Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

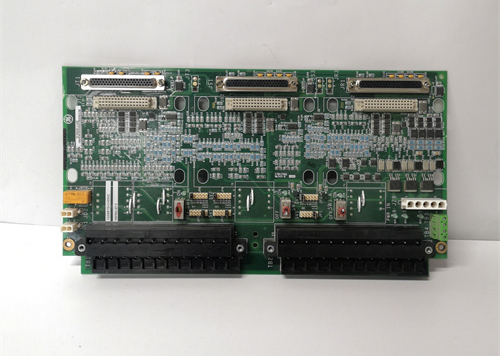

General Electric IS200WETBH1A Mark VIe Top Box B Module

Manufacturer:GE

Product Number:IS200WETBH1A

Product Type:Mark VIe Top Box B Module

Origin:USA

Dimensions:178 x 51 x 305 mm

Weight:1.4 kg

Views:42

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200WETBH1A is a Top Box B (WETB) interface module developed for use within GE’s Mark VIe control systems. It plays a crucial role in providing analog signal conditioning, electrical isolation, and signal conversion for a variety of industrial control and monitoring systems. As part of the Wide-range Electronic Transducer Assembly (WETA) family, the WETBH1A module enables seamless integration between field sensors and GE’s high-performance control infrastructure.

This module is specifically engineered for demanding environments where reliability, accuracy, and robust signal handling are essential. Its design is tailored for compatibility with gas and steam turbine controls, generator excitation systems, and other mission-critical control systems. The WETBH1A interfaces with a wide range of input types and ensures precise signal transfer to controller modules, maintaining the integrity of the overall control loop.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IS200WETBH1A |

| Manufacturer | General Electric (GE) |

| Product Type | Interface Module – Top Box B |

| Series | Mark VIe / EX2100 |

| Signal Input Type | Analog input (typically ±10V, 4–20 mA) |

| Signal Output Type | Conditioned analog signal to control processor |

| Primary Function | Signal conditioning, isolation, and communication |

| Input Channels | Multiple isolated analog input channels |

| Isolation Type | Optical and galvanic isolation |

| Diagnostic Features | Fault LEDs, signal integrity monitoring, watchdog circuits |

| Control Compatibility | Mark VIe, EX2100, LS2100 systems |

| Mounting Style | Mounted within WETA Top Box enclosure |

| Cooling Mechanism | Passive (natural convection within top box housing) |

| Redundancy Support | Yes, suitable for redundant system configurations |

| Communication Interface | Proprietary GE backplane bus |

| Power Requirements | 28V DC nominal |

| Operating Temperature | -30°C to +65°C |

| Humidity | 5–95% non-condensing |

| Firmware | Configurable using GE ToolboxST software |

| Certifications | CE, UL, RoHS compliant (depending on system integration) |

| Dimensions (L x W x H) | 178 x 51 x 305 mm |

| Weight | 1.4 kg |

Product Applications

-

Gas and Steam Turbine Control

Converts and transmits precise analog field signals such as pressure, temperature, and speed sensor outputs to Mark VIe controllers.

-

Generator Excitation Control (EX2100)

Facilitates signal transfer between analog sensors and voltage regulator systems in generator excitation.

-

Process Automation in Energy Plants

Offers electrical isolation and signal integrity required for field instrumentation in power plant DCS/PLC architectures.

-

SCADA Interfacing

Serves as a stable analog signal gateway from local sensors to centralized SCADA or HMI systems.

-

Oil & Gas Industry Applications

Performs under high-temperature and electromagnetic noise conditions for refinery and upstream automation.

-

Redundant and Safety-Critical Systems

Fully compatible with systems requiring redundant signal paths and real-time diagnostic feedback.

Product Advantages

-

Robust Signal Isolation

Protects system integrity and control processors by isolating analog inputs from electrical disturbances.

-

High-Precision Signal Conditioning

Maintains accuracy in sensor readings through amplification, filtering, and range conversion.

-

Integrated Diagnostics

Onboard fault indicators and self-monitoring circuits support fast fault location and predictive maintenance.

-

Redundant System Ready

Fully capable of supporting high-availability architectures required in turbine and critical process systems.

-

ToolboxST Integration

Streamlined configuration and diagnostics using GE’s engineering software platform.

-

Reliable in Harsh Environments

Designed to withstand electrical noise, high temperatures, and humidity typical of industrial operations.

FAQ

-

What types of analog inputs are supported by IS200WETBH1A?

The module supports current (e.g., 4–20 mA) and voltage (e.g., ±10V) analog inputs from field sensors.

-

How are signal channels isolated within this module?

The module uses a combination of optical and galvanic isolation to prevent cross-talk and protect the control system.

-

Can this module be configured through GE’s ToolboxST software?

Yes, it is fully compatible with ToolboxST for calibration, diagnostics, and configuration.

-

Is the WETBH1A compatible with redundant controller configurations?

Absolutely. It supports dual-channel redundant input and output pathways.

-

What is the response time for analog signal processing?

The signal processing is real-time, with low-latency operation suitable for turbine speed and temperature feedback loops.

-

Does the module provide any status indication?

Yes, it features onboard diagnostic LEDs and status monitoring features for live feedback.

-

How many analog input channels are available on this board?

Typically, the module supports 8–16 analog channels depending on the WETA box configuration.

-

How is signal noise minimized?

The module includes built-in filtering and shielding to suppress EMI and RFI influences.

-

Is hot-swapping supported by the module?

Hot-swapping is not recommended unless specifically supported by the enclosure and overall control architecture.

-

How is the board protected against overvoltage or surge?

It includes overvoltage protection circuits and clamping to ensure protection from transient events.

General Electric IS200WETBH1A Mark VIe Top Box B Module

Manufacturer:GE

Product Number:IS200WETBH1A

Product Type:Mark VIe Top Box B Module

Origin:USA

Dimensions:178 x 51 x 305 mm

Weight:1.4 kg

Views:42

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200WETBH1A is a Top Box B (WETB) interface module developed for use within GE’s Mark VIe control systems. It plays a crucial role in providing analog signal conditioning, electrical isolation, and signal conversion for a variety of industrial control and monitoring systems. As part of the Wide-range Electronic Transducer Assembly (WETA) family, the WETBH1A module enables seamless integration between field sensors and GE’s high-performance control infrastructure.

This module is specifically engineered for demanding environments where reliability, accuracy, and robust signal handling are essential. Its design is tailored for compatibility with gas and steam turbine controls, generator excitation systems, and other mission-critical control systems. The WETBH1A interfaces with a wide range of input types and ensures precise signal transfer to controller modules, maintaining the integrity of the overall control loop.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IS200WETBH1A |

| Manufacturer | General Electric (GE) |

| Product Type | Interface Module – Top Box B |

| Series | Mark VIe / EX2100 |

| Signal Input Type | Analog input (typically ±10V, 4–20 mA) |

| Signal Output Type | Conditioned analog signal to control processor |

| Primary Function | Signal conditioning, isolation, and communication |

| Input Channels | Multiple isolated analog input channels |

| Isolation Type | Optical and galvanic isolation |

| Diagnostic Features | Fault LEDs, signal integrity monitoring, watchdog circuits |

| Control Compatibility | Mark VIe, EX2100, LS2100 systems |

| Mounting Style | Mounted within WETA Top Box enclosure |

| Cooling Mechanism | Passive (natural convection within top box housing) |

| Redundancy Support | Yes, suitable for redundant system configurations |

| Communication Interface | Proprietary GE backplane bus |

| Power Requirements | 28V DC nominal |

| Operating Temperature | -30°C to +65°C |

| Humidity | 5–95% non-condensing |

| Firmware | Configurable using GE ToolboxST software |

| Certifications | CE, UL, RoHS compliant (depending on system integration) |

| Dimensions (L x W x H) | 178 x 51 x 305 mm |

| Weight | 1.4 kg |

Product Applications

-

Gas and Steam Turbine Control

Converts and transmits precise analog field signals such as pressure, temperature, and speed sensor outputs to Mark VIe controllers.

-

Generator Excitation Control (EX2100)

Facilitates signal transfer between analog sensors and voltage regulator systems in generator excitation.

-

Process Automation in Energy Plants

Offers electrical isolation and signal integrity required for field instrumentation in power plant DCS/PLC architectures.

-

SCADA Interfacing

Serves as a stable analog signal gateway from local sensors to centralized SCADA or HMI systems.

-

Oil & Gas Industry Applications

Performs under high-temperature and electromagnetic noise conditions for refinery and upstream automation.

-

Redundant and Safety-Critical Systems

Fully compatible with systems requiring redundant signal paths and real-time diagnostic feedback.

Product Advantages

-

Robust Signal Isolation

Protects system integrity and control processors by isolating analog inputs from electrical disturbances.

-

High-Precision Signal Conditioning

Maintains accuracy in sensor readings through amplification, filtering, and range conversion.

-

Integrated Diagnostics

Onboard fault indicators and self-monitoring circuits support fast fault location and predictive maintenance.

-

Redundant System Ready

Fully capable of supporting high-availability architectures required in turbine and critical process systems.

-

ToolboxST Integration

Streamlined configuration and diagnostics using GE’s engineering software platform.

-

Reliable in Harsh Environments

Designed to withstand electrical noise, high temperatures, and humidity typical of industrial operations.

FAQ

-

What types of analog inputs are supported by IS200WETBH1A?

The module supports current (e.g., 4–20 mA) and voltage (e.g., ±10V) analog inputs from field sensors.

-

How are signal channels isolated within this module?

The module uses a combination of optical and galvanic isolation to prevent cross-talk and protect the control system.

-

Can this module be configured through GE’s ToolboxST software?

Yes, it is fully compatible with ToolboxST for calibration, diagnostics, and configuration.

-

Is the WETBH1A compatible with redundant controller configurations?

Absolutely. It supports dual-channel redundant input and output pathways.

-

What is the response time for analog signal processing?

The signal processing is real-time, with low-latency operation suitable for turbine speed and temperature feedback loops.

-

Does the module provide any status indication?

Yes, it features onboard diagnostic LEDs and status monitoring features for live feedback.

-

How many analog input channels are available on this board?

Typically, the module supports 8–16 analog channels depending on the WETA box configuration.

-

How is signal noise minimized?

The module includes built-in filtering and shielding to suppress EMI and RFI influences.

-

Is hot-swapping supported by the module?

Hot-swapping is not recommended unless specifically supported by the enclosure and overall control architecture.

-

How is the board protected against overvoltage or surge?

It includes overvoltage protection circuits and clamping to ensure protection from transient events.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...