Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

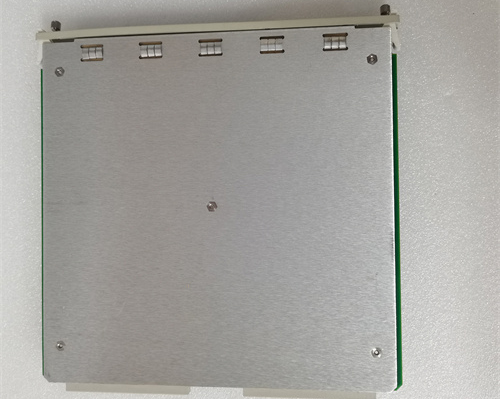

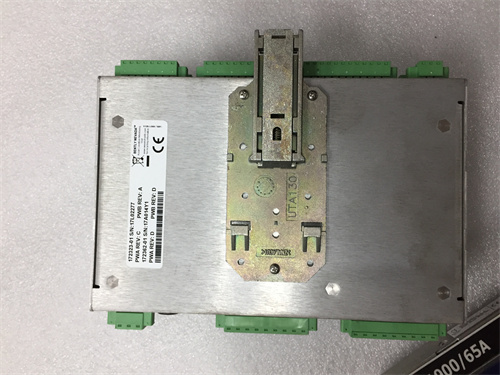

Bently Nevada 3500/42E 285691-01 Vibration Monitor

Manufacturer:Bently Nevada

Product Number:3500/42E 285691-01

Product Type:Vibration Monitor

Origin:USA

Dimensions:228 x 50 x 289 mm

Weight:1.27 kg

Views:37

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42E 285691-01 Vibration Monitor is a high-precision machinery protection and condition monitoring module, designed for continuous measurement of radial vibration, thrust position, and shaft vibration. As part of the proven 3500 series, it provides real-time monitoring, advanced alarm capabilities, and seamless integration with the 3500 rack system.

It is widely used in critical rotating machinery such as turbines, compressors, and pumps, where early fault detection can prevent costly downtime and equipment damage. The module combines reliability, flexibility, and high-performance data acquisition to ensure stable plant operations.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 3500/42E 285691-01 |

| Series | Bently Nevada 3500 Machinery Protection System |

| Measurement Types | Radial vibration, thrust position, shaft vibration |

| Channels | 2 or 4 channels |

| Supported Sensors | Proximity probes, velocity transducers, accelerometers |

| Signal Processing | True RMS and Peak detection, configurable filters |

| Frequency Response | 0.1 Hz to 10 kHz (sensor dependent) |

| Dynamic Range | > 80 dB |

| Sampling Rate | Up to 1024 samples per channel/sec |

| Alarm Types | Alert and Danger (programmable) |

| Outputs | 4–20 mA, relay contacts, buffered outputs |

| Communication | 3500 rack network interface |

| Operating Temperature | -30°C to +65°C |

| Power Supply | Via 3500 rack backplane |

| Dimensions | 228 x 50 x 289 mm |

| Weight | 1.27 kg |

| Mounting | Plug-in module for 3500 rack |

| Certifications | CE, CSA, ATEX, IECEx (depending on configuration) |

Product Applications

The 3500/42E is suitable for a variety of industrial machinery protection tasks, including:

-

Steam turbines – Rotor vibration monitoring for performance optimization and safety.

-

Gas turbines – Early detection of imbalance, misalignment, and bearing wear.

-

Compressors – Continuous shaft vibration measurement to avoid surge-related damage.

-

Pumps – Identification of cavitation and impeller faults.

-

Gearboxes – Detection of gear mesh defects and misalignment.

-

Fans & blowers – Ensuring smooth operation and preventing resonance issues.

Product Advantages

-

High accuracy in vibration measurement using advanced digital signal processing.

-

Flexible configuration to suit different machine types and sensor inputs.

-

Seamless integration with the Bently Nevada 3500 rack system.

-

Rugged design for reliable performance in harsh environments.

-

Programmable alarm thresholds for tailored machinery protection.

-

Supports both real-time monitoring and long-term trend analysis.

FAQ

-

What types of vibration can the 3500/42E measure?

It can measure radial vibration, thrust position, and shaft vibration depending on the connected sensor type.

-

Can it accept different sensor types?

Yes, it supports proximity probes, velocity transducers, and accelerometers for versatile monitoring.

-

Does the module provide both RMS and peak measurements?

Yes, it processes and displays both RMS and peak values for accurate vibration analysis.

-

How are alarms handled?

The module features two alarm levels—Alert and Danger—both of which are fully programmable.

-

Can data be accessed remotely?

Yes, through the 3500 rack’s communication interface, data can be monitored and retrieved remotely.

-

What is the purpose of the buffered output?

Buffered outputs allow portable analyzers to be connected without interrupting the monitoring system.

-

Is the module hot-swappable?

Yes, it can be removed or installed without shutting down the 3500 rack system.

-

How does it filter unwanted frequencies?

It uses configurable high-pass and low-pass filters to isolate relevant vibration frequency bands.

-

Is the module certified for hazardous locations?

Yes, with the correct configuration, it meets ATEX, IECEx, and CSA hazardous area certifications.

-

What is the maximum sampling rate?

It can sample up to 1024 samples per channel per second.

Bently Nevada 3500/42E 285691-01 Vibration Monitor

Manufacturer:Bently Nevada

Product Number:3500/42E 285691-01

Product Type:Vibration Monitor

Origin:USA

Dimensions:228 x 50 x 289 mm

Weight:1.27 kg

Views:37

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42E 285691-01 Vibration Monitor is a high-precision machinery protection and condition monitoring module, designed for continuous measurement of radial vibration, thrust position, and shaft vibration. As part of the proven 3500 series, it provides real-time monitoring, advanced alarm capabilities, and seamless integration with the 3500 rack system.

It is widely used in critical rotating machinery such as turbines, compressors, and pumps, where early fault detection can prevent costly downtime and equipment damage. The module combines reliability, flexibility, and high-performance data acquisition to ensure stable plant operations.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 3500/42E 285691-01 |

| Series | Bently Nevada 3500 Machinery Protection System |

| Measurement Types | Radial vibration, thrust position, shaft vibration |

| Channels | 2 or 4 channels |

| Supported Sensors | Proximity probes, velocity transducers, accelerometers |

| Signal Processing | True RMS and Peak detection, configurable filters |

| Frequency Response | 0.1 Hz to 10 kHz (sensor dependent) |

| Dynamic Range | > 80 dB |

| Sampling Rate | Up to 1024 samples per channel/sec |

| Alarm Types | Alert and Danger (programmable) |

| Outputs | 4–20 mA, relay contacts, buffered outputs |

| Communication | 3500 rack network interface |

| Operating Temperature | -30°C to +65°C |

| Power Supply | Via 3500 rack backplane |

| Dimensions | 228 x 50 x 289 mm |

| Weight | 1.27 kg |

| Mounting | Plug-in module for 3500 rack |

| Certifications | CE, CSA, ATEX, IECEx (depending on configuration) |

Product Applications

The 3500/42E is suitable for a variety of industrial machinery protection tasks, including:

-

Steam turbines – Rotor vibration monitoring for performance optimization and safety.

-

Gas turbines – Early detection of imbalance, misalignment, and bearing wear.

-

Compressors – Continuous shaft vibration measurement to avoid surge-related damage.

-

Pumps – Identification of cavitation and impeller faults.

-

Gearboxes – Detection of gear mesh defects and misalignment.

-

Fans & blowers – Ensuring smooth operation and preventing resonance issues.

Product Advantages

-

High accuracy in vibration measurement using advanced digital signal processing.

-

Flexible configuration to suit different machine types and sensor inputs.

-

Seamless integration with the Bently Nevada 3500 rack system.

-

Rugged design for reliable performance in harsh environments.

-

Programmable alarm thresholds for tailored machinery protection.

-

Supports both real-time monitoring and long-term trend analysis.

FAQ

-

What types of vibration can the 3500/42E measure?

It can measure radial vibration, thrust position, and shaft vibration depending on the connected sensor type.

-

Can it accept different sensor types?

Yes, it supports proximity probes, velocity transducers, and accelerometers for versatile monitoring.

-

Does the module provide both RMS and peak measurements?

Yes, it processes and displays both RMS and peak values for accurate vibration analysis.

-

How are alarms handled?

The module features two alarm levels—Alert and Danger—both of which are fully programmable.

-

Can data be accessed remotely?

Yes, through the 3500 rack’s communication interface, data can be monitored and retrieved remotely.

-

What is the purpose of the buffered output?

Buffered outputs allow portable analyzers to be connected without interrupting the monitoring system.

-

Is the module hot-swappable?

Yes, it can be removed or installed without shutting down the 3500 rack system.

-

How does it filter unwanted frequencies?

It uses configurable high-pass and low-pass filters to isolate relevant vibration frequency bands.

-

Is the module certified for hazardous locations?

Yes, with the correct configuration, it meets ATEX, IECEx, and CSA hazardous area certifications.

-

What is the maximum sampling rate?

It can sample up to 1024 samples per channel per second.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...