Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

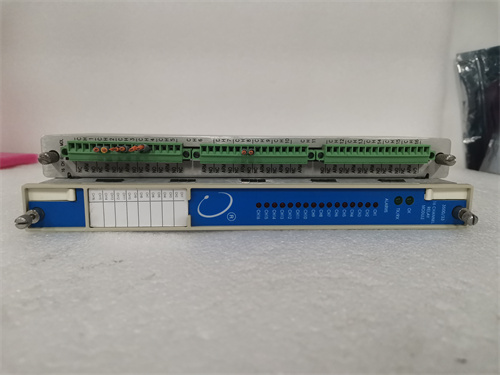

Bently Nevada 3500/50M 288062-02+136703-01 Speedometer Module

Manufacturer:Bently Nevada

Product Number:3500/50M 288062-02+136703-01

Product Type:Speedometer Module

Origin:USA

Dimensions:241.3 x 24.4 x 241.8mm

Weight:0.82kg

Views:58

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/50M 288062-02+136703-01 Speedometer Module is a critical component of the 3500 Series machinery protection and condition monitoring system. Designed for high-precision monitoring of the rotational speed of key equipment such as turbines, motors, pumps, and compressors, this module helps ensure operational efficiency and safety. By providing real-time data on equipment speed, the 3500/50M Speedometer Module enables early detection of potential issues such as misalignment, imbalance, or wear, reducing the risk of costly breakdowns and downtime.

This module integrates seamlessly with the Bently Nevada 3500 monitoring system, providing a comprehensive solution for monitoring the health of industrial assets. The 3500/50M 288062-02+136703-01 is ideal for industries where rotating equipment is essential, including power generation, oil and gas, and manufacturing. It ensures that machinery operates within optimal parameters and facilitates predictive maintenance, enhancing overall system reliability and performance.

Product Parameters

Below is the detailed specification of the Bently Nevada 3500/50M 288062-02+136703-01 Speedometer Module:

| Parameter | Value |

|---|---|

| Model | 3500/50M 288062-02+136703-01 |

| Dimensions (L x W x H) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.82 kg |

| Signal Input | Tachometer signal, frequency input |

| Signal Output | Speed measurement output (digital/analog) |

| Power Supply | 24 V DC |

| Operating Temperature Range | -40°C to 85°C |

| Mounting Type | Rack mount |

| Signal Compatibility | Compatible with tachometers, vibration sensors |

| Data Update Rate | 500 ms |

| Communication Interface | Integrated with 3500 Series Monitoring System |

| Environmental Protection | IP20 rated |

Product Applications

The 3500/50M 288062-02+136703-01 Speedometer Module has broad applications in various industries where continuous monitoring of rotational machinery is essential. Some common applications include:

-

Power Generation: Used to monitor the speed of turbines, generators, and other critical rotating equipment in power plants. This ensures that the equipment is running at optimal speeds for efficiency and safety.

-

Oil and Gas: This module is used in both upstream and downstream operations to monitor pumps, compressors, and other machinery, reducing the risk of failure and improving operational efficiency.

-

Manufacturing: It is employed to monitor motors, conveyor belts, and other rotating machinery, ensuring that production lines run smoothly without interruptions.

-

Mining: In mining operations, the module monitors crushers, mills, and other heavy-duty equipment, ensuring they operate within safe speed limits and preventing unnecessary wear and tear.

-

Water Treatment: The module monitors pumps and motors in water treatment facilities, ensuring that the processes operate efficiently without interruptions.

-

HVAC Systems: In HVAC systems, it helps monitor fan and pump speeds, ensuring proper functioning of heating, ventilation, and air conditioning systems.

-

Critical Infrastructure: Used in various critical infrastructure systems such as elevators, escalators, and water distribution systems to ensure that all rotating machinery operates within safe speed limits.

Product Advantages

The 3500/50M 288062-02+136703-01 Speedometer Module offers several significant advantages, making it an essential component in industrial machinery monitoring systems:

-

High Precision and Reliability: The module provides accurate, real-time monitoring of rotational speed, helping detect issues such as imbalance or misalignment before they lead to equipment failure.

-

Wide Speed Measurement Range: It is capable of measuring speeds from 0 to 10,000 RPM, which makes it adaptable to a wide range of rotating equipment.

-

Ease of Integration: Seamlessly integrates with the Bently Nevada 3500 monitoring system, allowing for efficient data collection and analysis.

-

Durable in Harsh Environments: With an operating temperature range of -40°C to 85°C, the module is built to withstand extreme environmental conditions.

-

Compact Design: The module is lightweight and compact (241.3 x 24.4 x 241.8 mm, 0.82 kg), making it easy to install in space-constrained areas within control panels.

-

Predictive Maintenance: By detecting anomalies in rotational speed, the module helps predict mechanical failures, allowing maintenance teams to intervene before costly repairs or shutdowns are necessary.

-

Flexible Signal Output: The module supports both digital and analog output signals, providing flexibility in how data is processed and transmitted.

-

Energy-Efficient: Operating on 24 V DC, it is energy-efficient and suitable for long-term use in industrial settings.

-

Real-Time Diagnostics: Offers immediate feedback to operators, helping them make data-driven decisions for maintenance and repairs.

-

Cost-Effective: Prevents unplanned downtime and reduces maintenance costs by enabling early detection of potential failures.

Frequently Asked Questions (FAQ)

-

What is the main function of the Bently Nevada 3500/50M 288062-02+136703-01 Speedometer Module?

-

The module monitors the rotational speed of machinery such as turbines, motors, and pumps, ensuring they operate efficiently and safely.

-

-

What speed range can the 3500/50M module measure?

-

It can measure speeds from 0 to 10,000 RPM, making it suitable for a wide range of rotating equipment.

-

-

What is the power requirement for this module?

-

The module operates on a 24 V DC power supply.

-

-

What is the operating temperature range for this module?

-

The operating temperature range is -40°C to 85°C, making it ideal for harsh industrial environments.

-

-

How is the Bently Nevada 3500/50M module mounted?

-

It is mounted using a rack mount configuration, making installation simple and efficient.

-

-

What types of signals does the module handle?

-

The module handles tachometer signals, providing both digital and analog outputs for speed measurement.

-

-

How does this module help in predictive maintenance?

-

The module helps detect anomalies in equipment speed, allowing maintenance teams to intervene before failures occur, thus minimizing unplanned downtime.

-

-

What industries benefit from the use of the 3500/50M module?

-

Industries such as power generation, oil and gas, manufacturing, mining, water treatment, and HVAC systems benefit from this module.

-

-

How does the 3500/50M module integrate with other systems?

-

It integrates seamlessly with the Bently Nevada 3500 monitoring system, allowing data sharing across a variety of monitoring modules.

-

-

What is the weight of the 3500/50M module?

-

The module weighs 0.82 kg, making it lightweight and easy to handle during installation.

-

Bently Nevada 3500/50M 288062-02+136703-01 Speedometer Module

Manufacturer:Bently Nevada

Product Number:3500/50M 288062-02+136703-01

Product Type:Speedometer Module

Origin:USA

Dimensions:241.3 x 24.4 x 241.8mm

Weight:0.82kg

Views:58

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/50M 288062-02+136703-01 Speedometer Module is a critical component of the 3500 Series machinery protection and condition monitoring system. Designed for high-precision monitoring of the rotational speed of key equipment such as turbines, motors, pumps, and compressors, this module helps ensure operational efficiency and safety. By providing real-time data on equipment speed, the 3500/50M Speedometer Module enables early detection of potential issues such as misalignment, imbalance, or wear, reducing the risk of costly breakdowns and downtime.

This module integrates seamlessly with the Bently Nevada 3500 monitoring system, providing a comprehensive solution for monitoring the health of industrial assets. The 3500/50M 288062-02+136703-01 is ideal for industries where rotating equipment is essential, including power generation, oil and gas, and manufacturing. It ensures that machinery operates within optimal parameters and facilitates predictive maintenance, enhancing overall system reliability and performance.

Product Parameters

Below is the detailed specification of the Bently Nevada 3500/50M 288062-02+136703-01 Speedometer Module:

| Parameter | Value |

|---|---|

| Model | 3500/50M 288062-02+136703-01 |

| Dimensions (L x W x H) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.82 kg |

| Signal Input | Tachometer signal, frequency input |

| Signal Output | Speed measurement output (digital/analog) |

| Power Supply | 24 V DC |

| Operating Temperature Range | -40°C to 85°C |

| Mounting Type | Rack mount |

| Signal Compatibility | Compatible with tachometers, vibration sensors |

| Data Update Rate | 500 ms |

| Communication Interface | Integrated with 3500 Series Monitoring System |

| Environmental Protection | IP20 rated |

Product Applications

The 3500/50M 288062-02+136703-01 Speedometer Module has broad applications in various industries where continuous monitoring of rotational machinery is essential. Some common applications include:

-

Power Generation: Used to monitor the speed of turbines, generators, and other critical rotating equipment in power plants. This ensures that the equipment is running at optimal speeds for efficiency and safety.

-

Oil and Gas: This module is used in both upstream and downstream operations to monitor pumps, compressors, and other machinery, reducing the risk of failure and improving operational efficiency.

-

Manufacturing: It is employed to monitor motors, conveyor belts, and other rotating machinery, ensuring that production lines run smoothly without interruptions.

-

Mining: In mining operations, the module monitors crushers, mills, and other heavy-duty equipment, ensuring they operate within safe speed limits and preventing unnecessary wear and tear.

-

Water Treatment: The module monitors pumps and motors in water treatment facilities, ensuring that the processes operate efficiently without interruptions.

-

HVAC Systems: In HVAC systems, it helps monitor fan and pump speeds, ensuring proper functioning of heating, ventilation, and air conditioning systems.

-

Critical Infrastructure: Used in various critical infrastructure systems such as elevators, escalators, and water distribution systems to ensure that all rotating machinery operates within safe speed limits.

Product Advantages

The 3500/50M 288062-02+136703-01 Speedometer Module offers several significant advantages, making it an essential component in industrial machinery monitoring systems:

-

High Precision and Reliability: The module provides accurate, real-time monitoring of rotational speed, helping detect issues such as imbalance or misalignment before they lead to equipment failure.

-

Wide Speed Measurement Range: It is capable of measuring speeds from 0 to 10,000 RPM, which makes it adaptable to a wide range of rotating equipment.

-

Ease of Integration: Seamlessly integrates with the Bently Nevada 3500 monitoring system, allowing for efficient data collection and analysis.

-

Durable in Harsh Environments: With an operating temperature range of -40°C to 85°C, the module is built to withstand extreme environmental conditions.

-

Compact Design: The module is lightweight and compact (241.3 x 24.4 x 241.8 mm, 0.82 kg), making it easy to install in space-constrained areas within control panels.

-

Predictive Maintenance: By detecting anomalies in rotational speed, the module helps predict mechanical failures, allowing maintenance teams to intervene before costly repairs or shutdowns are necessary.

-

Flexible Signal Output: The module supports both digital and analog output signals, providing flexibility in how data is processed and transmitted.

-

Energy-Efficient: Operating on 24 V DC, it is energy-efficient and suitable for long-term use in industrial settings.

-

Real-Time Diagnostics: Offers immediate feedback to operators, helping them make data-driven decisions for maintenance and repairs.

-

Cost-Effective: Prevents unplanned downtime and reduces maintenance costs by enabling early detection of potential failures.

Frequently Asked Questions (FAQ)

-

What is the main function of the Bently Nevada 3500/50M 288062-02+136703-01 Speedometer Module?

-

The module monitors the rotational speed of machinery such as turbines, motors, and pumps, ensuring they operate efficiently and safely.

-

-

What speed range can the 3500/50M module measure?

-

It can measure speeds from 0 to 10,000 RPM, making it suitable for a wide range of rotating equipment.

-

-

What is the power requirement for this module?

-

The module operates on a 24 V DC power supply.

-

-

What is the operating temperature range for this module?

-

The operating temperature range is -40°C to 85°C, making it ideal for harsh industrial environments.

-

-

How is the Bently Nevada 3500/50M module mounted?

-

It is mounted using a rack mount configuration, making installation simple and efficient.

-

-

What types of signals does the module handle?

-

The module handles tachometer signals, providing both digital and analog outputs for speed measurement.

-

-

How does this module help in predictive maintenance?

-

The module helps detect anomalies in equipment speed, allowing maintenance teams to intervene before failures occur, thus minimizing unplanned downtime.

-

-

What industries benefit from the use of the 3500/50M module?

-

Industries such as power generation, oil and gas, manufacturing, mining, water treatment, and HVAC systems benefit from this module.

-

-

How does the 3500/50M module integrate with other systems?

-

It integrates seamlessly with the Bently Nevada 3500 monitoring system, allowing data sharing across a variety of monitoring modules.

-

-

What is the weight of the 3500/50M module?

-

The module weighs 0.82 kg, making it lightweight and easy to handle during installation.

-

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...