Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

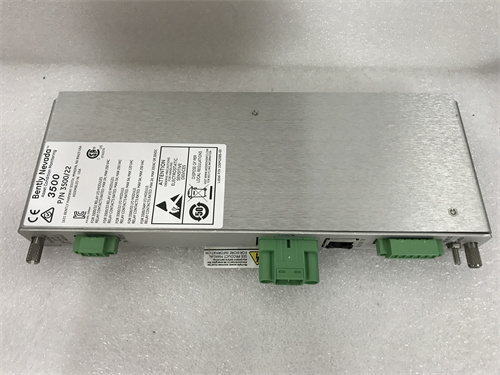

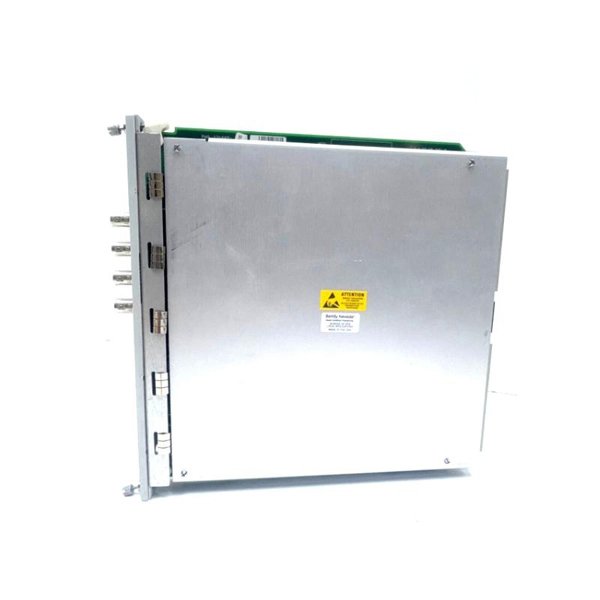

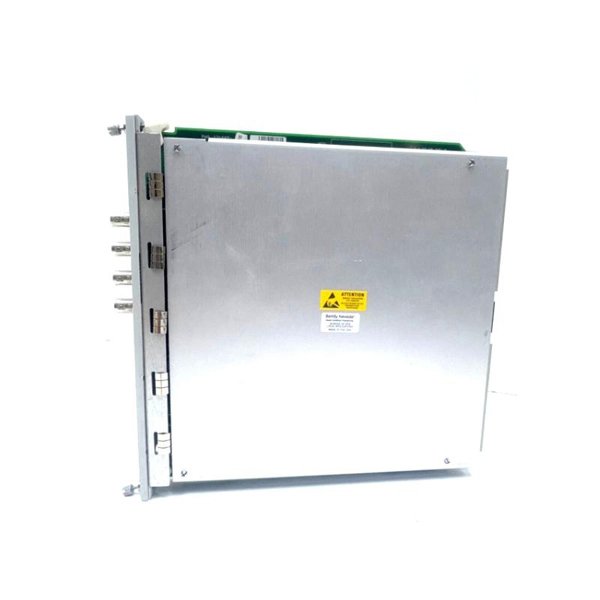

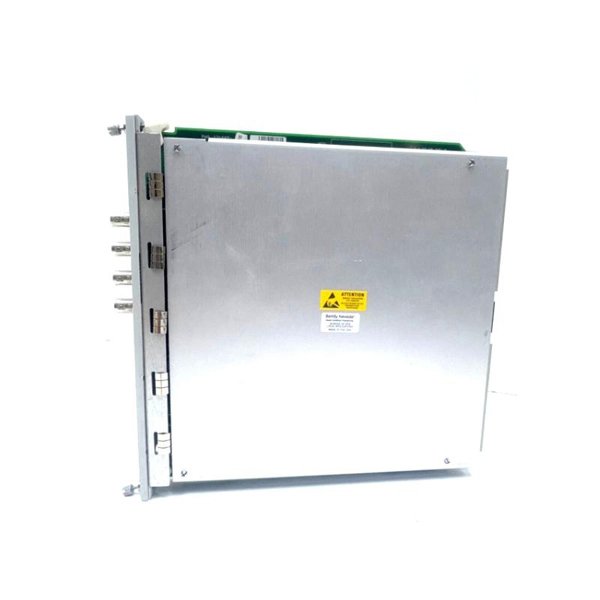

Bently Nevada 3500/42-06-RU Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42-06-RU

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:36

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42-06-RU Proximitor Seismic Monitor is a high-performance module designed for continuous machinery vibration and position monitoring in critical rotating equipment. This monitor interfaces with proximity transducers to detect and measure shaft vibration, position, and phase reference, providing essential data for predictive maintenance and machinery protection.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | 3500/42-06-RU |

| Function | Proximitor Seismic Monitoring |

| Input Channels | 2 independent channels |

| Input Types | Proximity probes, seismic transducers |

| Signal Processing | True RMS, Peak, and Filtered values |

| Power Supply | Via 3500 rack backplane |

| Communication | Compatible with 3500 rack system & software |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Operating Temperature | -30°C to +65°C |

| Humidity | 95% non-condensing |

| Certifications | CE, CSA, ATEX, IECEx |

Applications

-

Continuous monitoring of compressors, turbines, pumps, and generators

Critical machinery protection in power generation, oil & gas, and petrochemical industries

Predictive maintenance programs to reduce unplanned downtime

Integration with plant DCS/SCADA systems for centralized monitoring

Advantages

High Accuracy: Precise vibration and displacement measurement for early fault detection

Flexible Configuration: Supports various proximity probe types and measurement modes

Modular Integration: Works seamlessly with the Bently Nevada 3500 rack system

Robust Design: Industrial-grade reliability in harsh environments

Regulatory Compliance: Certified for hazardous locations and meets global safety standards

FAQ

Q: What types of transducers can be connected to the 3500/42-06-RU?

A: It supports Bently Nevada proximity probes and seismic transducers.

Q: Can it monitor both radial vibration and axial position?

A: Yes, it is designed for multiple measurement modes, including radial vibration, axial position, and phase reference.

Q: How many channels does this monitor have?

A: It features two independent channels.

Q: Is it compatible with all 3500 rack systems?

A: Yes, it integrates with standard 3500 racks and System 1 software.

Q: Can it operate in hazardous areas?

A: Yes, it holds ATEX, CSA, and IECEx certifications.

Q: What is the main advantage over older 3300 series monitors?

A: Enhanced processing capability, better integration, and improved diagnostics.

Q: Does it require calibration?

A: Calibration is recommended during installation and periodically for accuracy assurance.

Q: What is the lifespan of the unit?

A: With proper operation and maintenance, it can exceed 10 years of service life.

Q: Can I configure alarms directly from the module?

A: Alarm settings are configured through the 3500 rack software interface.

Q: Is firmware upgradable?

A: Yes, firmware updates can be applied through the rack system.

Bently Nevada 3500/42-06-RU Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42-06-RU

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:36

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42-06-RU Proximitor Seismic Monitor is a high-performance module designed for continuous machinery vibration and position monitoring in critical rotating equipment. This monitor interfaces with proximity transducers to detect and measure shaft vibration, position, and phase reference, providing essential data for predictive maintenance and machinery protection.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | 3500/42-06-RU |

| Function | Proximitor Seismic Monitoring |

| Input Channels | 2 independent channels |

| Input Types | Proximity probes, seismic transducers |

| Signal Processing | True RMS, Peak, and Filtered values |

| Power Supply | Via 3500 rack backplane |

| Communication | Compatible with 3500 rack system & software |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Operating Temperature | -30°C to +65°C |

| Humidity | 95% non-condensing |

| Certifications | CE, CSA, ATEX, IECEx |

Applications

-

Continuous monitoring of compressors, turbines, pumps, and generators

Critical machinery protection in power generation, oil & gas, and petrochemical industries

Predictive maintenance programs to reduce unplanned downtime

Integration with plant DCS/SCADA systems for centralized monitoring

Advantages

High Accuracy: Precise vibration and displacement measurement for early fault detection

Flexible Configuration: Supports various proximity probe types and measurement modes

Modular Integration: Works seamlessly with the Bently Nevada 3500 rack system

Robust Design: Industrial-grade reliability in harsh environments

Regulatory Compliance: Certified for hazardous locations and meets global safety standards

FAQ

Q: What types of transducers can be connected to the 3500/42-06-RU?

A: It supports Bently Nevada proximity probes and seismic transducers.

Q: Can it monitor both radial vibration and axial position?

A: Yes, it is designed for multiple measurement modes, including radial vibration, axial position, and phase reference.

Q: How many channels does this monitor have?

A: It features two independent channels.

Q: Is it compatible with all 3500 rack systems?

A: Yes, it integrates with standard 3500 racks and System 1 software.

Q: Can it operate in hazardous areas?

A: Yes, it holds ATEX, CSA, and IECEx certifications.

Q: What is the main advantage over older 3300 series monitors?

A: Enhanced processing capability, better integration, and improved diagnostics.

Q: Does it require calibration?

A: Calibration is recommended during installation and periodically for accuracy assurance.

Q: What is the lifespan of the unit?

A: With proper operation and maintenance, it can exceed 10 years of service life.

Q: Can I configure alarms directly from the module?

A: Alarm settings are configured through the 3500 rack software interface.

Q: Is firmware upgradable?

A: Yes, firmware updates can be applied through the rack system.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...