Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

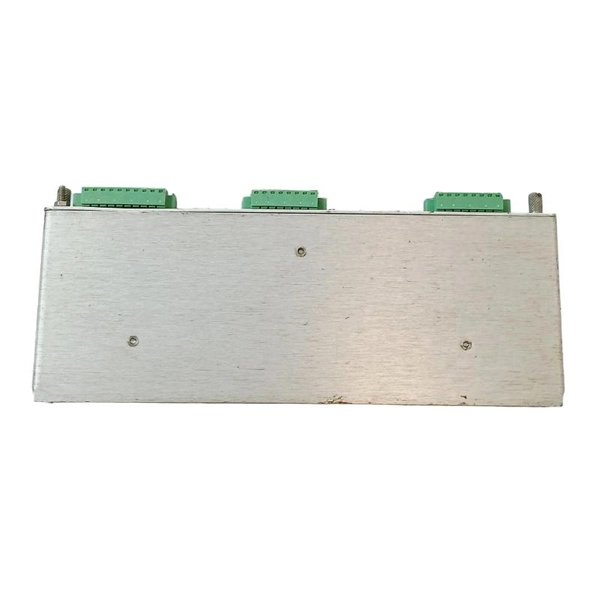

Bently Nevada 3500/42 176449-02+138708-01 Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42 176449-02+138708-01

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:37

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42 Proximitor Seismic Monitor (176449-02+138708-01) is a high-performance module designed for monitoring vibration and seismic activity in critical rotating machinery. Part of the 3500 Series, this module interfaces with AC Proximitor probes or seismic transducers to measure displacement, velocity, and vibration signals.

It supports dual or triple modular redundancy (TMR), ensuring continuous operation in safety-critical industrial systems. By providing precise real-time data on vibration and mechanical movement, the 3500/42 module helps detect early signs of mechanical issues such as imbalance, misalignment, looseness, or bearing wear, enabling proactive maintenance and preventing unplanned downtime.

This module is widely utilized in power generation, petrochemical, oil & gas, and other industries requiring reliable monitoring of high-value rotating equipment.

Product Parameters

| Parameter | Specification |

|---|---|

| Manufacturer | Bently Nevada |

| Model Number | 3500/42 |

| Part Number | 176449-02+138708-01 |

| Product Type | Proximitor Seismic Monitor |

| Architecture | Triple Modular Redundant (TMR) / Dual Redundant Option |

| Input Signals | AC signals from seismic or proximity sensors |

| Output Signals | Processed displacement, velocity, and vibration data |

| Number of Channels | 1–2 channels per module |

| Frequency Response | 0–5 kHz typical |

| Probe Excitation Voltage | 8–12 VDC |

| Signal Conditioning | Integrated amplification, filtering, and demodulation |

| LED Indicators | Channel status, fault, probe signal integrity |

| Mounting Type | Rack-mounted in 3500 Series chassis |

| Power Supply | 24 VDC via 3500 chassis backplane |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5%–95% non-condensing |

| Dimensions (W x H x D) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

Product Applications

The 3500/42 Seismic Monitor is designed for critical machinery vibration and seismic monitoring:

-

Turbine and Generator Monitoring – Detects axial, radial, and torsional vibrations for early fault identification.

-

Compressor & Pump Protection – Monitors for mechanical looseness, imbalance, and bearing degradation.

-

Industrial Equipment Monitoring – Ensures the safe operation of heavy rotating machinery in manufacturing plants.

-

Power Plants – Integrates with SCADA/DCS systems for real-time vibration monitoring.

-

Oil & Gas Facilities – Protects high-value rotating equipment from vibration-related failures.

-

Predictive Maintenance Programs – Enables trend analysis and condition-based maintenance with accurate seismic and vibration data.

Product Advantages

-

High-Fidelity Vibration Detection – Provides accurate displacement, velocity, and vibration measurements.

-

Redundant Operation – Supports TMR or dual redundancy for uninterrupted monitoring.

-

Real-Time Fault Detection – Monitors equipment behavior instantly to detect abnormal vibration patterns.

-

Integrated Signal Conditioning – Built-in filtering, amplification, and demodulation enhance signal quality.

-

Clear Diagnostic Indicators – LED indicators show channel health, probe integrity, and fault conditions.

-

Seamless Integration – Fully compatible with 3500 Series chassis and Bently Nevada AC Proximitor or seismic probes.

-

Industrial-Grade Reliability – Operates reliably under high vibration, EMI, and temperature fluctuations.

FAQ

1. What probes are compatible with this module?

It supports AC Proximitor probes and seismic transducers from Bently Nevada.

2. How many channels can the module support?

The module supports 1–2 channels depending on the configuration.

3. What is the frequency response range of the 3500/42?

The typical frequency response is 0–5 kHz.

4. Can this module operate in redundant configurations?

Yes, dual and triple modular redundant (TMR) configurations are supported.

5. Can the module interface with DCS or PLC systems?

Yes, processed outputs can be routed to SCADA, DCS, or PLC systems for real-time monitoring.

6. How are diagnostics displayed?

LED indicators show channel status, probe signal integrity, and fault conditions.

7. What is the probe excitation voltage?

The module provides 8–12 VDC excitation to the connected probes.

8. Is hot-swapping supported?

No, the module must be powered down before installation or removal.

9. What types of signals are output by the module?

It outputs processed displacement, velocity, and vibration signals.

10. Can it detect mechanical faults like imbalance or looseness?

Yes, continuous monitoring enables detection of misalignment, imbalance, looseness, and other mechanical issues.

Bently Nevada 3500/42 176449-02+138708-01 Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42 176449-02+138708-01

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:37

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42 Proximitor Seismic Monitor (176449-02+138708-01) is a high-performance module designed for monitoring vibration and seismic activity in critical rotating machinery. Part of the 3500 Series, this module interfaces with AC Proximitor probes or seismic transducers to measure displacement, velocity, and vibration signals.

It supports dual or triple modular redundancy (TMR), ensuring continuous operation in safety-critical industrial systems. By providing precise real-time data on vibration and mechanical movement, the 3500/42 module helps detect early signs of mechanical issues such as imbalance, misalignment, looseness, or bearing wear, enabling proactive maintenance and preventing unplanned downtime.

This module is widely utilized in power generation, petrochemical, oil & gas, and other industries requiring reliable monitoring of high-value rotating equipment.

Product Parameters

| Parameter | Specification |

|---|---|

| Manufacturer | Bently Nevada |

| Model Number | 3500/42 |

| Part Number | 176449-02+138708-01 |

| Product Type | Proximitor Seismic Monitor |

| Architecture | Triple Modular Redundant (TMR) / Dual Redundant Option |

| Input Signals | AC signals from seismic or proximity sensors |

| Output Signals | Processed displacement, velocity, and vibration data |

| Number of Channels | 1–2 channels per module |

| Frequency Response | 0–5 kHz typical |

| Probe Excitation Voltage | 8–12 VDC |

| Signal Conditioning | Integrated amplification, filtering, and demodulation |

| LED Indicators | Channel status, fault, probe signal integrity |

| Mounting Type | Rack-mounted in 3500 Series chassis |

| Power Supply | 24 VDC via 3500 chassis backplane |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5%–95% non-condensing |

| Dimensions (W x H x D) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

Product Applications

The 3500/42 Seismic Monitor is designed for critical machinery vibration and seismic monitoring:

-

Turbine and Generator Monitoring – Detects axial, radial, and torsional vibrations for early fault identification.

-

Compressor & Pump Protection – Monitors for mechanical looseness, imbalance, and bearing degradation.

-

Industrial Equipment Monitoring – Ensures the safe operation of heavy rotating machinery in manufacturing plants.

-

Power Plants – Integrates with SCADA/DCS systems for real-time vibration monitoring.

-

Oil & Gas Facilities – Protects high-value rotating equipment from vibration-related failures.

-

Predictive Maintenance Programs – Enables trend analysis and condition-based maintenance with accurate seismic and vibration data.

Product Advantages

-

High-Fidelity Vibration Detection – Provides accurate displacement, velocity, and vibration measurements.

-

Redundant Operation – Supports TMR or dual redundancy for uninterrupted monitoring.

-

Real-Time Fault Detection – Monitors equipment behavior instantly to detect abnormal vibration patterns.

-

Integrated Signal Conditioning – Built-in filtering, amplification, and demodulation enhance signal quality.

-

Clear Diagnostic Indicators – LED indicators show channel health, probe integrity, and fault conditions.

-

Seamless Integration – Fully compatible with 3500 Series chassis and Bently Nevada AC Proximitor or seismic probes.

-

Industrial-Grade Reliability – Operates reliably under high vibration, EMI, and temperature fluctuations.

FAQ

1. What probes are compatible with this module?

It supports AC Proximitor probes and seismic transducers from Bently Nevada.

2. How many channels can the module support?

The module supports 1–2 channels depending on the configuration.

3. What is the frequency response range of the 3500/42?

The typical frequency response is 0–5 kHz.

4. Can this module operate in redundant configurations?

Yes, dual and triple modular redundant (TMR) configurations are supported.

5. Can the module interface with DCS or PLC systems?

Yes, processed outputs can be routed to SCADA, DCS, or PLC systems for real-time monitoring.

6. How are diagnostics displayed?

LED indicators show channel status, probe signal integrity, and fault conditions.

7. What is the probe excitation voltage?

The module provides 8–12 VDC excitation to the connected probes.

8. Is hot-swapping supported?

No, the module must be powered down before installation or removal.

9. What types of signals are output by the module?

It outputs processed displacement, velocity, and vibration signals.

10. Can it detect mechanical faults like imbalance or looseness?

Yes, continuous monitoring enables detection of misalignment, imbalance, looseness, and other mechanical issues.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...