Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

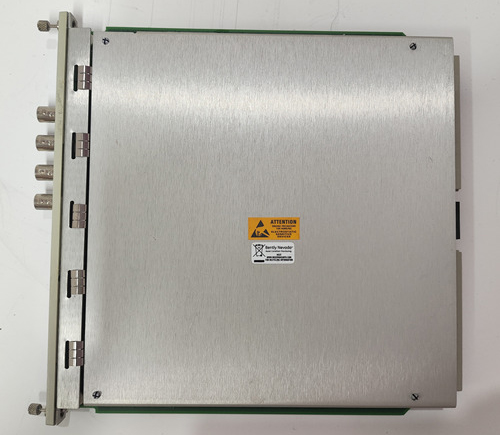

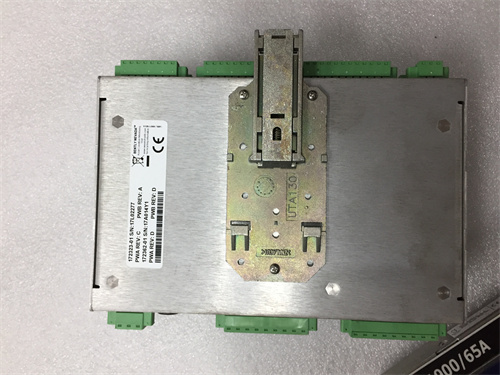

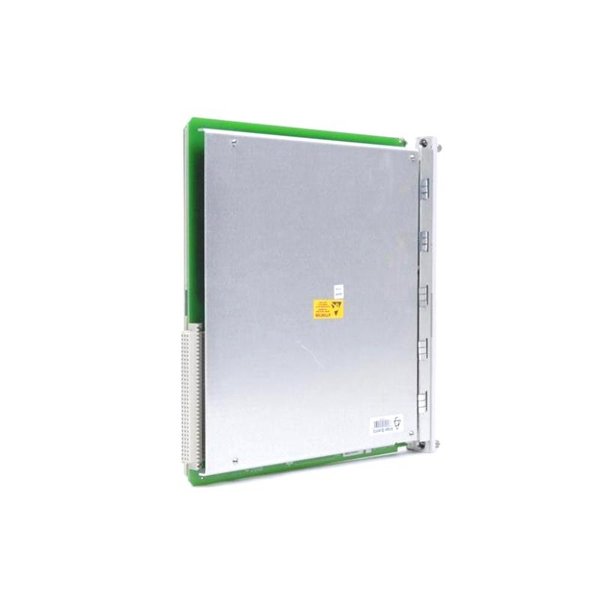

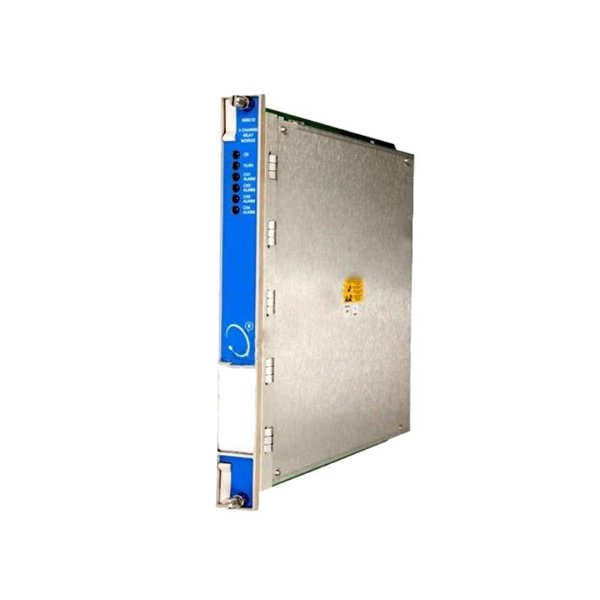

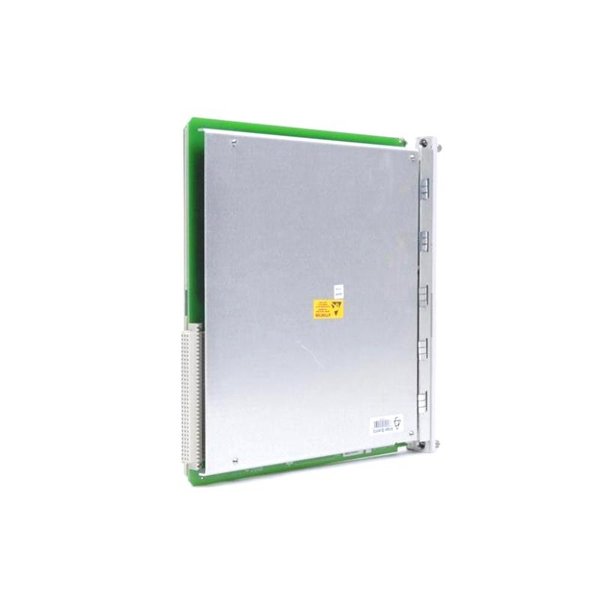

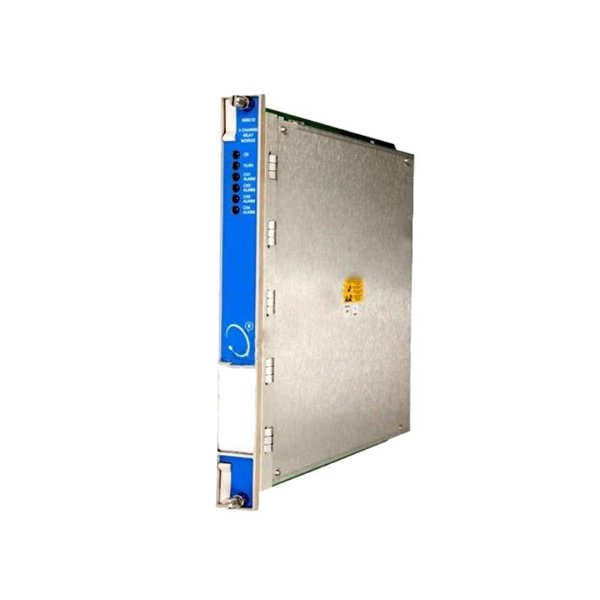

Bently Nevada 3500/32-01-00 4-Channel Relay Module

Manufacturer:Bently Nevada

Product Number:3500/32-01-00

Product Type:4-Channel Relay Module

Origin:USA

Dimensions:241 x 24.4 x 242 mm

Weight:0.7 kg

Views:93

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/32-01-00 is a high-reliability 4-Channel Relay Module, purpose-built to deliver alarm and shutdown logic in the 3500 Series Machinery Protection System. Acting as a critical interface between the monitoring system and external equipment, the module provides user-configurable relays that respond to system alarms, operating conditions, or user-defined logic.

Each relay channel is completely independent and software-configurable through the 3500 System Configuration Software. This module is essential for integrating machine protection functions with broader plant control systems such as Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), or Safety Instrumented Systems (SIS).

Product Specifications

| Parameter | Details |

| Model Number | 3500/32-01-00 |

| Description | 4-Channel Relay Module |

| Channels | 4 independent relays |

| Relay Type | Electromechanical SPDT (Single Pole Double Throw) relays |

| Contact Ratings | 5 A @ 24 VDC / 250 VAC resistive |

| Contact Life | 10⁶ operations minimum (resistive load) |

| Relay Energization | User-configurable (energized or de-energized) |

| Latch Functionality | Yes (software-configurable) |

| Alarm Conditions Supported | OK, NOT OK, ALERT, DANGER, System Events |

| Position in Rack | Requires adjacent Relay I/O Module in the rack |

| Power Consumption | < 6 Watts |

| Redundancy Support | Yes (in combination with dual modules) |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 0% to 95% RH, non-condensing |

| Certifications | CE, CSA, ATEX, IECEx, GOST |

| Dimensions (H × W × D) | 241 x 24.4 x 242 mm |

| Weight | 0.7 kg |

Product Applications

-

Turbomachinery Shutdown Systems: Provides critical trip outputs for steam turbines, gas turbines, and compressors.

-

Alarm Indication: Visual and audible alarms triggered through external devices via relays.

-

Process Automation Integration: Connects with DCS and SIS systems to share machine state and fault status.

-

Emergency Interlocks: Links machinery faults with plant-wide emergency shutdown sequences.

-

Industrial Machinery Protection: Commonly applied in oil & gas, petrochemical, power generation, and mining operations.

Product Advantages

-

Flexible Relay Configuration: Each relay channel can be individually assigned to specific alarms or logical conditions.

-

Failsafe Design: Supports both energized and de-energized relay operation for safety-critical systems.

-

High Endurance: Mechanical design ensures reliable performance across millions of operations.

-

Compact & Scalable: Slim profile integrates seamlessly into 3500 racks without consuming excess space.

-

Reliable Isolation: Electrical isolation between channels minimizes interference and cross-talk.

-

Logic-Driven Output: Can be tied to AND/OR logic in system configuration for advanced control strategies.

-

Redundant Operation: Works in redundant pairs to ensure continuous relay function during failures.

-

Certification Ready: Suitable for global installations including explosive and hazardous environments.

Frequently Asked Questions (FAQ)

-

What is the function of the 3500/32-01-00 Relay Module?

It outputs machine condition signals through relays, which can trigger alarms or shutdown commands.

-

How many relays are included in this module?

The module includes four independent electromechanical relays.

-

Can each relay be configured separately?

Yes, each channel can be assigned to specific conditions or logic operations.

-

Does it support redundant installation?

Yes, two 3500/32 modules can be configured for redundancy in critical systems.

-

What types of alarm conditions can it respond to?

OK, NOT OK, ALERT, DANGER, and custom system events.

-

Is the relay operation latched or non-latched?

Both are supported and configurable via software.

-

What’s the contact rating of each relay?

Each relay supports up to 5A at 24 VDC or 250 VAC resistive loads.

-

Can it operate in hazardous environments?

Yes, with certifications including ATEX, CSA, IECEx, and GOST.

-

How is the relay module powered?

Power is supplied directly from the 3500 rack.

-

Do I need an additional I/O module for relay connections?

Yes, the 3500/33 Relay I/O Module is used for external wiring access.

Bently Nevada 3500/32-01-00 4-Channel Relay Module

Manufacturer:Bently Nevada

Product Number:3500/32-01-00

Product Type:4-Channel Relay Module

Origin:USA

Dimensions:241 x 24.4 x 242 mm

Weight:0.7 kg

Views:93

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/32-01-00 is a high-reliability 4-Channel Relay Module, purpose-built to deliver alarm and shutdown logic in the 3500 Series Machinery Protection System. Acting as a critical interface between the monitoring system and external equipment, the module provides user-configurable relays that respond to system alarms, operating conditions, or user-defined logic.

Each relay channel is completely independent and software-configurable through the 3500 System Configuration Software. This module is essential for integrating machine protection functions with broader plant control systems such as Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), or Safety Instrumented Systems (SIS).

Product Specifications

| Parameter | Details |

| Model Number | 3500/32-01-00 |

| Description | 4-Channel Relay Module |

| Channels | 4 independent relays |

| Relay Type | Electromechanical SPDT (Single Pole Double Throw) relays |

| Contact Ratings | 5 A @ 24 VDC / 250 VAC resistive |

| Contact Life | 10⁶ operations minimum (resistive load) |

| Relay Energization | User-configurable (energized or de-energized) |

| Latch Functionality | Yes (software-configurable) |

| Alarm Conditions Supported | OK, NOT OK, ALERT, DANGER, System Events |

| Position in Rack | Requires adjacent Relay I/O Module in the rack |

| Power Consumption | < 6 Watts |

| Redundancy Support | Yes (in combination with dual modules) |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 0% to 95% RH, non-condensing |

| Certifications | CE, CSA, ATEX, IECEx, GOST |

| Dimensions (H × W × D) | 241 x 24.4 x 242 mm |

| Weight | 0.7 kg |

Product Applications

-

Turbomachinery Shutdown Systems: Provides critical trip outputs for steam turbines, gas turbines, and compressors.

-

Alarm Indication: Visual and audible alarms triggered through external devices via relays.

-

Process Automation Integration: Connects with DCS and SIS systems to share machine state and fault status.

-

Emergency Interlocks: Links machinery faults with plant-wide emergency shutdown sequences.

-

Industrial Machinery Protection: Commonly applied in oil & gas, petrochemical, power generation, and mining operations.

Product Advantages

-

Flexible Relay Configuration: Each relay channel can be individually assigned to specific alarms or logical conditions.

-

Failsafe Design: Supports both energized and de-energized relay operation for safety-critical systems.

-

High Endurance: Mechanical design ensures reliable performance across millions of operations.

-

Compact & Scalable: Slim profile integrates seamlessly into 3500 racks without consuming excess space.

-

Reliable Isolation: Electrical isolation between channels minimizes interference and cross-talk.

-

Logic-Driven Output: Can be tied to AND/OR logic in system configuration for advanced control strategies.

-

Redundant Operation: Works in redundant pairs to ensure continuous relay function during failures.

-

Certification Ready: Suitable for global installations including explosive and hazardous environments.

Frequently Asked Questions (FAQ)

-

What is the function of the 3500/32-01-00 Relay Module?

It outputs machine condition signals through relays, which can trigger alarms or shutdown commands.

-

How many relays are included in this module?

The module includes four independent electromechanical relays.

-

Can each relay be configured separately?

Yes, each channel can be assigned to specific conditions or logic operations.

-

Does it support redundant installation?

Yes, two 3500/32 modules can be configured for redundancy in critical systems.

-

What types of alarm conditions can it respond to?

OK, NOT OK, ALERT, DANGER, and custom system events.

-

Is the relay operation latched or non-latched?

Both are supported and configurable via software.

-

What’s the contact rating of each relay?

Each relay supports up to 5A at 24 VDC or 250 VAC resistive loads.

-

Can it operate in hazardous environments?

Yes, with certifications including ATEX, CSA, IECEx, and GOST.

-

How is the relay module powered?

Power is supplied directly from the 3500 rack.

-

Do I need an additional I/O module for relay connections?

Yes, the 3500/33 Relay I/O Module is used for external wiring access.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...