Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

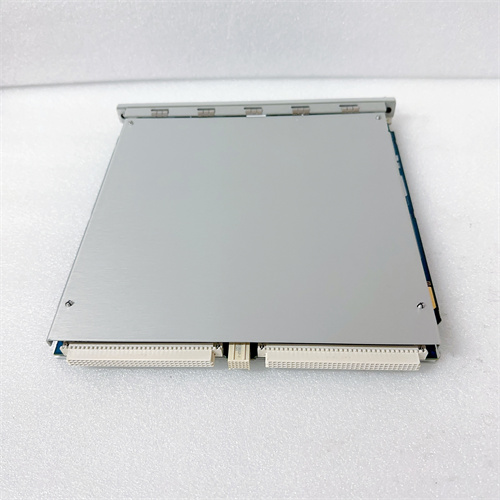

Bently Nevada 330980-71-05 3300 XL NSv Front Sensor

Manufacturer:Bently Nevada

Product Number:330980-71-05

Product Type:3300 XL NSv Front Sensor

Origin:USA

Dimensions:Total Length: 7.0 meters

Weight:0.255kg

Views:47

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330980-71-05 3300 XL NSv Rear Sensor is a non-contact eddy current proximity probe designed for small or confined machinery spaces where standard probes cannot fit. As part of the 3300 XL NSv (Narrow Side-view) system, the Rear Sensor allows measurements from the rear access point of a machine, providing highly accurate shaft vibration and position monitoring.

Key Features

-

Narrow side-view (NSv) Rear Sensor for limited access installations

-

High sensitivity: 7.87 V/mm (200 mV/mil)

-

Compatible with 3300 NSv Proximitor Sensors

-

CE, CSA, and UL certifications for hazardous locations

-

Robust construction for extreme temperatures and vibration

-

Factory-calibrated for consistent accuracy

Technical Specifications

| Item | Specification |

|---|---|

| Model Number | 330980-71-05 |

| Type | 3300 XL NSv Rear Sensor |

| Measurement Principle | Non-contact eddy current proximity probe |

| Target Material | Conductive (typically 4140 steel or equivalent) |

| Sensitivity | 7.87 V/mm (200 mV/mil) |

| Linear Range | 0.25 mm to 2.0 mm (10 to 80 mils) |

| Probe Tip Diameter | 5 mm (NSv design) |

| Probe Length | Rear Sensor configuration |

| Operating Temperature | -35 °C to +177 °C |

| Storage Temperature | -40 °C to +177 °C |

| Pressure Rating | Up to 500 kPa (72 psi) |

| Compatible Proximitor | 3300 NSv Proximitor Sensor |

| Compliance | CE, CSA, UL for hazardous areas |

| Dimensions | Total Length: 7.0 meters |

| Weight | 0.255 kg |

Industry Applications

-

Power Generation – steam, gas, and hydro turbines

-

Petrochemical Plants – rotating machinery in refineries and chemical plants

-

Pulp & Paper – critical pumps and process motors

-

Mining & Metals – heavy-duty rotating equipment

-

Marine & Offshore – propulsion systems and auxiliary rotating equipment

Advantages

-

Rear access configuration – ideal for machines with limited front access

-

Compact NSv design – fits in tight spaces without compromising accuracy

-

High accuracy and reliability – ensures precise long-term monitoring

-

Harsh environment resistance – suitable for extreme temperatures and vibrations

-

Certified for hazardous areas – CE, CSA, UL compliance

-

Seamless integration – works with 3300 NSv Proximitor Sensors and 3500 series monitors

Frequently Asked Questions (FAQ)

Q1: What is the main difference between the 330980-71-05 and 330980-70-05?

The 71-05 is a Rear Sensor for rear-access installation, while the 70-05 is a Front Sensor for front-access mounting.

Q2: What is the sensitivity of the Rear Sensor?

It is 7.87 V/mm (200 mV/mil).

Q3: What is the linear measurement range?

0.25 mm to 2.0 mm (10 to 80 mils).

Q4: What is the operating temperature range?

-35 °C to +177 °C.

Q5: Is it compatible with standard Bently Nevada monitoring systems?

Yes, it works with 3300 NSv Proximitor Sensors and integrates with 3500 series monitors.

Q6: Can it be used in hazardous areas?

Yes, it has CE, CSA, and UL certifications.

Q7: What is the probe diameter and length?

5 mm diameter × 32 mm length.

Q8: What industries typically use this sensor?

Oil & Gas, Power Generation, Petrochemical, Pulp & Paper, Mining, and Marine applications.

Q9: How is it mounted?

Using threaded installation in bearing housings or designated rear-access points.

Q10: Why choose the Rear Sensor over the Front Sensor?

It enables monitoring in machines where front access is limited or obstructed, maintaining precise vibration measurement.

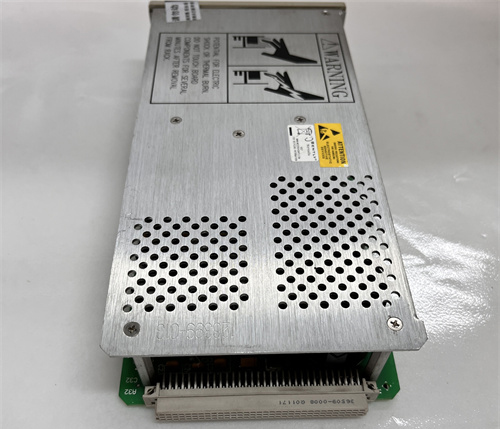

Bently Nevada 330980-71-05 3300 XL NSv Front Sensor

Manufacturer:Bently Nevada

Product Number:330980-71-05

Product Type:3300 XL NSv Front Sensor

Origin:USA

Dimensions:Total Length: 7.0 meters

Weight:0.255kg

Views:47

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330980-71-05 3300 XL NSv Rear Sensor is a non-contact eddy current proximity probe designed for small or confined machinery spaces where standard probes cannot fit. As part of the 3300 XL NSv (Narrow Side-view) system, the Rear Sensor allows measurements from the rear access point of a machine, providing highly accurate shaft vibration and position monitoring.

Key Features

-

Narrow side-view (NSv) Rear Sensor for limited access installations

-

High sensitivity: 7.87 V/mm (200 mV/mil)

-

Compatible with 3300 NSv Proximitor Sensors

-

CE, CSA, and UL certifications for hazardous locations

-

Robust construction for extreme temperatures and vibration

-

Factory-calibrated for consistent accuracy

Technical Specifications

| Item | Specification |

|---|---|

| Model Number | 330980-71-05 |

| Type | 3300 XL NSv Rear Sensor |

| Measurement Principle | Non-contact eddy current proximity probe |

| Target Material | Conductive (typically 4140 steel or equivalent) |

| Sensitivity | 7.87 V/mm (200 mV/mil) |

| Linear Range | 0.25 mm to 2.0 mm (10 to 80 mils) |

| Probe Tip Diameter | 5 mm (NSv design) |

| Probe Length | Rear Sensor configuration |

| Operating Temperature | -35 °C to +177 °C |

| Storage Temperature | -40 °C to +177 °C |

| Pressure Rating | Up to 500 kPa (72 psi) |

| Compatible Proximitor | 3300 NSv Proximitor Sensor |

| Compliance | CE, CSA, UL for hazardous areas |

| Dimensions | Total Length: 7.0 meters |

| Weight | 0.255 kg |

Industry Applications

-

Power Generation – steam, gas, and hydro turbines

-

Petrochemical Plants – rotating machinery in refineries and chemical plants

-

Pulp & Paper – critical pumps and process motors

-

Mining & Metals – heavy-duty rotating equipment

-

Marine & Offshore – propulsion systems and auxiliary rotating equipment

Advantages

-

Rear access configuration – ideal for machines with limited front access

-

Compact NSv design – fits in tight spaces without compromising accuracy

-

High accuracy and reliability – ensures precise long-term monitoring

-

Harsh environment resistance – suitable for extreme temperatures and vibrations

-

Certified for hazardous areas – CE, CSA, UL compliance

-

Seamless integration – works with 3300 NSv Proximitor Sensors and 3500 series monitors

Frequently Asked Questions (FAQ)

Q1: What is the main difference between the 330980-71-05 and 330980-70-05?

The 71-05 is a Rear Sensor for rear-access installation, while the 70-05 is a Front Sensor for front-access mounting.

Q2: What is the sensitivity of the Rear Sensor?

It is 7.87 V/mm (200 mV/mil).

Q3: What is the linear measurement range?

0.25 mm to 2.0 mm (10 to 80 mils).

Q4: What is the operating temperature range?

-35 °C to +177 °C.

Q5: Is it compatible with standard Bently Nevada monitoring systems?

Yes, it works with 3300 NSv Proximitor Sensors and integrates with 3500 series monitors.

Q6: Can it be used in hazardous areas?

Yes, it has CE, CSA, and UL certifications.

Q7: What is the probe diameter and length?

5 mm diameter × 32 mm length.

Q8: What industries typically use this sensor?

Oil & Gas, Power Generation, Petrochemical, Pulp & Paper, Mining, and Marine applications.

Q9: How is it mounted?

Using threaded installation in bearing housings or designated rear-access points.

Q10: Why choose the Rear Sensor over the Front Sensor?

It enables monitoring in machines where front access is limited or obstructed, maintaining precise vibration measurement.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...