Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

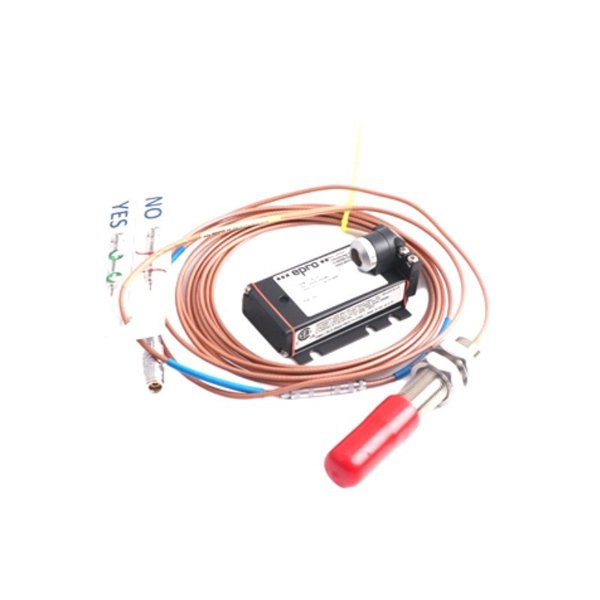

Epro PR6424/111-100 16mm Eddy Current Sensor

Manufacturer:Epro

Product Number:PR6424/111-100

Product Type:16mm Eddy Current Sensor

Origin:Germany

Sensor head diameter:16mm

Weight:0.2 kg

Views:87

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Epro PR6424/111-100 is a high-precision 16mm eddy current sensor designed for non-contact displacement and vibration measurement in demanding industrial environments. Operating on the eddy current principle, the sensor generates a magnetic field that induces circulating currents (eddy currents) in a conductive target. The sensor detects the variations in these currents to measure the distance between the sensor and the target, making it ideal for real-time monitoring of mechanical systems.

This sensor is widely used in condition monitoring, vibration analysis, position sensing, and displacement measurement in various industries such as automotive, aerospace, power generation, and manufacturing. With a robust design, high sensitivity, and non-contact measurement capabilities, the PR6424/111-100 is a versatile and reliable sensor for critical applications.

Product Specifications

| Feature | Specification |

|---|---|

| Sensor Type | Eddy Current Sensor |

| Sensing Head Diameter | 16 mm |

| Weight | 0.2 kg |

| Measurement Range | Up to 10 mm |

| Output Type | Analog or Digital (depending on model) |

| Temperature Range | -20°C to +80°C |

| Operating Frequency | High-frequency response |

| Power Supply | 15–30V DC |

| Accuracy | ±0.1% of full scale |

| Resolution | 0.01 mm |

| Material | Stainless steel, corrosion-resistant |

Applications

The Epro PR6424/111-100 eddy current sensor is designed for high-precision applications that require accurate, non-contact measurement. Key applications include:

Condition Monitoring: Used to monitor the health of rotating machinery such as motors, turbines, bearings, and pumps. The sensor helps identify early signs of wear, misalignment, and vibration issues, enabling preventive maintenance.

Vibration Measurement: Ideal for measuring vibration and displacement in rotating machinery. It is used to track the condition of compressors, pumps, and turbines in real-time, preventing potential failures.

Position Sensing: The sensor is used in position sensing applications, measuring the position of components like actuators, pistons, and sliders in automated systems, robotics, and assembly lines.

Non-Contact Measurement: The PR6424/111-100 enables non-contact measurement, making it ideal for high-speed applications and environments where contact-based sensors cannot be used.

Power Generation: The sensor is widely used in power plants for turbine monitoring, generator analysis, and other rotating machinery.

Automotive and Aerospace: In the automotive and aerospace industries, the sensor is used for inspection, alignment, and testing of critical components, ensuring proper performance and accuracy.

Product Advantages

Non-Contact Measurement: The PR6424/111-100 operates using eddy current technology, which eliminates the need for physical contact with the target. This prevents wear and ensures the sensor can measure at high speeds or in hazardous environments where contact sensors cannot be used.

High Precision: With ±0.1% accuracy and a resolution of 0.01 mm, the sensor delivers high-precision measurements, making it ideal for monitoring small displacements and vibrations.

Compact Design: The 16mm diameter sensing head is compact and lightweight, allowing it to be integrated into tight spaces without compromising on performance.

Robust and Durable: Built with stainless steel, the sensor is resistant to corrosion and can withstand harsh industrial environments, including exposure to oils, chemicals, and high temperatures.

High-Frequency Response: The sensor provides real-time dynamic measurement and high-frequency response, which makes it suitable for applications requiring high-speed data acquisition, such as vibration analysis and rotating machinery monitoring.

Versatile Output Options: The sensor supports both analog and digital outputs, providing flexibility for integration with various measurement systems, data acquisition platforms, and signal conditioners.

Wide Temperature Range: The PR6424/111-100 operates efficiently in temperatures ranging from -20°C to +80°C, making it suitable for a variety of environments from low-temperature to high-temperature industrial applications.

Energy-Efficient: The sensor requires a low power supply (15-30V DC), making it an energy-efficient option for continuous operation in large systems.

Long-Term Stability: Known for its stability, the PR6424/111-100 provides reliable long-term measurements without the need for frequent recalibration or maintenance.

Cost-Effective: Offering high performance at an affordable price, the PR6424/111-100 is a cost-effective solution for industrial vibration monitoring, displacement measurement, and condition monitoring.

FAQ

1. How does the Epro PR6424/111-100 sensor work?

The sensor operates using the eddy current principle, where it generates a magnetic field that induces currents in the conductive material of the target. Variations in these currents are detected, allowing the sensor to measure the distance between the sensor and the target.

2. What type of output does the sensor provide?

The PR6424/111-100 offers both analog and digital outputs, which makes it compatible with various data acquisition systems and monitoring platforms.

3. What is the accuracy of the sensor?

The PR6424/111-100 provides ±0.1% accuracy of the full-scale range, offering precise measurements suitable for sensitive applications.

4. Can the sensor measure vibration?

Yes, the PR6424/111-100 is ideal for measuring vibration and displacement in rotating machinery, such as turbines, pumps, and compressors.

5. What is the temperature range of the sensor?

The PR6424/111-100 operates within a temperature range of -20°C to +80°C, making it suitable for a wide range of industrial applications.

6. How does the sensor detect non-contact displacement?

The sensor generates a magnetic field that induces eddy currents in a conductive target. By detecting changes in these currents, the sensor can measure the displacement without making physical contact with the target.

7. What industries use the PR6424/111-100 sensor?

The sensor is used in various industries such as automotive, aerospace, power generation, manufacturing, and oil and gas for applications such as condition monitoring, vibration analysis, and position sensing.

8. Can the sensor be used in hazardous environments?

Yes, the PR6424/111-100 is ideal for hazardous environments due to its non-contact measurement capabilities, making it suitable for high-speed and challenging applications.

9. What is the measurement range of the sensor?

The PR6424/111-100 has a measurement range of up to 10 mm, making it suitable for applications that require precise measurement of small displacements and vibrations.

10. Is the sensor suitable for integration with data acquisition systems?

Yes, the sensor supports analog and digital outputs, enabling easy integration with data acquisition systems, signal conditioners, and monitoring platforms for real-time data collection and analysis.

Epro PR6424/111-100 16mm Eddy Current Sensor

Manufacturer:Epro

Product Number:PR6424/111-100

Product Type:16mm Eddy Current Sensor

Origin:Germany

Sensor head diameter:16mm

Weight:0.2 kg

Views:87

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Epro PR6424/111-100 is a high-precision 16mm eddy current sensor designed for non-contact displacement and vibration measurement in demanding industrial environments. Operating on the eddy current principle, the sensor generates a magnetic field that induces circulating currents (eddy currents) in a conductive target. The sensor detects the variations in these currents to measure the distance between the sensor and the target, making it ideal for real-time monitoring of mechanical systems.

This sensor is widely used in condition monitoring, vibration analysis, position sensing, and displacement measurement in various industries such as automotive, aerospace, power generation, and manufacturing. With a robust design, high sensitivity, and non-contact measurement capabilities, the PR6424/111-100 is a versatile and reliable sensor for critical applications.

Product Specifications

| Feature | Specification |

|---|---|

| Sensor Type | Eddy Current Sensor |

| Sensing Head Diameter | 16 mm |

| Weight | 0.2 kg |

| Measurement Range | Up to 10 mm |

| Output Type | Analog or Digital (depending on model) |

| Temperature Range | -20°C to +80°C |

| Operating Frequency | High-frequency response |

| Power Supply | 15–30V DC |

| Accuracy | ±0.1% of full scale |

| Resolution | 0.01 mm |

| Material | Stainless steel, corrosion-resistant |

Applications

The Epro PR6424/111-100 eddy current sensor is designed for high-precision applications that require accurate, non-contact measurement. Key applications include:

Condition Monitoring: Used to monitor the health of rotating machinery such as motors, turbines, bearings, and pumps. The sensor helps identify early signs of wear, misalignment, and vibration issues, enabling preventive maintenance.

Vibration Measurement: Ideal for measuring vibration and displacement in rotating machinery. It is used to track the condition of compressors, pumps, and turbines in real-time, preventing potential failures.

Position Sensing: The sensor is used in position sensing applications, measuring the position of components like actuators, pistons, and sliders in automated systems, robotics, and assembly lines.

Non-Contact Measurement: The PR6424/111-100 enables non-contact measurement, making it ideal for high-speed applications and environments where contact-based sensors cannot be used.

Power Generation: The sensor is widely used in power plants for turbine monitoring, generator analysis, and other rotating machinery.

Automotive and Aerospace: In the automotive and aerospace industries, the sensor is used for inspection, alignment, and testing of critical components, ensuring proper performance and accuracy.

Product Advantages

Non-Contact Measurement: The PR6424/111-100 operates using eddy current technology, which eliminates the need for physical contact with the target. This prevents wear and ensures the sensor can measure at high speeds or in hazardous environments where contact sensors cannot be used.

High Precision: With ±0.1% accuracy and a resolution of 0.01 mm, the sensor delivers high-precision measurements, making it ideal for monitoring small displacements and vibrations.

Compact Design: The 16mm diameter sensing head is compact and lightweight, allowing it to be integrated into tight spaces without compromising on performance.

Robust and Durable: Built with stainless steel, the sensor is resistant to corrosion and can withstand harsh industrial environments, including exposure to oils, chemicals, and high temperatures.

High-Frequency Response: The sensor provides real-time dynamic measurement and high-frequency response, which makes it suitable for applications requiring high-speed data acquisition, such as vibration analysis and rotating machinery monitoring.

Versatile Output Options: The sensor supports both analog and digital outputs, providing flexibility for integration with various measurement systems, data acquisition platforms, and signal conditioners.

Wide Temperature Range: The PR6424/111-100 operates efficiently in temperatures ranging from -20°C to +80°C, making it suitable for a variety of environments from low-temperature to high-temperature industrial applications.

Energy-Efficient: The sensor requires a low power supply (15-30V DC), making it an energy-efficient option for continuous operation in large systems.

Long-Term Stability: Known for its stability, the PR6424/111-100 provides reliable long-term measurements without the need for frequent recalibration or maintenance.

Cost-Effective: Offering high performance at an affordable price, the PR6424/111-100 is a cost-effective solution for industrial vibration monitoring, displacement measurement, and condition monitoring.

FAQ

1. How does the Epro PR6424/111-100 sensor work?

The sensor operates using the eddy current principle, where it generates a magnetic field that induces currents in the conductive material of the target. Variations in these currents are detected, allowing the sensor to measure the distance between the sensor and the target.

2. What type of output does the sensor provide?

The PR6424/111-100 offers both analog and digital outputs, which makes it compatible with various data acquisition systems and monitoring platforms.

3. What is the accuracy of the sensor?

The PR6424/111-100 provides ±0.1% accuracy of the full-scale range, offering precise measurements suitable for sensitive applications.

4. Can the sensor measure vibration?

Yes, the PR6424/111-100 is ideal for measuring vibration and displacement in rotating machinery, such as turbines, pumps, and compressors.

5. What is the temperature range of the sensor?

The PR6424/111-100 operates within a temperature range of -20°C to +80°C, making it suitable for a wide range of industrial applications.

6. How does the sensor detect non-contact displacement?

The sensor generates a magnetic field that induces eddy currents in a conductive target. By detecting changes in these currents, the sensor can measure the displacement without making physical contact with the target.

7. What industries use the PR6424/111-100 sensor?

The sensor is used in various industries such as automotive, aerospace, power generation, manufacturing, and oil and gas for applications such as condition monitoring, vibration analysis, and position sensing.

8. Can the sensor be used in hazardous environments?

Yes, the PR6424/111-100 is ideal for hazardous environments due to its non-contact measurement capabilities, making it suitable for high-speed and challenging applications.

9. What is the measurement range of the sensor?

The PR6424/111-100 has a measurement range of up to 10 mm, making it suitable for applications that require precise measurement of small displacements and vibrations.

10. Is the sensor suitable for integration with data acquisition systems?

Yes, the sensor supports analog and digital outputs, enabling easy integration with data acquisition systems, signal conditioners, and monitoring platforms for real-time data collection and analysis.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...