, oil, moisture, and chemical exposure—ideal for harsh industrial zones.

-

Flexible System Compatibility

Easily integrates with 3300 XL Proximitor modules and other Bently Nevada systems.

-

Extended Temperature Range

Operates safely at up to +177°C at the probe tip, suitable for high-heat applications.

-

EMI/RFI Shielded Cabling

Ensures signal integrity in electrically noisy environments such as substations or near high-voltage equipment.

-

API 670 Compliance

Designed to meet or exceed the standards for shaft vibration and position measurement in critical rotating equipment.

-

Minimal Maintenance Required

Long operational lifespan with low maintenance frequency, reducing system downtime and service costs.

-

Customizable Lengths and Mounting Threads

Supports a variety of configurations to suit different machinery and space constraints.

-

Designed for Predictive Maintenance Systems

Enables early detection of equipment faults, reducing unplanned outages and repair costs.

FAQ

-

What type of signal does the 330180-X0-00 output?

The probe system outputs an analog voltage signal of -200 mV/mil for shaft displacement measurement.

-

What Proximitor modules are compatible with this probe?

It is designed to work with 3300 XL Proximitor modules of matching system length and configuration.

-

Is this probe suitable for axial and radial position measurement?

Yes, it can be mounted for both axial thrust and radial vibration monitoring.

-

How is calibration handled for different materials?

Standard calibration is for AISI 4140 steel; other materials require a material conversion factor.

-

Can this sensor be used in hazardous zones?

Yes, when used with appropriately certified system components, it is ATEX and CSA compliant.

-

Does this sensor require grounding?

Grounding is handled through the shield of the triaxial cable and the Proximitor driver system.

-

What’s the minimum bend radius of the sensor cable?

Typically, 25 mm minimum bend radius is recommended to maintain cable integrity.

-

What kind of vibration resistance does this sensor have?

It withstands 50 g shock and vibration in the 10–2,000 Hz range, suitable for turbine applications.

-

Can it be installed near high voltage equipment?

Yes, it features high EMI immunity, making it suitable for high-voltage or electrically noisy environments.

-

How is the system length defined and why is it important?

System length is the combined length of the probe and extension cable; it must match the Proximitor module for correct calibration and linearity.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...