Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

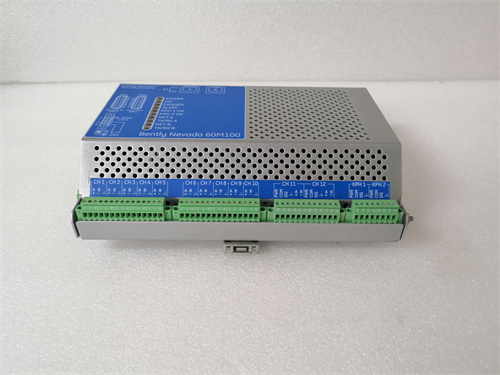

Bently Nevada 3300/55-01-04-02-02-01-00-06-00 Dual Velocity Monitor

Manufacturer:Bently Nevada

Product Number:3300/55-01-04-02-02-01-00-06-00

Product Type:Dual Velocity Monitor

Origin:USA

Vertical Dimension:83 mm

Weight:1 kg

Views:64

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3300/55-01-04-02-02-01-00-06-00 Dual Velocity Monitor is a high-performance monitoring system designed to provide real-time velocity measurements for rotating machinery. This unit is part of the widely adopted Bently Nevada 3300 series, known for its reliability in industrial environments.

This monitor supports dual-channel velocity measurement, making it ideal for detecting early-stage mechanical failures, including unbalance, misalignment, and structural looseness in machinery such as turbines, compressors, motors, pumps, and fans. The 3300/55 model integrates seamlessly with Bently Nevada’s system architecture, providing critical data for preventive maintenance and system protection.

Product Specifications

| Parameter | Details |

|---|---|

| Model | 3300/55-01-04-02-02-01-00-06-00 |

| Measurement Type | Velocity (dual-channel) |

| Input Type | Velomitor® transducers, Velocity Seismoprobe® |

| Frequency Response | 3 Hz to 10,000 Hz (180 to 600,000 CPM) |

| Sensitivity | 500 mV/in/s, 145 mV/in/s, 100 mV/in/s |

| Alarm Setpoints | Adjustable from 0 to 100% full scale |

| Outputs | 4-20 mA, 0-10 VDC, 1-5 VDC |

| Power Supply | 24V DC |

| Operating Temperature | 0°C to +65°C (32°F to 150°F) |

| Vertical Dimension | 83 mm |

| Weight | 1 kg |

Applications

The Bently Nevada 3300/55 Dual Velocity Monitor is widely used across industries where machinery vibration monitoring is critical. Common applications include:

-

Power Generation – Monitors steam turbines, gas turbines, and hydro turbines for abnormal vibrations.

-

Oil & Gas – Ensures compressors and pumps operate within acceptable vibration levels.

-

Petrochemical Industry – Provides continuous monitoring of pumps and motors in refineries.

-

Manufacturing Plants – Protects rotating machinery in production lines.

-

Steel & Mining Industry – Monitors large conveyor systems, crushers, and rotating equipment.

-

Marine Industry – Ensures the smooth operation of ship propulsion systems and auxiliary engines.

Advantages

Dual-Channel Monitoring – Allows for simultaneous monitoring of two independent velocity signals.

Wide Frequency Range – Covers a broad spectrum of vibration issues, ensuring early fault detection.

High Sensitivity Options – Multiple sensitivity settings allow adaptability to different machine conditions.

Configurable Outputs – Provides flexible connectivity with control and automation systems.

Reliable Alarm System – Programmable alarm setpoints prevent equipment damage and downtime.

Industry-Proven Durability – Built for harsh environments with industrial-grade materials.

Seamless Integration – Compatible with Bently Nevada’s 3300 and 3500 monitoring systems.

Frequently Asked Questions (FAQ)

-

What is the purpose of the Bently Nevada 3300/55 Dual Velocity Monitor?

-

The device measures and monitors vibration velocity in rotating machinery to prevent failures.

-

-

How does this model differ from other vibration monitors?

-

It features dual-channel monitoring, multiple sensitivity settings, and high-precision alarm triggers.

-

-

What types of transducers are compatible with the 3300/55?

-

It supports Velomitor® transducers and Velocity Seismoprobe® sensors.

-

-

Can this monitor be used in hazardous environments?

-

Yes, it is designed for industrial environments, including extreme temperatures and high-vibration areas.

-

-

What are the power requirements for the 3300/55?

-

It operates on a 24V DC power supply.

-

-

How does the alarm system work?

-

It has adjustable setpoints that trigger alerts when vibration levels exceed safe thresholds.

-

-

Can the 3300/55 be integrated with other monitoring systems?

-

Yes, it is fully compatible with Bently Nevada’s 3300 and 3500 series monitoring systems.

-

-

What are the dimensions of this display?

-

Vertical Dimension is 83 mm.

-

-

Is the 3300/55 suitable for marine applications?

-

Yes, it is commonly used for monitoring ship propulsion systems and auxiliary engines.

-

-

Does this monitor provide real-time data?

-

Yes, it continuously measures and transmits real-time vibration velocity data.

Bently Nevada 3300/55-01-04-02-02-01-00-06-00 Dual Velocity Monitor

Manufacturer:Bently Nevada

Product Number:3300/55-01-04-02-02-01-00-06-00

Product Type:Dual Velocity Monitor

Origin:USA

Vertical Dimension:83 mm

Weight:1 kg

Views:64

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3300/55-01-04-02-02-01-00-06-00 Dual Velocity Monitor is a high-performance monitoring system designed to provide real-time velocity measurements for rotating machinery. This unit is part of the widely adopted Bently Nevada 3300 series, known for its reliability in industrial environments.

This monitor supports dual-channel velocity measurement, making it ideal for detecting early-stage mechanical failures, including unbalance, misalignment, and structural looseness in machinery such as turbines, compressors, motors, pumps, and fans. The 3300/55 model integrates seamlessly with Bently Nevada’s system architecture, providing critical data for preventive maintenance and system protection.

Product Specifications

| Parameter | Details |

|---|---|

| Model | 3300/55-01-04-02-02-01-00-06-00 |

| Measurement Type | Velocity (dual-channel) |

| Input Type | Velomitor® transducers, Velocity Seismoprobe® |

| Frequency Response | 3 Hz to 10,000 Hz (180 to 600,000 CPM) |

| Sensitivity | 500 mV/in/s, 145 mV/in/s, 100 mV/in/s |

| Alarm Setpoints | Adjustable from 0 to 100% full scale |

| Outputs | 4-20 mA, 0-10 VDC, 1-5 VDC |

| Power Supply | 24V DC |

| Operating Temperature | 0°C to +65°C (32°F to 150°F) |

| Vertical Dimension | 83 mm |

| Weight | 1 kg |

Applications

The Bently Nevada 3300/55 Dual Velocity Monitor is widely used across industries where machinery vibration monitoring is critical. Common applications include:

-

Power Generation – Monitors steam turbines, gas turbines, and hydro turbines for abnormal vibrations.

-

Oil & Gas – Ensures compressors and pumps operate within acceptable vibration levels.

-

Petrochemical Industry – Provides continuous monitoring of pumps and motors in refineries.

-

Manufacturing Plants – Protects rotating machinery in production lines.

-

Steel & Mining Industry – Monitors large conveyor systems, crushers, and rotating equipment.

-

Marine Industry – Ensures the smooth operation of ship propulsion systems and auxiliary engines.

Advantages

Dual-Channel Monitoring – Allows for simultaneous monitoring of two independent velocity signals.

Wide Frequency Range – Covers a broad spectrum of vibration issues, ensuring early fault detection.

High Sensitivity Options – Multiple sensitivity settings allow adaptability to different machine conditions.

Configurable Outputs – Provides flexible connectivity with control and automation systems.

Reliable Alarm System – Programmable alarm setpoints prevent equipment damage and downtime.

Industry-Proven Durability – Built for harsh environments with industrial-grade materials.

Seamless Integration – Compatible with Bently Nevada’s 3300 and 3500 monitoring systems.

Frequently Asked Questions (FAQ)

-

What is the purpose of the Bently Nevada 3300/55 Dual Velocity Monitor?

-

The device measures and monitors vibration velocity in rotating machinery to prevent failures.

-

-

How does this model differ from other vibration monitors?

-

It features dual-channel monitoring, multiple sensitivity settings, and high-precision alarm triggers.

-

-

What types of transducers are compatible with the 3300/55?

-

It supports Velomitor® transducers and Velocity Seismoprobe® sensors.

-

-

Can this monitor be used in hazardous environments?

-

Yes, it is designed for industrial environments, including extreme temperatures and high-vibration areas.

-

-

What are the power requirements for the 3300/55?

-

It operates on a 24V DC power supply.

-

-

How does the alarm system work?

-

It has adjustable setpoints that trigger alerts when vibration levels exceed safe thresholds.

-

-

Can the 3300/55 be integrated with other monitoring systems?

-

Yes, it is fully compatible with Bently Nevada’s 3300 and 3500 series monitoring systems.

-

-

What are the dimensions of this display?

-

Vertical Dimension is 83 mm.

-

-

Is the 3300/55 suitable for marine applications?

-

Yes, it is commonly used for monitoring ship propulsion systems and auxiliary engines.

-

-

Does this monitor provide real-time data?

-

Yes, it continuously measures and transmits real-time vibration velocity data.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...