Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

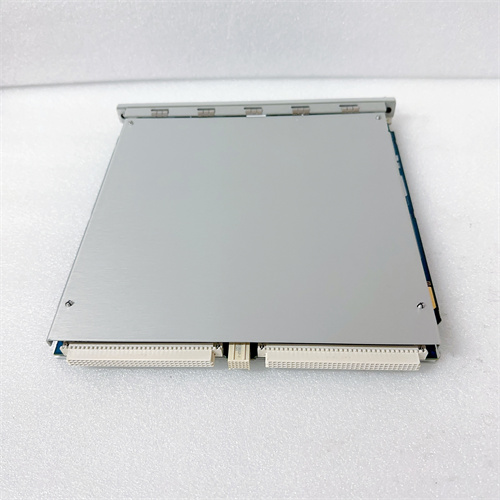

Bently Nevada 330106-05-30-15-02-05 3300 XL 8 mm Reverse Mount Probes

Manufacturer:Bently Nevada

Product Number:330106-05-30-15-02-05

Product Type:3300 XL 8 mm Reverse Mount Probes

Origin:USA

Total Length:1.5 meters

Weight:0.485 kg

Views:140

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330106-05-30-15-02-05 3300 XL 8 mm Reverse Mount Probe is a high-precision proximity probe engineered for critical machinery monitoring in industrial environments. As part of the 3300 XL series, this probe is designed for applications requiring reverse mounting in restricted spaces, allowing flexible installation without compromising measurement accuracy.

The 8 mm probe tip provides precise radial displacement and vibration detection, making it suitable for high-speed rotating machinery such as turbines, compressors, generators, and pumps. Its robust construction ensures reliable operation in extreme temperatures, high vibration, and humid conditions. When paired with Bently Nevada 3300 XL monitoring systems, it enables predictive maintenance, early fault detection, and enhanced operational safety.

This probe is particularly suited for installations where longer reach is required, as its 1.5-meter total length allows it to monitor shaft movement while remaining securely mounted in confined or challenging locations.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | 330106-05-30-15-02-05 |

| Series | 3300 XL |

| Probe Type | Reverse mount proximity probe |

| Probe Tip Diameter | 8 mm |

| Measurement Range | ±0.25 mm typical displacement |

| Total Length | 1.5 meters |

| Weight | 0.485 kg |

| Sensor Type | Eddy current |

| Mounting Style | Reverse mount |

| Connector | Integral cable with 4-pin MIL-style connector |

| Operating Temperature | -40°C to +120°C (-40°F to +248°F) |

| Humidity | 0–95% RH, non-condensing |

| Frequency Response | DC to 20 kHz typical |

| Material | Stainless steel probe body, ceramic tip |

| Maximum Shaft Speed | Up to 60,000 RPM (application dependent) |

| Certifications | CE, UL, CSA compliant |

Applications

The 3300 XL 8 mm Reverse Mount Probe is used in industrial machinery monitoring for high-reliability applications:

Steam and Gas Turbines: Provides shaft vibration and radial displacement measurements for high-speed rotors.

Compressors: Monitors centrifugal and axial compressors to detect imbalance or misalignment.

Generators: Measures shaft position and vibration to ensure rotor alignment and operational safety.

Industrial Pumps: Continuous monitoring to prevent mechanical wear or misalignment.

Power Plants: Ensures reliable operation of critical rotating machinery such as turbines, motors, and pumps.

Petrochemical and Oil & Gas Facilities: Ideal for installations with limited space requiring reverse mount configuration.

Advantages

The 3300 XL 8 mm Reverse Mount Probe provides multiple operational benefits:

High Measurement Accuracy: Precisely monitors radial shaft displacement and vibration.

Reverse Mount Capability: Suitable for restricted or non-standard installation spaces.

Robust Construction: Stainless steel body and ceramic tip provide durability in harsh environments.

High-Frequency Response: Effective for high-speed machinery with vibration frequencies up to 20 kHz.

Seamless Integration: Compatible with 3300 XL monitoring systems for accurate signal acquisition.

Extended Cable Length: 1.5-meter cable allows flexible placement without additional extensions.

Wide Operating Range: Reliable operation from -40°C to +120°C with high humidity tolerance.

Certified Compliance: CE, UL, and CSA certified for global industrial applications.

FAQ

What type of measurement does the 3300 XL 8 mm reverse mount probe provide?

It measures radial shaft displacement and vibration using eddy current technology.

What is the maximum shaft speed this probe can monitor?

Suitable for shafts up to 60,000 RPM depending on system configuration.

Can the probe be installed in reverse mount applications?

Yes, it is specifically designed for reverse mount installations in confined spaces.

What type of connector does the probe use for system integration?

Integral 4-pin MIL-style connector compatible with 3300 XL monitoring modules.

What is the frequency response of the probe?

DC to 20 kHz, suitable for high-speed machinery.

What is the operational temperature range of the probe?

-40°C to +120°C (-40°F to +248°F).

Can the probe operate reliably in humid environments?

Yes, it supports 0–95% relative humidity, non-condensing.

What is the measurement range of the probe?

±0.25 mm typical displacement.

Is the probe compatible with other 3300 XL system modules?

Yes, it fully integrates with all 3300 XL monitoring modules.

What materials are used for the probe body and tip?

Stainless steel body for durability and ceramic tip for wear resistance and stable measurements.

Bently Nevada 330106-05-30-15-02-05 3300 XL 8 mm Reverse Mount Probes

Manufacturer:Bently Nevada

Product Number:330106-05-30-15-02-05

Product Type:3300 XL 8 mm Reverse Mount Probes

Origin:USA

Total Length:1.5 meters

Weight:0.485 kg

Views:140

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330106-05-30-15-02-05 3300 XL 8 mm Reverse Mount Probe is a high-precision proximity probe engineered for critical machinery monitoring in industrial environments. As part of the 3300 XL series, this probe is designed for applications requiring reverse mounting in restricted spaces, allowing flexible installation without compromising measurement accuracy.

The 8 mm probe tip provides precise radial displacement and vibration detection, making it suitable for high-speed rotating machinery such as turbines, compressors, generators, and pumps. Its robust construction ensures reliable operation in extreme temperatures, high vibration, and humid conditions. When paired with Bently Nevada 3300 XL monitoring systems, it enables predictive maintenance, early fault detection, and enhanced operational safety.

This probe is particularly suited for installations where longer reach is required, as its 1.5-meter total length allows it to monitor shaft movement while remaining securely mounted in confined or challenging locations.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | 330106-05-30-15-02-05 |

| Series | 3300 XL |

| Probe Type | Reverse mount proximity probe |

| Probe Tip Diameter | 8 mm |

| Measurement Range | ±0.25 mm typical displacement |

| Total Length | 1.5 meters |

| Weight | 0.485 kg |

| Sensor Type | Eddy current |

| Mounting Style | Reverse mount |

| Connector | Integral cable with 4-pin MIL-style connector |

| Operating Temperature | -40°C to +120°C (-40°F to +248°F) |

| Humidity | 0–95% RH, non-condensing |

| Frequency Response | DC to 20 kHz typical |

| Material | Stainless steel probe body, ceramic tip |

| Maximum Shaft Speed | Up to 60,000 RPM (application dependent) |

| Certifications | CE, UL, CSA compliant |

Applications

The 3300 XL 8 mm Reverse Mount Probe is used in industrial machinery monitoring for high-reliability applications:

Steam and Gas Turbines: Provides shaft vibration and radial displacement measurements for high-speed rotors.

Compressors: Monitors centrifugal and axial compressors to detect imbalance or misalignment.

Generators: Measures shaft position and vibration to ensure rotor alignment and operational safety.

Industrial Pumps: Continuous monitoring to prevent mechanical wear or misalignment.

Power Plants: Ensures reliable operation of critical rotating machinery such as turbines, motors, and pumps.

Petrochemical and Oil & Gas Facilities: Ideal for installations with limited space requiring reverse mount configuration.

Advantages

The 3300 XL 8 mm Reverse Mount Probe provides multiple operational benefits:

High Measurement Accuracy: Precisely monitors radial shaft displacement and vibration.

Reverse Mount Capability: Suitable for restricted or non-standard installation spaces.

Robust Construction: Stainless steel body and ceramic tip provide durability in harsh environments.

High-Frequency Response: Effective for high-speed machinery with vibration frequencies up to 20 kHz.

Seamless Integration: Compatible with 3300 XL monitoring systems for accurate signal acquisition.

Extended Cable Length: 1.5-meter cable allows flexible placement without additional extensions.

Wide Operating Range: Reliable operation from -40°C to +120°C with high humidity tolerance.

Certified Compliance: CE, UL, and CSA certified for global industrial applications.

FAQ

What type of measurement does the 3300 XL 8 mm reverse mount probe provide?

It measures radial shaft displacement and vibration using eddy current technology.

What is the maximum shaft speed this probe can monitor?

Suitable for shafts up to 60,000 RPM depending on system configuration.

Can the probe be installed in reverse mount applications?

Yes, it is specifically designed for reverse mount installations in confined spaces.

What type of connector does the probe use for system integration?

Integral 4-pin MIL-style connector compatible with 3300 XL monitoring modules.

What is the frequency response of the probe?

DC to 20 kHz, suitable for high-speed machinery.

What is the operational temperature range of the probe?

-40°C to +120°C (-40°F to +248°F).

Can the probe operate reliably in humid environments?

Yes, it supports 0–95% relative humidity, non-condensing.

What is the measurement range of the probe?

±0.25 mm typical displacement.

Is the probe compatible with other 3300 XL system modules?

Yes, it fully integrates with all 3300 XL monitoring modules.

What materials are used for the probe body and tip?

Stainless steel body for durability and ceramic tip for wear resistance and stable measurements.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...