Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

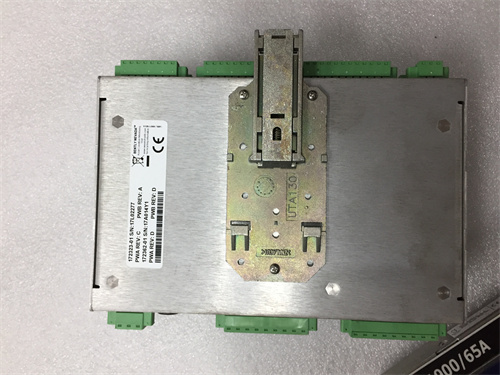

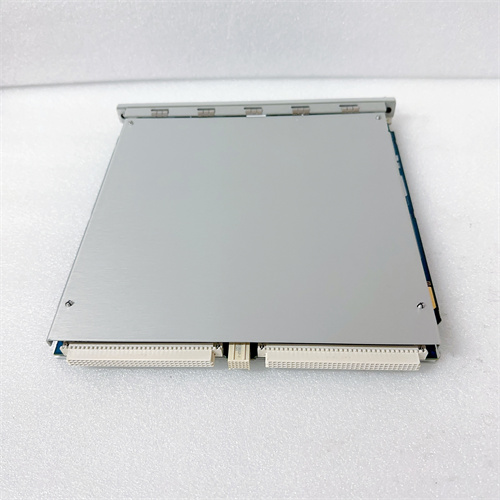

Bently Nevada 3300/16-02-01-00-01-00-00 Dual Vibration Monitor

Brand:Bently Nevada

Model Number:3300/16-02-01-00-01-00-00

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:5.7 cm x 20.3 cm x 33.0 cm

Weight:1.1 kg

Price:USD59

Certificate:CE

Warranty:1 years

Product Description

The Bently Nevada 3300/16-02-01-00-01-00-00 is a dual vibration monitor. It continuously measures and monitors two independent channels of radial vibration. Additionally, it tracks average shaft position (gap). The device accepts inputs from two proximity probe/Proximitor® systems. It is widely used in industrial machinery and rotating equipment for condition monitoring and fault detection.

Key Features and Benefits

- Dual Vibration Monitoring: Measures and monitors two independent channels of radial vibration simultaneously.

- Shaft Position Monitoring: Continuously tracks average shaft position (gap).

- Proximity Probe Compatibility: Accepts inputs from two proximity probes or Proximitors.

- Reliable Performance: Designed for harsh industrial environments; ensures accurate and reliable measurements.

- Condition Monitoring: Detects potential equipment failures early, reducing downtime and maintenance costs.

Technical Specifications

- Channels: 2 independent vibration channels

- Inputs: 2 proximity probe/Proximitor® inputs

- Measurements: Radial vibration, shaft position (gap)

- Outputs: Analog and digital outputs for system integration

Applications

Bently Nevada 3300/16-02-01-00-01-00-00 Dual Vibration Monitor

Brand:Bently Nevada

Model Number:3300/16-02-01-00-01-00-00

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:5.7 cm x 20.3 cm x 33.0 cm

Weight:1.1 kg

Price:USD59

Certificate:CE

Warranty:1 years

Product Description

The Bently Nevada 3300/16-02-01-00-01-00-00 is a dual vibration monitor. It continuously measures and monitors two independent channels of radial vibration. Additionally, it tracks average shaft position (gap). The device accepts inputs from two proximity probe/Proximitor® systems. It is widely used in industrial machinery and rotating equipment for condition monitoring and fault detection.

Key Features and Benefits

- Dual Vibration Monitoring: Measures and monitors two independent channels of radial vibration simultaneously.

- Shaft Position Monitoring: Continuously tracks average shaft position (gap).

- Proximity Probe Compatibility: Accepts inputs from two proximity probes or Proximitors.

- Reliable Performance: Designed for harsh industrial environments; ensures accurate and reliable measurements.

- Condition Monitoring: Detects potential equipment failures early, reducing downtime and maintenance costs.

Technical Specifications

- Channels: 2 independent vibration channels

- Inputs: 2 proximity probe/Proximitor® inputs

- Measurements: Radial vibration, shaft position (gap)

- Outputs: Analog and digital outputs for system integration

Applications

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...