Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

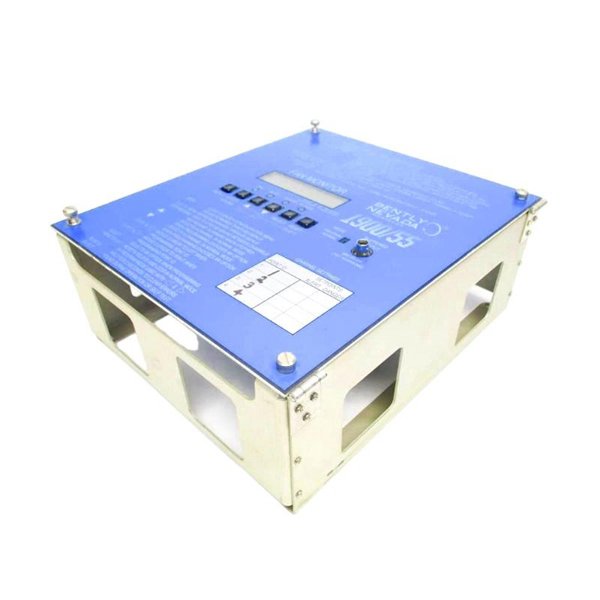

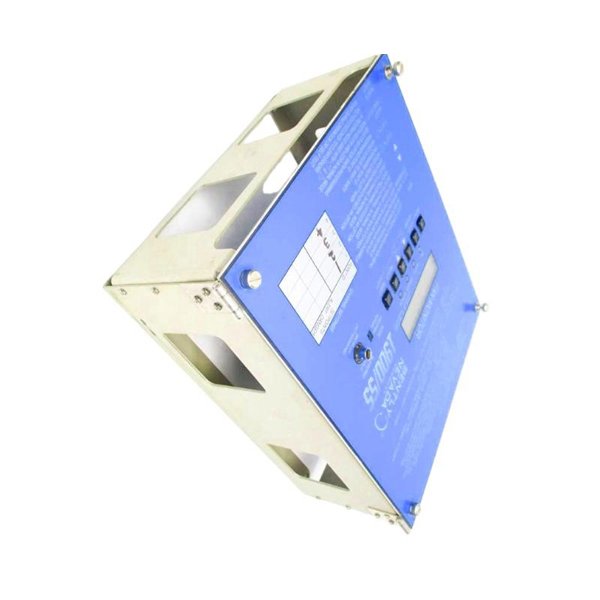

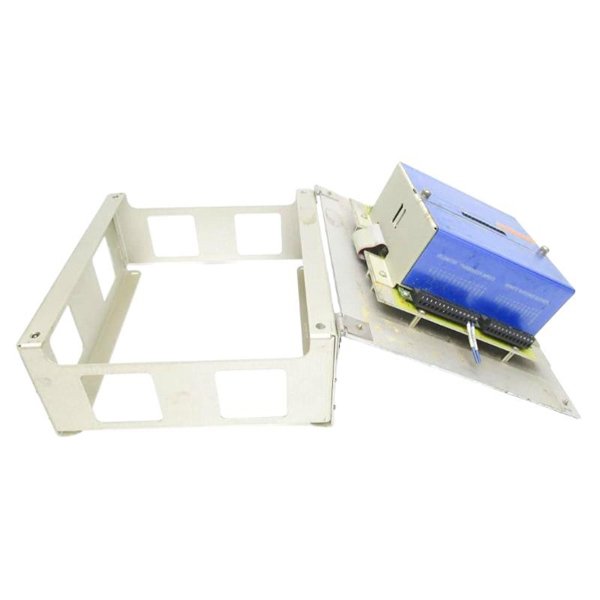

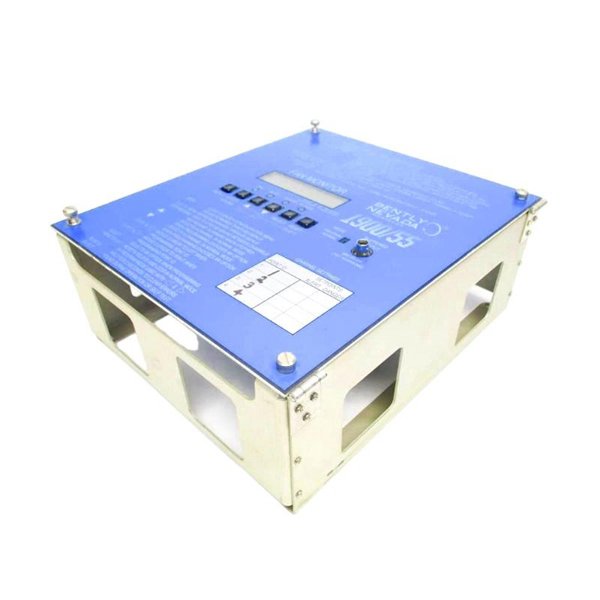

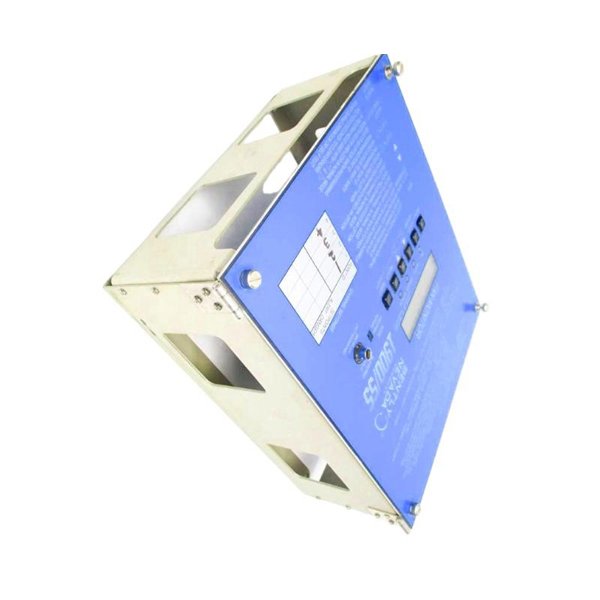

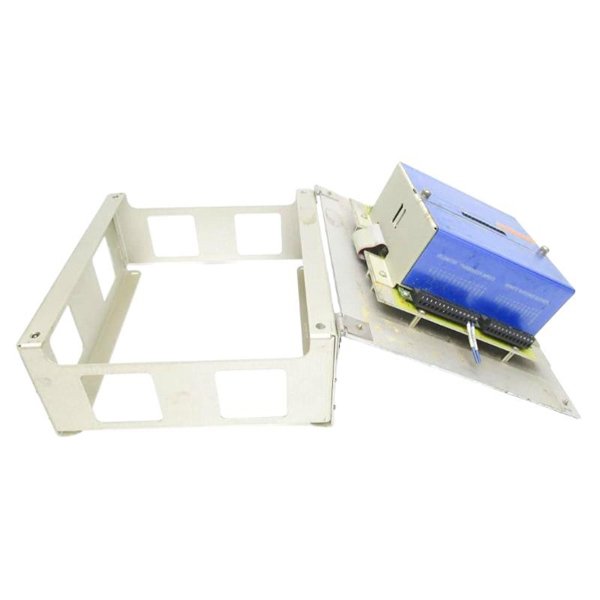

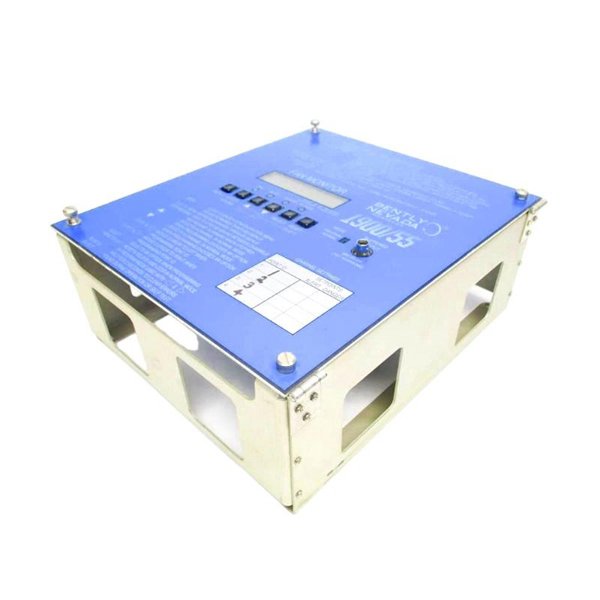

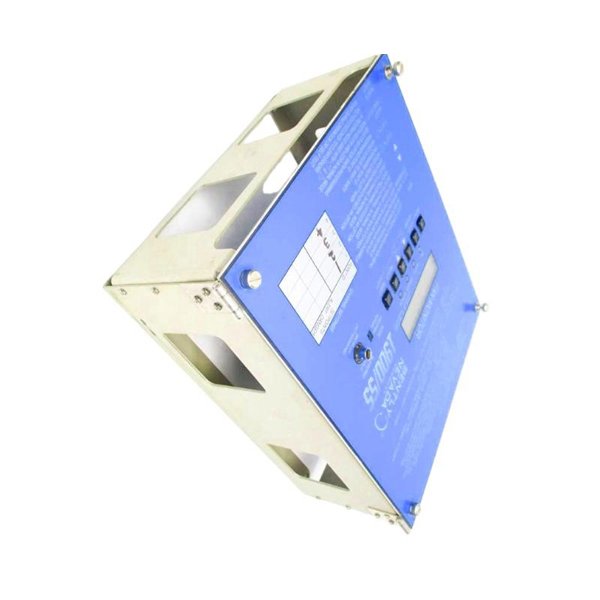

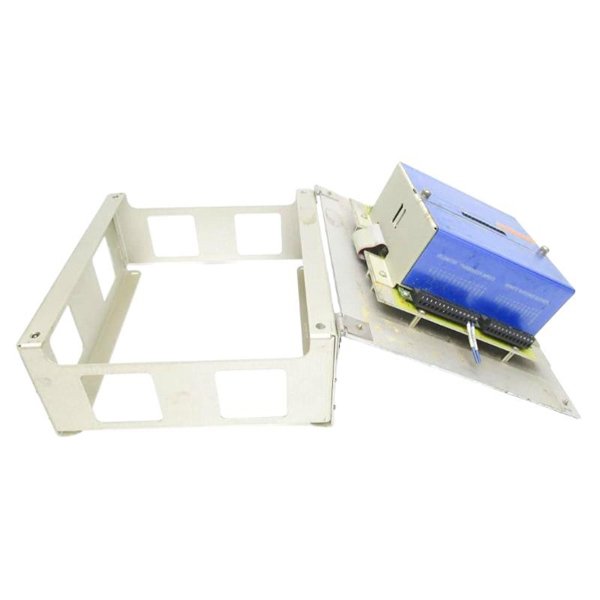

Bently Nevada 1900/55-01-01-01-00 Fan Monitor

Manufacturer:Bently Nevada

Product Number:1900/55-01-01-01-00

Product Type:Fan Monitor

Origin:USA

Dimensions:337 x 295 x 130 mm

Weight:3.18 kg

Views:34

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 1900/55-01-01-01-00 Fan Monitor is a dedicated vibration monitoring device designed for continuous condition monitoring of fans and blowers in industrial environments. It is part of the renowned Bently Nevada 1900 Series, specifically engineered for stand-alone protection of rotating machinery. This model delivers real-time vibration analysis to prevent unexpected failures, reduce downtime, and enhance machinery reliability.

The unit integrates with proximity probes or accelerometers to measure dynamic vibration levels and provides early detection of potential issues like unbalance, misalignment, looseness, and bearing degradation. It features configurable alarm thresholds, relay outputs for trip or warning conditions, and compatibility with Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC) for seamless integration into plant-wide monitoring systems.

Designed for harsh industrial conditions, the monitor withstands temperature extremes, vibration, and contamination such as dust and moisture. It is ideal for critical equipment where failure could result in costly shutdowns or safety hazards.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | Bently Nevada 1900/55-01-01-01-00 |

| Monitoring Function | Fan and blower vibration monitoring |

| Supported Sensors | Proximity probes (API 670 standard) and accelerometers |

| Measurement Range | 0–50 mm/s (velocity), 0–100 mils (displacement), configurable |

| Frequency Response | 10 Hz – 10 kHz |

| Input Channels | 2 channels (dynamic vibration input) |

| Output | 4–20 mA analog signal per channel |

| Alarm Outputs | 2 SPDT relays per channel (Alert and Danger) |

| Power Supply | 115/230 V AC ±10%, 50/60 Hz |

| Power Consumption | 10 W maximum |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -20°C to +70°C |

| Humidity | 5%–95% RH, non-condensing |

| Environmental Protection | IP55 enclosure rating |

| Communication Interface | Optional Modbus for system integration |

| Dimensions (H × W × D) | 337 x 295 x 130 mm |

| Weight | 3.18 kg |

| Certifications | CE, UL, CSA, IEC compliant |

Product Applications

The 1900/55-01-01-01-00 Fan Monitor is widely deployed across industries for reliable machinery protection and predictive maintenance. Common applications include:

-

Industrial Fans and Blowers: Continuous monitoring of vibration and detecting early mechanical issues.

-

Power Generation: Monitoring primary and auxiliary fans in thermal and nuclear plants.

-

Oil & Gas Facilities: Protection of ventilation fans in refineries and offshore platforms.

-

Petrochemical and Chemical Plants: Ensuring reliability of process-critical air handling equipment.

-

Manufacturing Plants: Monitoring exhaust and cooling fans for uninterrupted production.

-

HVAC Systems: Condition monitoring of high-capacity fans in commercial and industrial setups.

Product Advantages

-

Dedicated Fan Monitoring: Optimized for fan and blower vibration analysis, ensuring accurate diagnostics.

-

High Sensitivity: Detects minute changes in vibration patterns for early fault detection.

-

Rugged Design: Built for operation in harsh industrial conditions, with IP55-rated enclosure.

-

Seamless Integration: Outputs compatible with DCS and PLC systems for centralized monitoring.

-

Flexible Configuration: Adjustable alarm thresholds and frequency filters for specific applications.

-

Fail-Safe Design: Relay outputs for machine protection with alert and trip levels.

-

Wide Compatibility: Supports multiple sensor types for versatile installation.

-

Improved Reliability: Reduces unplanned downtime and maintenance costs through predictive maintenance.

Frequently Asked Questions (FAQ)

-

What type of sensors can be connected to this monitor?

It supports proximity probes (API 670 compliant) and accelerometers.

-

What is the number of input channels in this model?

The 1900/55-01-01-01-00 supports two dynamic vibration input channels.

-

What is the frequency range it can measure?

The monitor has a frequency response of 10 Hz to 10 kHz.

-

Can it provide both alert and danger alarms?

Yes, it has separate SPDT relays for alert and danger conditions on each channel.

-

Does the monitor offer an analog output signal?

Yes, it provides a 4–20 mA analog signal per channel for continuous monitoring.

-

Is there a digital communication option for integration?

Yes, Modbus communication is available for integration with control systems.

-

How are alarm thresholds configured?

Alarm thresholds can be set via local configuration for alert and danger limits.

-

Does this monitor support integration into PLC or DCS systems?

Yes, it supports both through analog outputs and optional Modbus connectivity.

-

What environmental protection does the enclosure provide?

It has an IP55-rated enclosure for protection against dust and moisture.

-

Is it suitable for continuous online monitoring?

Yes, the 1900/55 series is specifically designed for continuous online monitoring.

Bently Nevada 1900/55-01-01-01-00 Fan Monitor

Manufacturer:Bently Nevada

Product Number:1900/55-01-01-01-00

Product Type:Fan Monitor

Origin:USA

Dimensions:337 x 295 x 130 mm

Weight:3.18 kg

Views:34

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 1900/55-01-01-01-00 Fan Monitor is a dedicated vibration monitoring device designed for continuous condition monitoring of fans and blowers in industrial environments. It is part of the renowned Bently Nevada 1900 Series, specifically engineered for stand-alone protection of rotating machinery. This model delivers real-time vibration analysis to prevent unexpected failures, reduce downtime, and enhance machinery reliability.

The unit integrates with proximity probes or accelerometers to measure dynamic vibration levels and provides early detection of potential issues like unbalance, misalignment, looseness, and bearing degradation. It features configurable alarm thresholds, relay outputs for trip or warning conditions, and compatibility with Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC) for seamless integration into plant-wide monitoring systems.

Designed for harsh industrial conditions, the monitor withstands temperature extremes, vibration, and contamination such as dust and moisture. It is ideal for critical equipment where failure could result in costly shutdowns or safety hazards.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | Bently Nevada 1900/55-01-01-01-00 |

| Monitoring Function | Fan and blower vibration monitoring |

| Supported Sensors | Proximity probes (API 670 standard) and accelerometers |

| Measurement Range | 0–50 mm/s (velocity), 0–100 mils (displacement), configurable |

| Frequency Response | 10 Hz – 10 kHz |

| Input Channels | 2 channels (dynamic vibration input) |

| Output | 4–20 mA analog signal per channel |

| Alarm Outputs | 2 SPDT relays per channel (Alert and Danger) |

| Power Supply | 115/230 V AC ±10%, 50/60 Hz |

| Power Consumption | 10 W maximum |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -20°C to +70°C |

| Humidity | 5%–95% RH, non-condensing |

| Environmental Protection | IP55 enclosure rating |

| Communication Interface | Optional Modbus for system integration |

| Dimensions (H × W × D) | 337 x 295 x 130 mm |

| Weight | 3.18 kg |

| Certifications | CE, UL, CSA, IEC compliant |

Product Applications

The 1900/55-01-01-01-00 Fan Monitor is widely deployed across industries for reliable machinery protection and predictive maintenance. Common applications include:

-

Industrial Fans and Blowers: Continuous monitoring of vibration and detecting early mechanical issues.

-

Power Generation: Monitoring primary and auxiliary fans in thermal and nuclear plants.

-

Oil & Gas Facilities: Protection of ventilation fans in refineries and offshore platforms.

-

Petrochemical and Chemical Plants: Ensuring reliability of process-critical air handling equipment.

-

Manufacturing Plants: Monitoring exhaust and cooling fans for uninterrupted production.

-

HVAC Systems: Condition monitoring of high-capacity fans in commercial and industrial setups.

Product Advantages

-

Dedicated Fan Monitoring: Optimized for fan and blower vibration analysis, ensuring accurate diagnostics.

-

High Sensitivity: Detects minute changes in vibration patterns for early fault detection.

-

Rugged Design: Built for operation in harsh industrial conditions, with IP55-rated enclosure.

-

Seamless Integration: Outputs compatible with DCS and PLC systems for centralized monitoring.

-

Flexible Configuration: Adjustable alarm thresholds and frequency filters for specific applications.

-

Fail-Safe Design: Relay outputs for machine protection with alert and trip levels.

-

Wide Compatibility: Supports multiple sensor types for versatile installation.

-

Improved Reliability: Reduces unplanned downtime and maintenance costs through predictive maintenance.

Frequently Asked Questions (FAQ)

-

What type of sensors can be connected to this monitor?

It supports proximity probes (API 670 compliant) and accelerometers.

-

What is the number of input channels in this model?

The 1900/55-01-01-01-00 supports two dynamic vibration input channels.

-

What is the frequency range it can measure?

The monitor has a frequency response of 10 Hz to 10 kHz.

-

Can it provide both alert and danger alarms?

Yes, it has separate SPDT relays for alert and danger conditions on each channel.

-

Does the monitor offer an analog output signal?

Yes, it provides a 4–20 mA analog signal per channel for continuous monitoring.

-

Is there a digital communication option for integration?

Yes, Modbus communication is available for integration with control systems.

-

How are alarm thresholds configured?

Alarm thresholds can be set via local configuration for alert and danger limits.

-

Does this monitor support integration into PLC or DCS systems?

Yes, it supports both through analog outputs and optional Modbus connectivity.

-

What environmental protection does the enclosure provide?

It has an IP55-rated enclosure for protection against dust and moisture.

-

Is it suitable for continuous online monitoring?

Yes, the 1900/55 series is specifically designed for continuous online monitoring.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...