Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

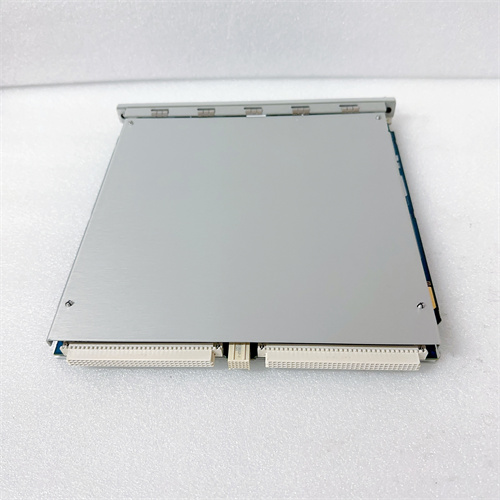

Bently Nevada 330103-02-07-10-02-00 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-02-07-10-02-00

Condition:3300 XL 8 mm Proximity Probe

Origin:USA

Cable length:1m

Weight:0.323 kg

Views:30

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-02-07-10-02-00 is part of the renowned 3300 series from Bently Nevada, a leader in machinery condition monitoring. This product is designed to monitor critical machinery such as turbines, compressors, motors, and pumps. It provides reliable data acquisition and vibration analysis that aids in preventing downtime and ensures machinery operates at peak efficiency.

The 330103-02-07-10-02-00 is specifically engineered to help monitor the health of rotating equipment and collect vibration data in real-time. The data is used to assess the machine’s condition and predict potential failures before they lead to costly repairs or replacements.

Product Specifications

| Specification | Details |

|---|---|

| Model | 330103-02-07-10-02-00 |

| Cable length | 1 m |

| Weight | 0.323 kg |

| Voltage | 24 VDC |

| Power Consumption | 10 Watts |

| Output Type | Analog / Digital Output |

| Operating Temperature Range | -20°C to 60°C |

| Measurement Range | 0 to 1000 Hz (Vibration) |

| Accuracy | ±0.5% |

Applications

Vibration Monitoring: Primarily used for continuous monitoring of vibration levels in rotating machinery. It helps in detecting any unusual behavior or impending failures in equipment such as motors, turbines, and compressors.

Condition Monitoring: The unit can be used to gather condition monitoring data, ensuring that machinery operates within safe parameters.

Preventative Maintenance: The device plays a key role in predicting mechanical failures, enabling maintenance teams to address issues before they result in downtime or catastrophic failures.

Data Collection for Analysis: Data collected by the device is sent to the system’s software for further analysis, making it an integral part of predictive maintenance strategies.

Advantages

High Accuracy: Provides highly accurate and reliable vibration data, which is critical for assessing the condition of rotating machinery.

Cost-Effective: The ability to detect problems early prevents costly repairs, unplanned shutdowns, and equipment replacement.

Real-Time Monitoring: Enables real-time monitoring of machines, giving operators instant access to equipment health data.

Scalable: The product is scalable, which means it can be used across various machines and can grow with your monitoring needs.

Ease of Integration: Designed for easy integration with other Bently Nevada monitoring systems, creating a seamless condition monitoring setup.

Rugged Design: Built to withstand harsh industrial environments, ensuring long-term durability and reliability.

FAQs

1. What machines can the Bently Nevada 330103-02-07-10-02-00 monitor?

-

The 330103-02-07-10-02-00 is designed to monitor a wide range of rotating machinery, including turbines, pumps, motors, compressors, and more.

2. What type of output does this device provide?

-

It provides both analog and digital outputs, enabling integration with various monitoring systems and devices.

3. How does the Bently Nevada 330103-02-07-10-02-00 contribute to predictive maintenance?

-

By continuously monitoring vibration levels and other parameters, it detects anomalies early, preventing unexpected failures and reducing downtime.

4. Is it easy to install the Bently Nevada 330103-02-07-10-02-00?

-

Yes, it is designed for quick and easy installation, with clear documentation to guide users through the process.

5. What is the operating temperature range of the device?

-

The device can operate in temperatures ranging from -20°C to 60°C, making it suitable for a variety of industrial environments.

6. Can this unit be used for real-time data analysis?

-

Yes, the device continuously monitors machinery and sends real-time data to be analyzed either onsite or remotely.

7. How often does the device send vibration data?

-

The frequency of data transmission depends on the configuration and monitoring system, but it typically sends data at regular intervals for ongoing analysis.

8. What type of power supply is required?

-

It requires a 24 VDC power supply to operate efficiently.

9. Can this product work in hazardous environments?

-

Yes, it is designed to work in industrial environments, including hazardous areas, provided the appropriate safety standards are followed.

10. Does it come with software for data analysis?

-

The 330103-02-07-10-02-00 integrates seamlessly with Bently Nevada’s software systems for advanced data analysis and condition monitoring.

Bently Nevada 330103-02-07-10-02-00 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-02-07-10-02-00

Condition:3300 XL 8 mm Proximity Probe

Origin:USA

Cable length:1m

Weight:0.323 kg

Views:30

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-02-07-10-02-00 is part of the renowned 3300 series from Bently Nevada, a leader in machinery condition monitoring. This product is designed to monitor critical machinery such as turbines, compressors, motors, and pumps. It provides reliable data acquisition and vibration analysis that aids in preventing downtime and ensures machinery operates at peak efficiency.

The 330103-02-07-10-02-00 is specifically engineered to help monitor the health of rotating equipment and collect vibration data in real-time. The data is used to assess the machine’s condition and predict potential failures before they lead to costly repairs or replacements.

Product Specifications

| Specification | Details |

|---|---|

| Model | 330103-02-07-10-02-00 |

| Cable length | 1 m |

| Weight | 0.323 kg |

| Voltage | 24 VDC |

| Power Consumption | 10 Watts |

| Output Type | Analog / Digital Output |

| Operating Temperature Range | -20°C to 60°C |

| Measurement Range | 0 to 1000 Hz (Vibration) |

| Accuracy | ±0.5% |

Applications

Vibration Monitoring: Primarily used for continuous monitoring of vibration levels in rotating machinery. It helps in detecting any unusual behavior or impending failures in equipment such as motors, turbines, and compressors.

Condition Monitoring: The unit can be used to gather condition monitoring data, ensuring that machinery operates within safe parameters.

Preventative Maintenance: The device plays a key role in predicting mechanical failures, enabling maintenance teams to address issues before they result in downtime or catastrophic failures.

Data Collection for Analysis: Data collected by the device is sent to the system’s software for further analysis, making it an integral part of predictive maintenance strategies.

Advantages

High Accuracy: Provides highly accurate and reliable vibration data, which is critical for assessing the condition of rotating machinery.

Cost-Effective: The ability to detect problems early prevents costly repairs, unplanned shutdowns, and equipment replacement.

Real-Time Monitoring: Enables real-time monitoring of machines, giving operators instant access to equipment health data.

Scalable: The product is scalable, which means it can be used across various machines and can grow with your monitoring needs.

Ease of Integration: Designed for easy integration with other Bently Nevada monitoring systems, creating a seamless condition monitoring setup.

Rugged Design: Built to withstand harsh industrial environments, ensuring long-term durability and reliability.

FAQs

1. What machines can the Bently Nevada 330103-02-07-10-02-00 monitor?

-

The 330103-02-07-10-02-00 is designed to monitor a wide range of rotating machinery, including turbines, pumps, motors, compressors, and more.

2. What type of output does this device provide?

-

It provides both analog and digital outputs, enabling integration with various monitoring systems and devices.

3. How does the Bently Nevada 330103-02-07-10-02-00 contribute to predictive maintenance?

-

By continuously monitoring vibration levels and other parameters, it detects anomalies early, preventing unexpected failures and reducing downtime.

4. Is it easy to install the Bently Nevada 330103-02-07-10-02-00?

-

Yes, it is designed for quick and easy installation, with clear documentation to guide users through the process.

5. What is the operating temperature range of the device?

-

The device can operate in temperatures ranging from -20°C to 60°C, making it suitable for a variety of industrial environments.

6. Can this unit be used for real-time data analysis?

-

Yes, the device continuously monitors machinery and sends real-time data to be analyzed either onsite or remotely.

7. How often does the device send vibration data?

-

The frequency of data transmission depends on the configuration and monitoring system, but it typically sends data at regular intervals for ongoing analysis.

8. What type of power supply is required?

-

It requires a 24 VDC power supply to operate efficiently.

9. Can this product work in hazardous environments?

-

Yes, it is designed to work in industrial environments, including hazardous areas, provided the appropriate safety standards are followed.

10. Does it come with software for data analysis?

-

The 330103-02-07-10-02-00 integrates seamlessly with Bently Nevada’s software systems for advanced data analysis and condition monitoring.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...