Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

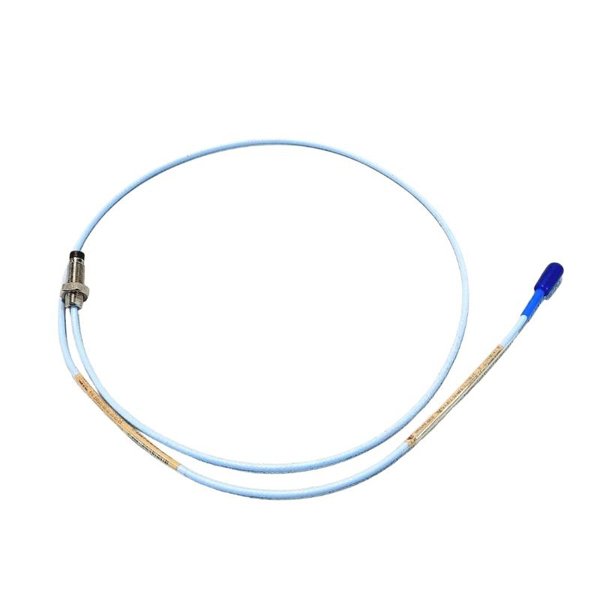

Bently Nevada 330103-00-12-05-12-00 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330103-00-12-05-12-00

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:0.5 meter

Weight:0.162 kg

Views:8

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-00-12-05-12-00, 3300 XL 8mm Proximity Probe is part of the 3300 XL series, designed for precise vibration and displacement measurements in industrial rotating machinery. This probe is widely used in condition monitoring and protection systems, where accurate shaft position and vibration data are critical to ensure machine reliability and operational safety.

This model integrates high-performance sensing technology with robust mechanical construction, making it suitable for harsh industrial environments. It works in combination with extension cables and Proximitor sensors to form a complete measurement system.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 330103-00-12-05-12-00 |

| Series | Bently Nevada 3300 XL 8mm Proximity Probe |

| Probe Tip Diameter | 8 mm |

| Total Length | 0.5 meter |

| Weight | 0.162 kg |

| Cable Length | 0.5 m fixed length |

| Connector Type | Standard coaxial connector |

| Material | Corrosion-resistant housing suitable for industrial environments |

| Frequency Response | DC to 10 kHz (typical for vibration/displacement measurement) |

| Operating Temperature Range | –35 °C to +180 °C |

| Linear Range | Up to 2 mm (typical with matching Proximitor) |

| Interchangeability | Fully interchangeable with other 3300 XL 8mm probes |

| Compliance | Meets API 670 standards |

Applications

The Bently Nevada 330103-00-12-05-12-00 probe is extensively applied in industries where high reliability is required. Its main uses include:

-

Monitoring shaft vibration in turbines, compressors, pumps, and motors.

-

Measuring shaft axial position and radial displacement.

-

Supporting machinery protection systems to prevent catastrophic failures.

-

Integration into predictive maintenance systems for trend monitoring.

-

Use in refineries, petrochemical plants, power generation, and heavy manufacturing.

Advantages

The 3300 XL 8mm probe delivers several benefits that make it a preferred choice in industrial condition monitoring:

-

High Accuracy: Provides precise measurement of shaft vibration and displacement, ensuring reliable data.

-

Wide Operating Range: Performs effectively across a broad temperature range and under harsh conditions.

-

Interchangeability: Designed for full interchangeability with other probes in the 3300 XL series, reducing downtime.

-

API Compliance: Meets API 670 standards, ensuring industry acceptance and compliance with safety protocols.

-

Durable Construction: Corrosion-resistant materials protect against industrial wear and tear.

-

Proven Reliability: Part of the well-established Bently Nevada monitoring system with decades of successful use worldwide.

FAQ

1. What is the typical linear measurement range of the 330103-00-12-05-12-00 probe?

The typical linear range is up to 2 mm, depending on the associated Proximitor and system configuration.

2. Can this probe operate reliably in high-temperature environments?

Yes, it is designed for continuous operation within –35 °C to +180 °C, suitable for most industrial machinery.

3. Does the probe require a dedicated extension cable?

Yes, it is designed to work with matching Bently Nevada extension cables for optimal performance and calibration accuracy.

4. Is the probe backward compatible with earlier Bently Nevada systems?

The 3300 XL 8mm probes are compatible with most existing 3300 Proximitor monitoring systems, ensuring backward integration.

5. What type of signal does the probe output?

The probe outputs a proportional voltage signal representing the shaft displacement or vibration amplitude.

6. How is the probe typically mounted on machinery?

It is installed in proximity to the shaft surface, usually in radial or axial measurement positions, using threaded mounting hardware.

7. What is the role of the probe within the overall monitoring system?

It forms the first sensing element, detecting shaft motion and transmitting data to the Proximitor and monitoring system.

8. How does cable length affect probe performance?

Cable length is factory-specified to maintain calibration. Deviating from standard lengths without recalibration may cause measurement errors.

9. Can this probe be used in hazardous or explosive environments?

Yes, with appropriate installation and certification, the probe can be deployed in hazardous areas, as it is designed for industrial compliance.

10. How does the probe ensure compliance with API 670 standards?

The probe meets requirements for accuracy, interchangeability, and reliability, fulfilling API 670 specifications for machinery protection.

Bently Nevada 330103-00-12-05-12-00 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330103-00-12-05-12-00

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:0.5 meter

Weight:0.162 kg

Views:8

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-00-12-05-12-00, 3300 XL 8mm Proximity Probe is part of the 3300 XL series, designed for precise vibration and displacement measurements in industrial rotating machinery. This probe is widely used in condition monitoring and protection systems, where accurate shaft position and vibration data are critical to ensure machine reliability and operational safety.

This model integrates high-performance sensing technology with robust mechanical construction, making it suitable for harsh industrial environments. It works in combination with extension cables and Proximitor sensors to form a complete measurement system.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 330103-00-12-05-12-00 |

| Series | Bently Nevada 3300 XL 8mm Proximity Probe |

| Probe Tip Diameter | 8 mm |

| Total Length | 0.5 meter |

| Weight | 0.162 kg |

| Cable Length | 0.5 m fixed length |

| Connector Type | Standard coaxial connector |

| Material | Corrosion-resistant housing suitable for industrial environments |

| Frequency Response | DC to 10 kHz (typical for vibration/displacement measurement) |

| Operating Temperature Range | –35 °C to +180 °C |

| Linear Range | Up to 2 mm (typical with matching Proximitor) |

| Interchangeability | Fully interchangeable with other 3300 XL 8mm probes |

| Compliance | Meets API 670 standards |

Applications

The Bently Nevada 330103-00-12-05-12-00 probe is extensively applied in industries where high reliability is required. Its main uses include:

-

Monitoring shaft vibration in turbines, compressors, pumps, and motors.

-

Measuring shaft axial position and radial displacement.

-

Supporting machinery protection systems to prevent catastrophic failures.

-

Integration into predictive maintenance systems for trend monitoring.

-

Use in refineries, petrochemical plants, power generation, and heavy manufacturing.

Advantages

The 3300 XL 8mm probe delivers several benefits that make it a preferred choice in industrial condition monitoring:

-

High Accuracy: Provides precise measurement of shaft vibration and displacement, ensuring reliable data.

-

Wide Operating Range: Performs effectively across a broad temperature range and under harsh conditions.

-

Interchangeability: Designed for full interchangeability with other probes in the 3300 XL series, reducing downtime.

-

API Compliance: Meets API 670 standards, ensuring industry acceptance and compliance with safety protocols.

-

Durable Construction: Corrosion-resistant materials protect against industrial wear and tear.

-

Proven Reliability: Part of the well-established Bently Nevada monitoring system with decades of successful use worldwide.

FAQ

1. What is the typical linear measurement range of the 330103-00-12-05-12-00 probe?

The typical linear range is up to 2 mm, depending on the associated Proximitor and system configuration.

2. Can this probe operate reliably in high-temperature environments?

Yes, it is designed for continuous operation within –35 °C to +180 °C, suitable for most industrial machinery.

3. Does the probe require a dedicated extension cable?

Yes, it is designed to work with matching Bently Nevada extension cables for optimal performance and calibration accuracy.

4. Is the probe backward compatible with earlier Bently Nevada systems?

The 3300 XL 8mm probes are compatible with most existing 3300 Proximitor monitoring systems, ensuring backward integration.

5. What type of signal does the probe output?

The probe outputs a proportional voltage signal representing the shaft displacement or vibration amplitude.

6. How is the probe typically mounted on machinery?

It is installed in proximity to the shaft surface, usually in radial or axial measurement positions, using threaded mounting hardware.

7. What is the role of the probe within the overall monitoring system?

It forms the first sensing element, detecting shaft motion and transmitting data to the Proximitor and monitoring system.

8. How does cable length affect probe performance?

Cable length is factory-specified to maintain calibration. Deviating from standard lengths without recalibration may cause measurement errors.

9. Can this probe be used in hazardous or explosive environments?

Yes, with appropriate installation and certification, the probe can be deployed in hazardous areas, as it is designed for industrial compliance.

10. How does the probe ensure compliance with API 670 standards?

The probe meets requirements for accuracy, interchangeability, and reliability, fulfilling API 670 specifications for machinery protection.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...