Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

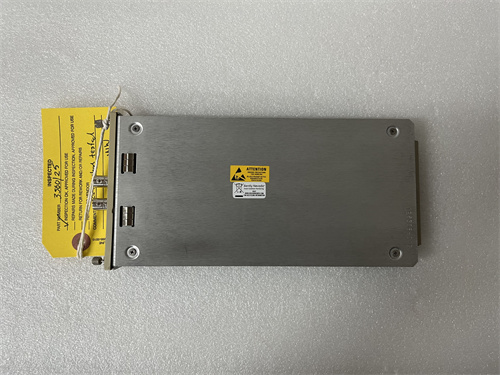

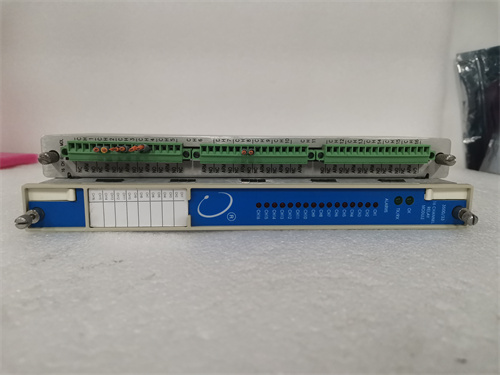

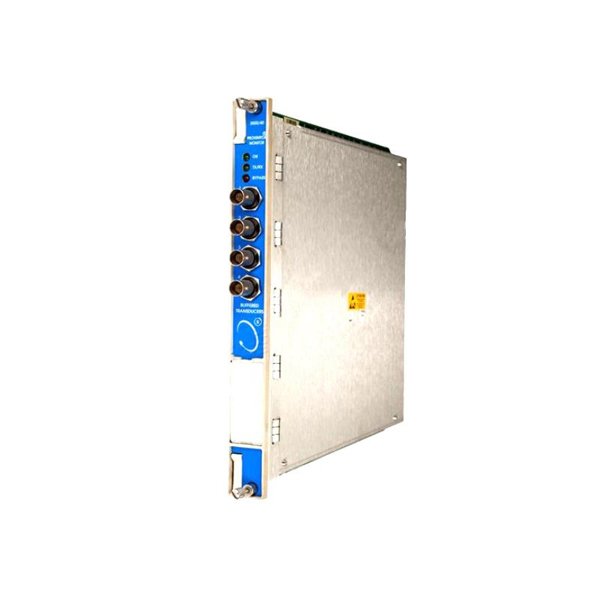

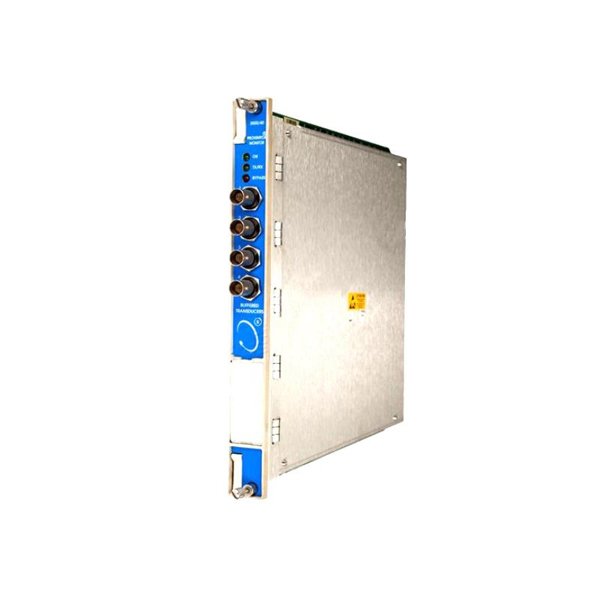

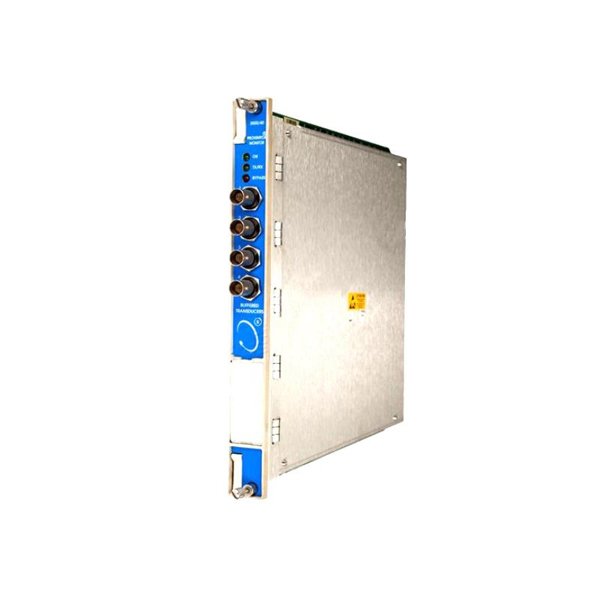

Bently Nevada 3500/40-01-00 3500-40M Proximitor Monitor

Manufacturer:Bently Nevada

Product Number:3500/40-01-00

Product Type:3500-40M Proximitor Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:100

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/40-01-00 Proximitor Monitor is a four-channel module designed to interface with Bently Nevada proximity transducers. It conditions input signals to provide various vibration and position measurements, comparing them with user-defined alarms. Each channel can be configured for functions such as radial vibration, thrust position, differential expansion, and eccentricity, making it a versatile component in machinery protection systems.

Product Specifications

| Parameter | Details |

| Model Number | 3500/40-01-00 (3500/40M) |

| Channels | 4 independent channels |

| Input Type | Bently Nevada proximity transducers |

| Output Impedance | 550 Ω |

| Transducer Power Supply | -24 VDC |

| Alarm Setpoints | User-programmable for each channel |

| Operating Temperature | -30°C to +65°C (-22°F to +150°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Humidity Range | 0% to 95% non-condensing |

| Certifications | CE, CSA, ATEX, IECEx, GOST |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

Product Applications

-

Machinery Protection Systems: Monitors critical parameters in turbines, compressors, and pumps.

-

Process Control Integration: Interfaces with DCS and PLC systems for comprehensive process monitoring.

-

Safety Systems: Implements voting logic for critical safety applications requiring high reliability.

-

Industrial Automation: Used in various industries including oil and gas, power generation, and manufacturing for equipment protection.

Product Advantages

-

Flexible Configuration: Each channel can be independently programmed for specific monitoring functions.

-

High Reliability: Designed for long operational life with robust construction.

-

Seamless Integration: Easily integrates into existing 3500 rack systems without additional hardware.

-

Global Certifications: Meets international standards for use in hazardous environments.

Frequently Asked Questions (FAQ)

-

What is the function of the 3500/40M module?

-

It provides four channels for monitoring vibration and position parameters in machinery protection systems.

-

-

Can each channel be configured independently?

-

Yes, each channel can be programmed separately for specific monitoring functions.

-

-

What types of measurements can the module perform?

-

It can measure radial vibration, thrust position, differential expansion, and eccentricity.

-

-

Is the module compatible with hazardous environments?

-

Yes, it has certifications including ATEX, CSA, IECEx, and GOST for use in hazardous areas.

-

-

Where is the module installed in the 3500 rack?

-

It occupies one full-height front slot and requires a corresponding I/O module in the rear slot.

-

-

What is the power supply requirement for the transducers?

-

The module provides a -24 VDC power supply for the transducers.

-

-

What is the output impedance of the module?

-

The output impedance is 550 Ω.

-

-

What is the operational temperature range?

-

The module operates between -30°C and +65°C (-22°F to +150°F).

-

-

Can the module be used in redundant configurations?

-

Yes, multiple modules can be used to provide redundancy in critical applications.

-

-

Is the module compatible with all 3500 series systems?

-

Yes, it is designed to integrate seamlessly with the entire 3500 series.

-

Bently Nevada 3500/40-01-00 3500-40M Proximitor Monitor

Manufacturer:Bently Nevada

Product Number:3500/40-01-00

Product Type:3500-40M Proximitor Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:100

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/40-01-00 Proximitor Monitor is a four-channel module designed to interface with Bently Nevada proximity transducers. It conditions input signals to provide various vibration and position measurements, comparing them with user-defined alarms. Each channel can be configured for functions such as radial vibration, thrust position, differential expansion, and eccentricity, making it a versatile component in machinery protection systems.

Product Specifications

| Parameter | Details |

| Model Number | 3500/40-01-00 (3500/40M) |

| Channels | 4 independent channels |

| Input Type | Bently Nevada proximity transducers |

| Output Impedance | 550 Ω |

| Transducer Power Supply | -24 VDC |

| Alarm Setpoints | User-programmable for each channel |

| Operating Temperature | -30°C to +65°C (-22°F to +150°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Humidity Range | 0% to 95% non-condensing |

| Certifications | CE, CSA, ATEX, IECEx, GOST |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

Product Applications

-

Machinery Protection Systems: Monitors critical parameters in turbines, compressors, and pumps.

-

Process Control Integration: Interfaces with DCS and PLC systems for comprehensive process monitoring.

-

Safety Systems: Implements voting logic for critical safety applications requiring high reliability.

-

Industrial Automation: Used in various industries including oil and gas, power generation, and manufacturing for equipment protection.

Product Advantages

-

Flexible Configuration: Each channel can be independently programmed for specific monitoring functions.

-

High Reliability: Designed for long operational life with robust construction.

-

Seamless Integration: Easily integrates into existing 3500 rack systems without additional hardware.

-

Global Certifications: Meets international standards for use in hazardous environments.

Frequently Asked Questions (FAQ)

-

What is the function of the 3500/40M module?

-

It provides four channels for monitoring vibration and position parameters in machinery protection systems.

-

-

Can each channel be configured independently?

-

Yes, each channel can be programmed separately for specific monitoring functions.

-

-

What types of measurements can the module perform?

-

It can measure radial vibration, thrust position, differential expansion, and eccentricity.

-

-

Is the module compatible with hazardous environments?

-

Yes, it has certifications including ATEX, CSA, IECEx, and GOST for use in hazardous areas.

-

-

Where is the module installed in the 3500 rack?

-

It occupies one full-height front slot and requires a corresponding I/O module in the rear slot.

-

-

What is the power supply requirement for the transducers?

-

The module provides a -24 VDC power supply for the transducers.

-

-

What is the output impedance of the module?

-

The output impedance is 550 Ω.

-

-

What is the operational temperature range?

-

The module operates between -30°C and +65°C (-22°F to +150°F).

-

-

Can the module be used in redundant configurations?

-

Yes, multiple modules can be used to provide redundancy in critical applications.

-

-

Is the module compatible with all 3500 series systems?

-

Yes, it is designed to integrate seamlessly with the entire 3500 series.

-

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...