Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

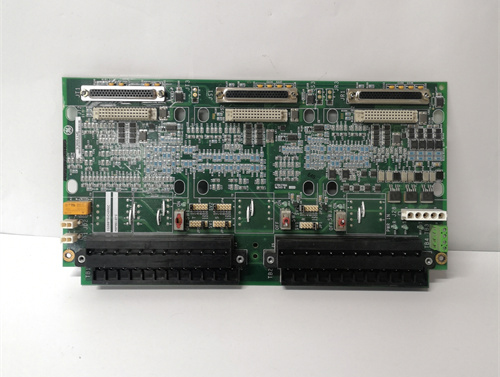

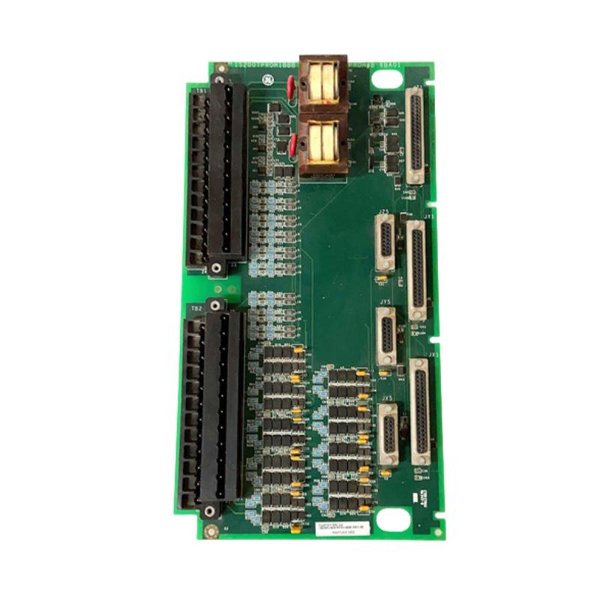

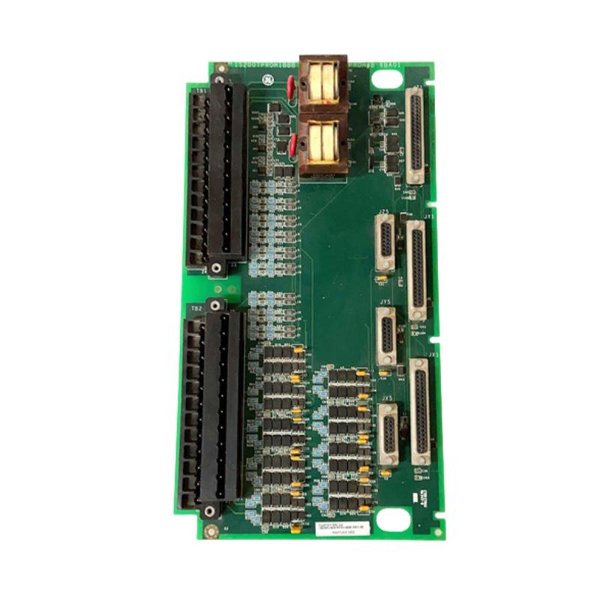

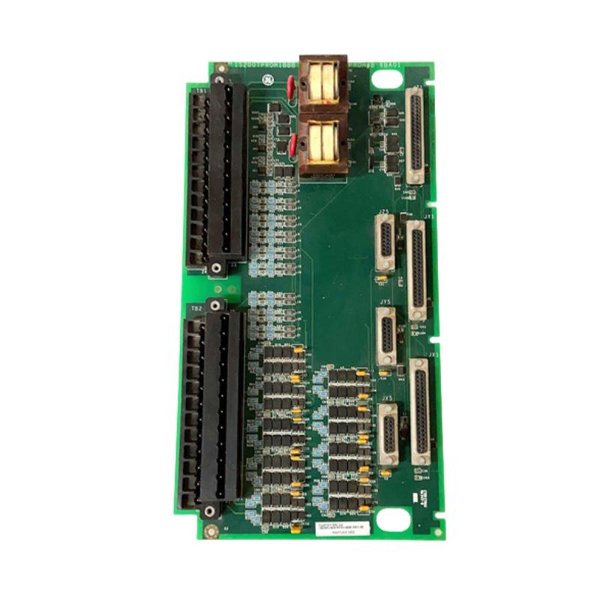

General Electric IS200TPROH1BBB Protective Termination Board

Manufacturer:GE

Product Number:IS200TPROH1BBB

Product Type:Protective Termination Board

Origin:USA

Dimensions:280 × 220 × 35 mm

Weight:0.4 kg

Views:23

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200TPROH1BBB Protective Termination Board is a critical component within the GE Mark VI and Mark VIe turbine control systems, specifically designed to interface protection circuits with control hardware. This board serves as a termination point for protective relay outputs, trip signals, and status feedback, ensuring accurate and secure signal transmission between the turbine protection devices and the control logic.

With its robust design, the IS200TPROH1BBB provides high-speed signal processing, fault isolation, and advanced relay management. It is widely used in gas and steam turbine systems, offering enhanced safety and reliability for mission-critical power generation applications. As part of GE’s Speedtronic family, this board is engineered to meet stringent industrial standards and ensure continuous turbine operation under demanding conditions.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IS200TPROH1BBB |

| Manufacturer | General Electric (GE) |

| Series | Mark VI / Mark VIe Control System |

| Function | Protective Termination Board |

| Power Supply | 28V DC nominal |

| Relay Outputs | 24 Form-C relays with independent supervision |

| Input Channels | Multiple turbine protection input signals supported |

| Isolation Voltage | 1500V RMS between control and field circuits |

| Communication Interface | Direct connection to Mark VI I/O cores |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% non-condensing |

| Mounting Type | Rack/Panel mounted |

| Compliance | CE, UL, RoHS |

| Dimensions (H×W×D) | 280 × 220 × 35 mm |

| Weight | 0.4 kg |

Product Applications

-

Gas Turbine Systems: Provides secure termination for trip and relay signals in high-speed gas turbine control.

-

Steam Turbine Protection: Interfaces protective relays and feedback devices with Mark VI/VIe control systems.

-

Industrial Power Generation: Ensures fault isolation and protection signal integrity in critical power plant operations.

-

Process Automation: Used in large-scale industrial plants requiring precise and safe protection circuitry.

-

Oil & Gas Industry: Offers reliable turbine protection interface for offshore and onshore energy applications.

Product Advantages

-

High Signal Integrity: Ensures accurate and interference-free signal transmission between protection devices and control hardware.

-

Advanced Fault Detection: Built-in supervision circuits for detecting open coils, shorts, and relay faults.

-

Seamless Integration: Fully compatible with GE Mark VI and Mark VIe control systems.

-

Robust Industrial Design: Withstands harsh operating environments, including high vibration and temperature variations.

-

Ease of Maintenance: Modular design simplifies troubleshooting and board replacement without extended downtime.

-

Enhanced Safety: Provides reliable turbine trip and fault interface, reducing the risk of equipment damage.

FAQ

-

What is the primary role of the IS200TPROH1BBB in the Mark VI control system?

It acts as the termination interface for turbine protective relays and trip circuits, ensuring secure and accurate signal processing.

-

How many relay outputs does the IS200TPROH1BBB support?

It supports 24 Form-C relay outputs with independent coil supervision.

-

Does the IS200TPROH1BBB provide electrical isolation between field and control sides?

Yes, it offers 1500V RMS isolation to safeguard control hardware from field disturbances.

-

Can this board be used in redundant protection configurations?

Yes, it supports redundant protection architectures within Mark VI/VIe systems.

-

What type of diagnostics are available on the IS200TPROH1BBB?

It includes built-in self-test circuits and LED indicators for relay and fault status monitoring.

-

Is the IS200TPROH1BBB compatible with both Mark VI and Mark VIe platforms?

Yes, it is designed to operate seamlessly with both Mark VI and Mark VIe systems.

-

How does the IS200TPROH1BBB handle trip signal integrity?

It uses shielded connections and integrated fault monitoring to ensure high integrity of trip signals.

-

What type of connectors are used for field wiring on this board?

It uses high-density terminal blocks to ensure stable and secure wiring connections.

-

Does the IS200TPROH1BBB support hot swapping during operation?

No, the system must be powered down before replacing the board to avoid operational interruptions.

-

What protective circuits are included on the IS200TPROH1BBB?

It includes surge suppression, isolation barriers, and relay coil supervision circuits to enhance protection reliability.

General Electric IS200TPROH1BBB Protective Termination Board

Manufacturer:GE

Product Number:IS200TPROH1BBB

Product Type:Protective Termination Board

Origin:USA

Dimensions:280 × 220 × 35 mm

Weight:0.4 kg

Views:23

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200TPROH1BBB Protective Termination Board is a critical component within the GE Mark VI and Mark VIe turbine control systems, specifically designed to interface protection circuits with control hardware. This board serves as a termination point for protective relay outputs, trip signals, and status feedback, ensuring accurate and secure signal transmission between the turbine protection devices and the control logic.

With its robust design, the IS200TPROH1BBB provides high-speed signal processing, fault isolation, and advanced relay management. It is widely used in gas and steam turbine systems, offering enhanced safety and reliability for mission-critical power generation applications. As part of GE’s Speedtronic family, this board is engineered to meet stringent industrial standards and ensure continuous turbine operation under demanding conditions.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IS200TPROH1BBB |

| Manufacturer | General Electric (GE) |

| Series | Mark VI / Mark VIe Control System |

| Function | Protective Termination Board |

| Power Supply | 28V DC nominal |

| Relay Outputs | 24 Form-C relays with independent supervision |

| Input Channels | Multiple turbine protection input signals supported |

| Isolation Voltage | 1500V RMS between control and field circuits |

| Communication Interface | Direct connection to Mark VI I/O cores |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% non-condensing |

| Mounting Type | Rack/Panel mounted |

| Compliance | CE, UL, RoHS |

| Dimensions (H×W×D) | 280 × 220 × 35 mm |

| Weight | 0.4 kg |

Product Applications

-

Gas Turbine Systems: Provides secure termination for trip and relay signals in high-speed gas turbine control.

-

Steam Turbine Protection: Interfaces protective relays and feedback devices with Mark VI/VIe control systems.

-

Industrial Power Generation: Ensures fault isolation and protection signal integrity in critical power plant operations.

-

Process Automation: Used in large-scale industrial plants requiring precise and safe protection circuitry.

-

Oil & Gas Industry: Offers reliable turbine protection interface for offshore and onshore energy applications.

Product Advantages

-

High Signal Integrity: Ensures accurate and interference-free signal transmission between protection devices and control hardware.

-

Advanced Fault Detection: Built-in supervision circuits for detecting open coils, shorts, and relay faults.

-

Seamless Integration: Fully compatible with GE Mark VI and Mark VIe control systems.

-

Robust Industrial Design: Withstands harsh operating environments, including high vibration and temperature variations.

-

Ease of Maintenance: Modular design simplifies troubleshooting and board replacement without extended downtime.

-

Enhanced Safety: Provides reliable turbine trip and fault interface, reducing the risk of equipment damage.

FAQ

-

What is the primary role of the IS200TPROH1BBB in the Mark VI control system?

It acts as the termination interface for turbine protective relays and trip circuits, ensuring secure and accurate signal processing.

-

How many relay outputs does the IS200TPROH1BBB support?

It supports 24 Form-C relay outputs with independent coil supervision.

-

Does the IS200TPROH1BBB provide electrical isolation between field and control sides?

Yes, it offers 1500V RMS isolation to safeguard control hardware from field disturbances.

-

Can this board be used in redundant protection configurations?

Yes, it supports redundant protection architectures within Mark VI/VIe systems.

-

What type of diagnostics are available on the IS200TPROH1BBB?

It includes built-in self-test circuits and LED indicators for relay and fault status monitoring.

-

Is the IS200TPROH1BBB compatible with both Mark VI and Mark VIe platforms?

Yes, it is designed to operate seamlessly with both Mark VI and Mark VIe systems.

-

How does the IS200TPROH1BBB handle trip signal integrity?

It uses shielded connections and integrated fault monitoring to ensure high integrity of trip signals.

-

What type of connectors are used for field wiring on this board?

It uses high-density terminal blocks to ensure stable and secure wiring connections.

-

Does the IS200TPROH1BBB support hot swapping during operation?

No, the system must be powered down before replacing the board to avoid operational interruptions.

-

What protective circuits are included on the IS200TPROH1BBB?

It includes surge suppression, isolation barriers, and relay coil supervision circuits to enhance protection reliability.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...