Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

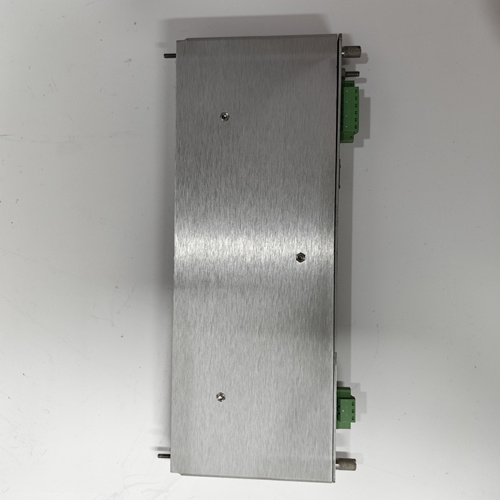

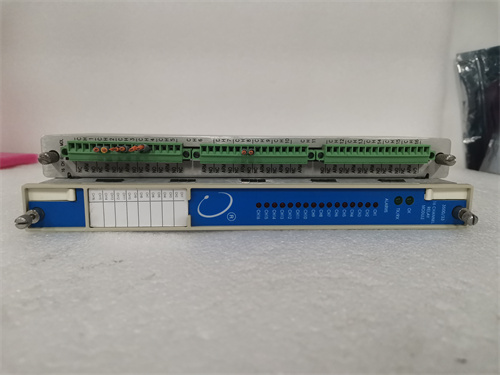

Bently Nevada 330730-080-00-00 3300 XL 11 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330730-080-00-00

Condition:3300 XL 11 mm Proximity Probe

Origin:USA

Cable length:8 m

Weight:0.36 kg

Views:55

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330730 080 00 00 is a part of the renowned Bently Nevada product line, specifically designed for the purpose of advanced machinery condition monitoring. This device is part of the 3300 series, which is widely used for high-performance vibration and condition monitoring in industrial environments. Known for its rugged design and precision, this unit offers real-time monitoring, diagnostics, and protection for machinery, making it essential in industries such as power generation, oil & gas, and manufacturing.

The 330730 080 00 00 system works with Bently Nevada’s vibration transducers and offers excellent compatibility with various monitoring systems. By employing advanced algorithms, it is capable of identifying machinery faults early, thus preventing unplanned downtime and reducing maintenance costs.

Technical Specifications

| Specification | Details |

|---|---|

| Model Number | 330730 080 00 00 |

| Type | Vibration Monitoring System |

| Cable length | 8 m |

| Weight | 0.36 kg |

| Power Supply | 24 VDC |

| Input Channels | 4 Analog Inputs (for transducers) |

| Output Type | Analog Output, Digital Output |

| Environmental Range | -20°C to 60°C |

| Communication Protocol | Modbus RTU, Profibus DP |

| Compliance | CE Certified, UL Listed |

Applications

-

Industrial Equipment Monitoring: The 330730 080 00 00 is designed to be installed on rotating machinery such as motors, turbines, compressors, and pumps for continuous monitoring.

-

Vibration Analysis: Used in environments where precise vibration measurement is required to predict mechanical failures, ensuring the machinery operates within safe limits.

-

Condition Monitoring Systems (CMS): Typically installed as part of a comprehensive condition monitoring system in industries like oil and gas, power generation, mining, and manufacturing.

-

Predictive Maintenance: It helps in identifying abnormal vibration patterns, providing early warnings about possible failures, and thus enabling predictive maintenance.

Advantages

-

Real-Time Monitoring: Provides real-time data for machine health, which helps in detecting issues like imbalance, misalignment, and bearing wear before they cause failure.

-

Durability: Built with rugged materials and designed to withstand harsh industrial environments, ensuring longevity and reliability.

-

Advanced Diagnostics: Offers a variety of diagnostics, including high-speed data logging and advanced signal processing, to enhance predictive maintenance.

-

Ease of Integration: Can be easily integrated into existing monitoring systems, making it a versatile choice for many industrial applications.

-

Reduced Downtime: Helps minimize unplanned downtime and extend the lifespan of machinery, significantly reducing maintenance costs.

-

Flexible Communication Protocols: Supports multiple communication protocols, including Modbus and Profibus, for seamless integration into different systems.

-

Cost-Effective: With early fault detection, the system reduces the need for expensive emergency repairs, making it a cost-effective investment in the long run.

FAQs

Q1: What is the function of the Bently Nevada 330730 080 00 00?

A1: This model is used for monitoring vibrations in machinery to detect issues such as imbalances, misalignment, and bearing wear. It helps prevent mechanical failure by providing early warning signs.

Q2: Is the Bently Nevada 330730 080 00 00 suitable for harsh environments?

A2: Yes, the device is designed to operate in harsh industrial environments and has been built to withstand extreme temperatures and rugged conditions.

Q3: How does the Bently Nevada 330730 080 00 00 communicate with other systems?

A3: It supports Modbus RTU and Profibus DP communication protocols, allowing for easy integration with other monitoring and control systems.

Q4: What are the power requirements for the Bently Nevada 330730 080 00 00?

A4: It operates with a 24 VDC power supply.

Q5: How many input channels does the 330730 080 00 00 support?

A5: This model supports 4 analog input channels for connecting vibration transducers.

Q6: Can the system detect specific machine faults?

A6: Yes, the system is capable of detecting specific faults such as imbalances, misalignments, and bearing wear through advanced signal processing techniques.

Q7: How is the data from the 330730 080 00 00 stored?

A7: The data is typically stored in a connected monitoring system, either locally or remotely, for analysis and historical tracking.

Q8: Does the 330730 080 00 00 provide alarm functions?

A8: Yes, the system can trigger alarms for out-of-range vibration levels or other detected faults, providing early warning for maintenance personnel.

Q9: What industries commonly use the Bently Nevada 330730 080 00 00?

A9: It is widely used in industries such as power generation, oil & gas, manufacturing, and mining for machinery health monitoring.

Q10: Is it easy to install the 330730 080 00 00?

A10: Yes, installation is straightforward, and the unit is designed for ease of integration into existing monitoring setups.

Bently Nevada 330730-080-00-00 3300 XL 11 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330730-080-00-00

Condition:3300 XL 11 mm Proximity Probe

Origin:USA

Cable length:8 m

Weight:0.36 kg

Views:55

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330730 080 00 00 is a part of the renowned Bently Nevada product line, specifically designed for the purpose of advanced machinery condition monitoring. This device is part of the 3300 series, which is widely used for high-performance vibration and condition monitoring in industrial environments. Known for its rugged design and precision, this unit offers real-time monitoring, diagnostics, and protection for machinery, making it essential in industries such as power generation, oil & gas, and manufacturing.

The 330730 080 00 00 system works with Bently Nevada’s vibration transducers and offers excellent compatibility with various monitoring systems. By employing advanced algorithms, it is capable of identifying machinery faults early, thus preventing unplanned downtime and reducing maintenance costs.

Technical Specifications

| Specification | Details |

|---|---|

| Model Number | 330730 080 00 00 |

| Type | Vibration Monitoring System |

| Cable length | 8 m |

| Weight | 0.36 kg |

| Power Supply | 24 VDC |

| Input Channels | 4 Analog Inputs (for transducers) |

| Output Type | Analog Output, Digital Output |

| Environmental Range | -20°C to 60°C |

| Communication Protocol | Modbus RTU, Profibus DP |

| Compliance | CE Certified, UL Listed |

Applications

-

Industrial Equipment Monitoring: The 330730 080 00 00 is designed to be installed on rotating machinery such as motors, turbines, compressors, and pumps for continuous monitoring.

-

Vibration Analysis: Used in environments where precise vibration measurement is required to predict mechanical failures, ensuring the machinery operates within safe limits.

-

Condition Monitoring Systems (CMS): Typically installed as part of a comprehensive condition monitoring system in industries like oil and gas, power generation, mining, and manufacturing.

-

Predictive Maintenance: It helps in identifying abnormal vibration patterns, providing early warnings about possible failures, and thus enabling predictive maintenance.

Advantages

-

Real-Time Monitoring: Provides real-time data for machine health, which helps in detecting issues like imbalance, misalignment, and bearing wear before they cause failure.

-

Durability: Built with rugged materials and designed to withstand harsh industrial environments, ensuring longevity and reliability.

-

Advanced Diagnostics: Offers a variety of diagnostics, including high-speed data logging and advanced signal processing, to enhance predictive maintenance.

-

Ease of Integration: Can be easily integrated into existing monitoring systems, making it a versatile choice for many industrial applications.

-

Reduced Downtime: Helps minimize unplanned downtime and extend the lifespan of machinery, significantly reducing maintenance costs.

-

Flexible Communication Protocols: Supports multiple communication protocols, including Modbus and Profibus, for seamless integration into different systems.

-

Cost-Effective: With early fault detection, the system reduces the need for expensive emergency repairs, making it a cost-effective investment in the long run.

FAQs

Q1: What is the function of the Bently Nevada 330730 080 00 00?

A1: This model is used for monitoring vibrations in machinery to detect issues such as imbalances, misalignment, and bearing wear. It helps prevent mechanical failure by providing early warning signs.

Q2: Is the Bently Nevada 330730 080 00 00 suitable for harsh environments?

A2: Yes, the device is designed to operate in harsh industrial environments and has been built to withstand extreme temperatures and rugged conditions.

Q3: How does the Bently Nevada 330730 080 00 00 communicate with other systems?

A3: It supports Modbus RTU and Profibus DP communication protocols, allowing for easy integration with other monitoring and control systems.

Q4: What are the power requirements for the Bently Nevada 330730 080 00 00?

A4: It operates with a 24 VDC power supply.

Q5: How many input channels does the 330730 080 00 00 support?

A5: This model supports 4 analog input channels for connecting vibration transducers.

Q6: Can the system detect specific machine faults?

A6: Yes, the system is capable of detecting specific faults such as imbalances, misalignments, and bearing wear through advanced signal processing techniques.

Q7: How is the data from the 330730 080 00 00 stored?

A7: The data is typically stored in a connected monitoring system, either locally or remotely, for analysis and historical tracking.

Q8: Does the 330730 080 00 00 provide alarm functions?

A8: Yes, the system can trigger alarms for out-of-range vibration levels or other detected faults, providing early warning for maintenance personnel.

Q9: What industries commonly use the Bently Nevada 330730 080 00 00?

A9: It is widely used in industries such as power generation, oil & gas, manufacturing, and mining for machinery health monitoring.

Q10: Is it easy to install the 330730 080 00 00?

A10: Yes, installation is straightforward, and the unit is designed for ease of integration into existing monitoring setups.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...