Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

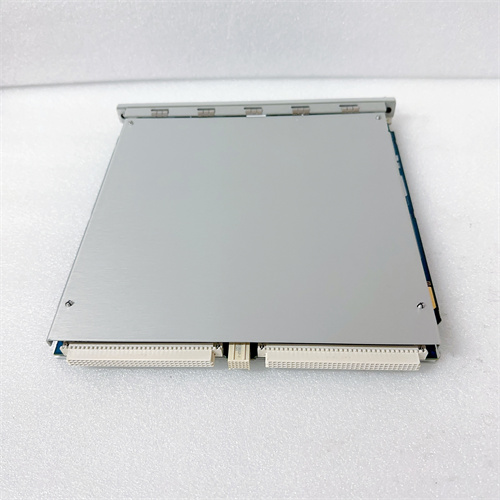

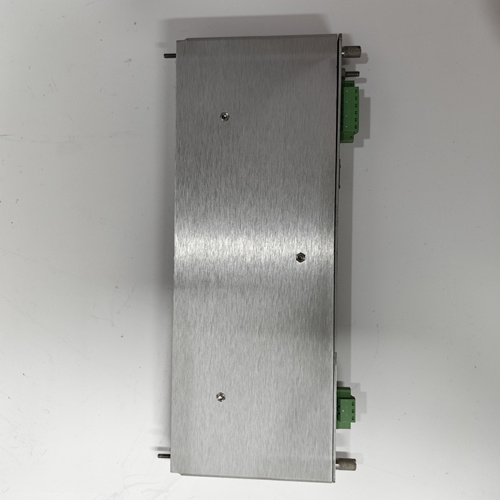

Bently Nevada 164517-090-05-01-00 3300 XL Ceramic Capped Proximity Probes

Manufacturer:Bently Nevada

Product Number:164517-090-05-01-00

Product Type:3300 XL Ceramic Capped Proximity Probes

Origin:USA

Total Length:0.5 meter

Weight:3 kg

Views:140

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 164517-090-05-01-00 3300 XL Ceramic Capped Proximity Probe is a high-performance sensing device designed for accurate measurement of shaft displacement and vibration in rotating machinery. As part of the 3300 XL series, it is widely used in industrial condition monitoring and machinery protection systems.

This model is equipped with a ceramic capped tip, which provides superior resistance against mechanical wear, chemical exposure, and high temperatures. By integrating advanced eddy-current sensing technology with rugged construction, the probe ensures precise, stable, and reliable measurements over extended operating cycles.

The 3300 XL series is renowned for its compatibility and long-term stability, making this probe a trusted choice in turbines, compressors, pumps, and other critical machinery across industries such as oil & gas, power generation, and heavy manufacturing.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 164517-090-05-01-00 |

| Type | 3300 XL Ceramic Capped Proximity Probe |

| Compatible Systems | Bently Nevada 3300 XL Monitoring Systems |

| Probe Tip Material | Ceramic |

| Housing Material | Stainless Steel |

| Measurement Technology | Eddy-current displacement sensing |

| Frequency Response | DC to 10 kHz (typical for XL series) |

| Operating Temperature Range | -40°C to +125°C |

| Environmental Resistance | Resistant to oils, coolants, and industrial chemicals |

| Mounting | Threaded housing for secure installation |

| Total Length | 0.5 meter |

| Shipping Weight | 3 kg |

Applications

The 164517-090-05-01-00 proximity probe is designed to support precise machinery diagnostics and long-term protection. Its typical applications include:

Steam and Gas Turbines: Continuous monitoring of shaft vibration and axial position to prevent catastrophic failure.

Compressors: Detecting rotor instability, imbalance, and surge conditions.

Pumps: Monitoring shaft displacement to identify misalignment or early bearing damage.

Motors and Generators: Providing predictive maintenance insights through shaft movement data.

Petrochemical Industry: Reliable in chemically aggressive environments due to ceramic and stainless-steel construction.

Industrial Condition Monitoring: Serving as a vital component of predictive maintenance systems and automatic shutdown logic.

Advantages

Ceramic Tip Durability: Offers superior wear resistance compared to standard probes, ensuring stable long-term measurements.

High Precision Measurement: Provides accurate shaft displacement data essential for machine protection and diagnostic systems.

Broad Environmental Compatibility: Resistant to oils, coolants, and aggressive chemicals found in industrial environments.

Temperature Resilience: Maintains performance over a wide temperature range, suitable for harsh operating conditions.

Reliable Integration: Fully compatible with Bently Nevada 3300 XL systems, enabling easy deployment without complex recalibration.

Enhanced Machine Protection: Ensures safe operation of critical machinery by enabling continuous monitoring and early detection of faults.

Reduced Maintenance Costs: Long-lasting construction minimizes downtime and replacement frequency.

FAQ

Which monitoring platforms support this probe?

It is designed for use with Bently Nevada 3300 XL series monitoring systems.

What sensing principle does this probe use?

It employs eddy-current displacement sensing technology to measure shaft vibration and position.

Does the ceramic tip affect signal sensitivity?

No, the ceramic tip preserves sensitivity while enhancing wear resistance and long-term measurement stability.

What is the probe’s frequency response range?

It typically responds from DC to 10 kHz, supporting accurate dynamic vibration measurement.

Can this probe withstand exposure to oil and industrial chemicals?

Yes, the ceramic tip and stainless-steel housing provide high resistance to such environments.

What is the main difference between ceramic capped and standard probes?

Ceramic capped probes offer longer service life and higher resistance to wear in harsh environments.

How does the probe handle high-vibration conditions?

It is specifically engineered for rotating machinery, ensuring stable operation in high-vibration applications.

Is the probe field-calibrated or factory-calibrated?

It is factory-calibrated, though system-level adjustments may be performed for optimal performance.

What shaft measurements can the probe provide?

It measures both radial vibration and shaft position (axial displacement) depending on installation.

Why is ceramic material important for proximity probes?

Ceramic prevents tip wear and degradation, allowing consistent eddy-current signal output over long-term use.

Bently Nevada 164517-090-05-01-00 3300 XL Ceramic Capped Proximity Probes

Manufacturer:Bently Nevada

Product Number:164517-090-05-01-00

Product Type:3300 XL Ceramic Capped Proximity Probes

Origin:USA

Total Length:0.5 meter

Weight:3 kg

Views:140

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 164517-090-05-01-00 3300 XL Ceramic Capped Proximity Probe is a high-performance sensing device designed for accurate measurement of shaft displacement and vibration in rotating machinery. As part of the 3300 XL series, it is widely used in industrial condition monitoring and machinery protection systems.

This model is equipped with a ceramic capped tip, which provides superior resistance against mechanical wear, chemical exposure, and high temperatures. By integrating advanced eddy-current sensing technology with rugged construction, the probe ensures precise, stable, and reliable measurements over extended operating cycles.

The 3300 XL series is renowned for its compatibility and long-term stability, making this probe a trusted choice in turbines, compressors, pumps, and other critical machinery across industries such as oil & gas, power generation, and heavy manufacturing.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 164517-090-05-01-00 |

| Type | 3300 XL Ceramic Capped Proximity Probe |

| Compatible Systems | Bently Nevada 3300 XL Monitoring Systems |

| Probe Tip Material | Ceramic |

| Housing Material | Stainless Steel |

| Measurement Technology | Eddy-current displacement sensing |

| Frequency Response | DC to 10 kHz (typical for XL series) |

| Operating Temperature Range | -40°C to +125°C |

| Environmental Resistance | Resistant to oils, coolants, and industrial chemicals |

| Mounting | Threaded housing for secure installation |

| Total Length | 0.5 meter |

| Shipping Weight | 3 kg |

Applications

The 164517-090-05-01-00 proximity probe is designed to support precise machinery diagnostics and long-term protection. Its typical applications include:

Steam and Gas Turbines: Continuous monitoring of shaft vibration and axial position to prevent catastrophic failure.

Compressors: Detecting rotor instability, imbalance, and surge conditions.

Pumps: Monitoring shaft displacement to identify misalignment or early bearing damage.

Motors and Generators: Providing predictive maintenance insights through shaft movement data.

Petrochemical Industry: Reliable in chemically aggressive environments due to ceramic and stainless-steel construction.

Industrial Condition Monitoring: Serving as a vital component of predictive maintenance systems and automatic shutdown logic.

Advantages

Ceramic Tip Durability: Offers superior wear resistance compared to standard probes, ensuring stable long-term measurements.

High Precision Measurement: Provides accurate shaft displacement data essential for machine protection and diagnostic systems.

Broad Environmental Compatibility: Resistant to oils, coolants, and aggressive chemicals found in industrial environments.

Temperature Resilience: Maintains performance over a wide temperature range, suitable for harsh operating conditions.

Reliable Integration: Fully compatible with Bently Nevada 3300 XL systems, enabling easy deployment without complex recalibration.

Enhanced Machine Protection: Ensures safe operation of critical machinery by enabling continuous monitoring and early detection of faults.

Reduced Maintenance Costs: Long-lasting construction minimizes downtime and replacement frequency.

FAQ

Which monitoring platforms support this probe?

It is designed for use with Bently Nevada 3300 XL series monitoring systems.

What sensing principle does this probe use?

It employs eddy-current displacement sensing technology to measure shaft vibration and position.

Does the ceramic tip affect signal sensitivity?

No, the ceramic tip preserves sensitivity while enhancing wear resistance and long-term measurement stability.

What is the probe’s frequency response range?

It typically responds from DC to 10 kHz, supporting accurate dynamic vibration measurement.

Can this probe withstand exposure to oil and industrial chemicals?

Yes, the ceramic tip and stainless-steel housing provide high resistance to such environments.

What is the main difference between ceramic capped and standard probes?

Ceramic capped probes offer longer service life and higher resistance to wear in harsh environments.

How does the probe handle high-vibration conditions?

It is specifically engineered for rotating machinery, ensuring stable operation in high-vibration applications.

Is the probe field-calibrated or factory-calibrated?

It is factory-calibrated, though system-level adjustments may be performed for optimal performance.

What shaft measurements can the probe provide?

It measures both radial vibration and shaft position (axial displacement) depending on installation.

Why is ceramic material important for proximity probes?

Ceramic prevents tip wear and degradation, allowing consistent eddy-current signal output over long-term use.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...