Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

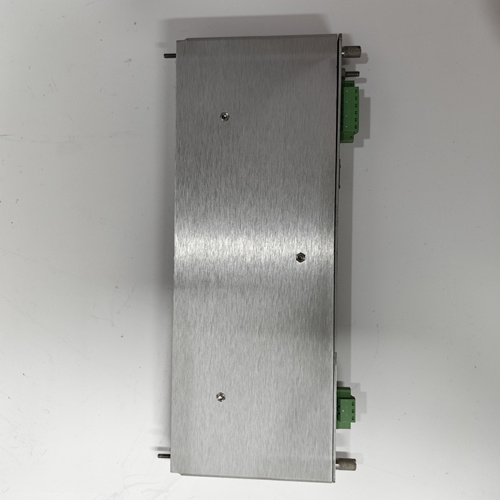

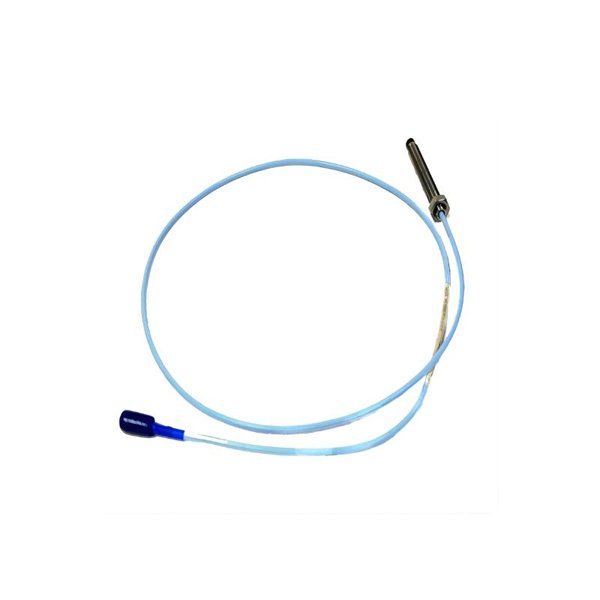

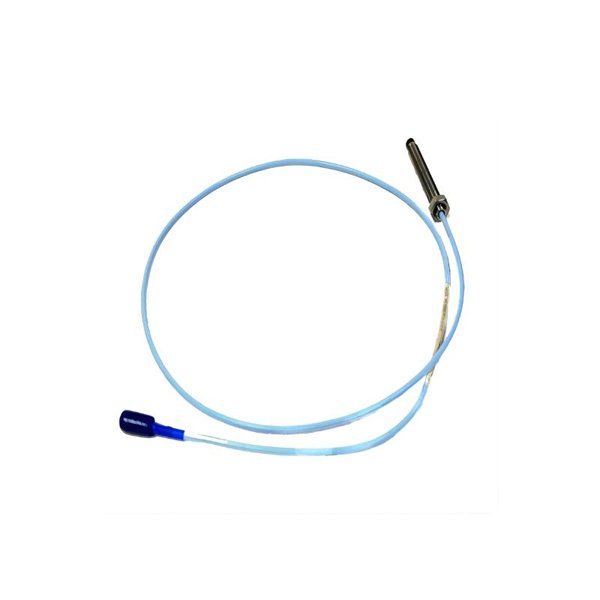

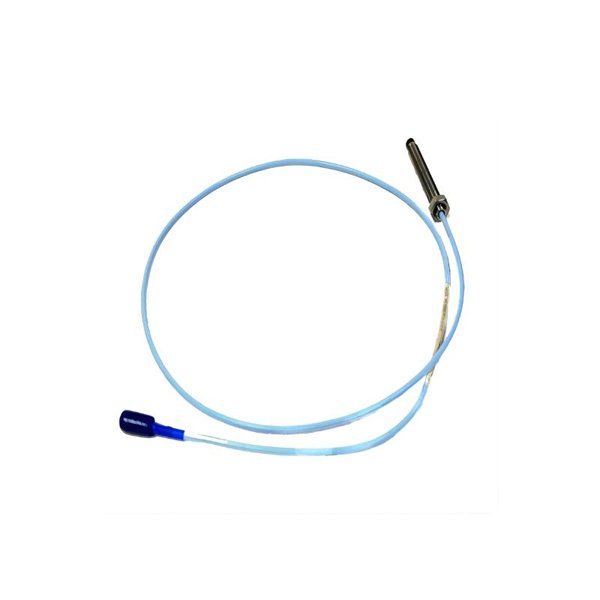

Bently Nevada 330102-00-40-05-02-00 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330102-00-40-05-02-00

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:0.5 m

Weight :0.162 kg

Views:32

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330102-00-40-05-02-00 (3300 XL 8 mm Proximity Probe) is a precision displacement sensor designed for critical machinery monitoring applications. It forms part of the 3300 XL series, a widely trusted family of probes, extension cables, and proximitor sensors used in turbine and compressor protection systems across industries.

This proximity probe is capable of providing accurate non-contact measurement of shaft vibration and position relative to the probe tip, using eddy current technology. The 3300 XL series is known for its robust design, compliance with stringent API 670 standards, and ability to withstand harsh industrial conditions.

The probe, when paired with its matching extension cable and proximitor, ensures linear, reliable output for both static and dynamic measurements. This makes it essential in predictive maintenance, preventing machinery failures and ensuring safe, efficient operation.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | 330102-00-40-05-02-00 |

| Series | 3300 XL 8 mm Proximity Probe |

| Sensing Principle | Eddy current, non-contact measurement |

| Linear Range | 2 mm (80 mils) |

| Sensitivity | 7.87 V/mm (200 mV/mil) |

| Frequency Response | DC to 10 kHz |

| Gap Voltage Range | –2 V to –18 V |

| Operating Temperature | –35 °C to +177 °C |

| Probe Tip Diameter | 8 mm |

| Thread Size | M10 × 1 or 3/8-24 UNF (depending on variant) |

| Total Length | 0.5 m |

| Weight | 0.162 kg |

| Material | Stainless steel body, hermetically sealed |

| Compatibility | Works with 3300 XL Extension Cables and 3300 XL Proximitor Sensors |

Product Applications

The 3300 XL 8 mm Proximity Probe is primarily used in rotating machinery monitoring. Key applications include:

-

Shaft vibration monitoring in turbines, compressors, and pumps.

-

Thrust position measurement in large steam and gas turbines.

-

Rotor dynamic analysis for predictive maintenance programs.

-

Integration into condition monitoring and protection systems.

-

Continuous monitoring in power generation, petrochemical, and refinery environments.

-

Compliance with API 670 for critical machinery protection.

Product Advantages

-

High Accuracy: Provides precise shaft vibration and displacement measurement, reducing false alarms.

-

Wide Temperature Capability: Designed to operate in extreme industrial environments up to +177 °C.

-

API 670 Compliance: Meets global standards for machinery protection systems.

-

Robust Construction: Stainless steel housing ensures durability in corrosive and high-vibration conditions.

-

Interchangeability: Fully compatible with other 3300 XL probes, cables, and proximitor sensors without calibration mismatch.

-

Reliable Long-Term Stability: Proven track record in critical industries such as power plants, oil & gas, and heavy manufacturing.

FAQ

Q1: How does the 3300 XL 8 mm probe achieve non-contact measurement?

A1: It uses eddy current technology, where an electromagnetic field interacts with the conductive shaft surface, allowing displacement measurement without physical contact.

Q2: What is the maximum frequency response of this probe?

A2: The probe provides accurate response from DC up to 10 kHz, which covers most critical machinery vibration frequencies.

Q3: Can this probe be used for thrust position monitoring?

A3: Yes, it is widely used for both radial vibration and thrust position monitoring in turbines and compressors.

Q4: How is the sensitivity of the probe defined?

A4: Sensitivity is 200 mV/mil (7.87 V/mm), which ensures a linear voltage output proportional to shaft movement.

Q5: What type of proximitor is compatible with this probe?

A5: It is compatible with the Bently Nevada 3300 XL Proximitor Sensor, specifically designed to match its electrical characteristics.

Q6: How does the probe maintain performance in high temperature environments?

A6: Its materials and internal design allow continuous operation at temperatures up to +177 °C without degradation.

Q7: Is calibration required when replacing a probe?

A7: No, the 3300 XL probes are designed to be interchangeable, ensuring consistent performance without recalibration.

Q8: Can the probe detect both static and dynamic signals?

A8: Yes, it can measure static shaft position and dynamic vibration signals simultaneously.

Q9: What is the typical gap voltage range for installation?

A9: The operating gap voltage is between –2 V and –18 V, ensuring correct linear range performance.

Q10: How does cable length affect probe performance?

A10: The probe, extension cable, and proximitor are a matched system; cable length must match the system specification to maintain accuracy.

Bently Nevada 330102-00-40-05-02-00 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330102-00-40-05-02-00

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:0.5 m

Weight :0.162 kg

Views:32

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330102-00-40-05-02-00 (3300 XL 8 mm Proximity Probe) is a precision displacement sensor designed for critical machinery monitoring applications. It forms part of the 3300 XL series, a widely trusted family of probes, extension cables, and proximitor sensors used in turbine and compressor protection systems across industries.

This proximity probe is capable of providing accurate non-contact measurement of shaft vibration and position relative to the probe tip, using eddy current technology. The 3300 XL series is known for its robust design, compliance with stringent API 670 standards, and ability to withstand harsh industrial conditions.

The probe, when paired with its matching extension cable and proximitor, ensures linear, reliable output for both static and dynamic measurements. This makes it essential in predictive maintenance, preventing machinery failures and ensuring safe, efficient operation.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | 330102-00-40-05-02-00 |

| Series | 3300 XL 8 mm Proximity Probe |

| Sensing Principle | Eddy current, non-contact measurement |

| Linear Range | 2 mm (80 mils) |

| Sensitivity | 7.87 V/mm (200 mV/mil) |

| Frequency Response | DC to 10 kHz |

| Gap Voltage Range | –2 V to –18 V |

| Operating Temperature | –35 °C to +177 °C |

| Probe Tip Diameter | 8 mm |

| Thread Size | M10 × 1 or 3/8-24 UNF (depending on variant) |

| Total Length | 0.5 m |

| Weight | 0.162 kg |

| Material | Stainless steel body, hermetically sealed |

| Compatibility | Works with 3300 XL Extension Cables and 3300 XL Proximitor Sensors |

Product Applications

The 3300 XL 8 mm Proximity Probe is primarily used in rotating machinery monitoring. Key applications include:

-

Shaft vibration monitoring in turbines, compressors, and pumps.

-

Thrust position measurement in large steam and gas turbines.

-

Rotor dynamic analysis for predictive maintenance programs.

-

Integration into condition monitoring and protection systems.

-

Continuous monitoring in power generation, petrochemical, and refinery environments.

-

Compliance with API 670 for critical machinery protection.

Product Advantages

-

High Accuracy: Provides precise shaft vibration and displacement measurement, reducing false alarms.

-

Wide Temperature Capability: Designed to operate in extreme industrial environments up to +177 °C.

-

API 670 Compliance: Meets global standards for machinery protection systems.

-

Robust Construction: Stainless steel housing ensures durability in corrosive and high-vibration conditions.

-

Interchangeability: Fully compatible with other 3300 XL probes, cables, and proximitor sensors without calibration mismatch.

-

Reliable Long-Term Stability: Proven track record in critical industries such as power plants, oil & gas, and heavy manufacturing.

FAQ

Q1: How does the 3300 XL 8 mm probe achieve non-contact measurement?

A1: It uses eddy current technology, where an electromagnetic field interacts with the conductive shaft surface, allowing displacement measurement without physical contact.

Q2: What is the maximum frequency response of this probe?

A2: The probe provides accurate response from DC up to 10 kHz, which covers most critical machinery vibration frequencies.

Q3: Can this probe be used for thrust position monitoring?

A3: Yes, it is widely used for both radial vibration and thrust position monitoring in turbines and compressors.

Q4: How is the sensitivity of the probe defined?

A4: Sensitivity is 200 mV/mil (7.87 V/mm), which ensures a linear voltage output proportional to shaft movement.

Q5: What type of proximitor is compatible with this probe?

A5: It is compatible with the Bently Nevada 3300 XL Proximitor Sensor, specifically designed to match its electrical characteristics.

Q6: How does the probe maintain performance in high temperature environments?

A6: Its materials and internal design allow continuous operation at temperatures up to +177 °C without degradation.

Q7: Is calibration required when replacing a probe?

A7: No, the 3300 XL probes are designed to be interchangeable, ensuring consistent performance without recalibration.

Q8: Can the probe detect both static and dynamic signals?

A8: Yes, it can measure static shaft position and dynamic vibration signals simultaneously.

Q9: What is the typical gap voltage range for installation?

A9: The operating gap voltage is between –2 V and –18 V, ensuring correct linear range performance.

Q10: How does cable length affect probe performance?

A10: The probe, extension cable, and proximitor are a matched system; cable length must match the system specification to maintain accuracy.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...