Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

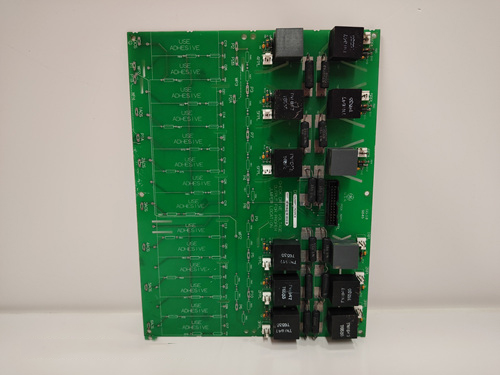

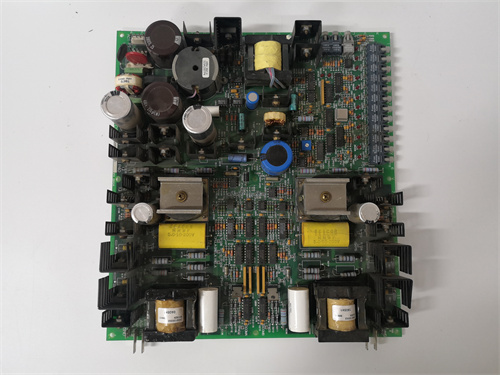

General Electric IS215ACLEH1B Application Control Layer Module

Manufacturer:GE

Product Number:IS215ACLEH1B

Product Type:Application Control Layer Module

Origin:USA

Dimensions:280 × 120 × 22 mm

Weight:0.65 kg

Views:12

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS215ACLEH1B Application Control Layer Module is a high-performance processor card designed for the Mark VIe control system. As part of GE’s advanced turbine and power plant automation platform, the module executes application logic, manages system resources, and ensures deterministic control in demanding industrial environments.

This module belongs to the second generation of ACLE boards, offering improved processing power, enhanced memory resources, and more stable communication interfaces compared to earlier versions. It functions as the core application processor, enabling turbine sequencing, plant coordination, and real-time control of mission-critical equipment.

By combining robust computational capability with industrial-grade reliability, the IS215ACLEH1B supports both simplex and redundant architectures, ensuring system continuity under harsh operating conditions.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | GE IS215ACLEH1B |

| Series | Mark VIe Control System |

| Function | Application Control Layer Module (ACLE) |

| Processor | High-performance industrial CPU with extended instruction set |

| Memory | Onboard SDRAM and Flash memory for control logic and application storage |

| Communication | Dual Ethernet ports (10/100 Mbps) for high-speed deterministic networking |

| Backplane Interface | High-speed VME or proprietary system bus connection |

| Diagnostics | Onboard watchdog, self-test, and error logging |

| Power Supply | Supplied from system backplane (+5 VDC, +12 VDC) |

| Cooling | Passive convection via system rack airflow |

| Operating Temperature | -20 °C to +65 °C |

| Storage Temperature | -40 °C to +85 °C |

| Humidity | 10–90% RH, non-condensing |

| Isolation | Electrical isolation between backplane and external ports |

| Mounting | Rack-mounted plug-in module |

| Dimensions | 280 × 120 × 22 mm |

| Weight | 0.65 kg |

Product Applications

The IS215ACLEH1B is applied in multiple industrial and energy sectors where reliable control is essential:

Gas Turbines – Executes combustion sequencing, fuel scheduling, and protection logic.

Steam Turbines – Controls admission valves, steam extraction, and turbine protection systems.

Generator Control – Handles synchronization, excitation control, and load balancing.

Balance-of-Plant (BoP) Systems – Integrates pumps, fans, compressors, and auxiliary systems into turbine operations.

Redundant Control Architectures – Operates in simplex, dual, or triple modular redundant (TMR) configurations.

Distributed Control Networks – Acts as a core computing node within Mark VIe’s Ethernet-based control system.

Product Advantages

Enhanced Processing Power – Compared to the H1A version, the H1B features higher performance for demanding turbine applications.

Deterministic Execution – Designed to execute real-time control logic with minimal latency.

Strong Network Integration – Dual Ethernet interfaces provide reliable, high-speed communication.

Built-In Diagnostics – Watchdog timers and fault detection improve predictive maintenance.

System Flexibility – Supports multiple control strategies, from simplex to TMR.

High Reliability – Industrial-grade components ensure consistent operation under extreme environments.

Easy Maintenance – Modular design allows quick replacement without disturbing the overall rack system.

Future-Proof Design – Fully compatible with GE Mark VIe platforms and scalable for evolving applications.

FAQ

What is the primary function of the IS215ACLEH1B?

It serves as the application processor in the Mark VIe system, executing turbine and plant control logic.

How does the H1B revision differ from H1A?

The H1B version provides enhanced processing performance and more stable communication interfaces.

Does the module support redundant configurations?

Yes, it is compatible with simplex, dual, and TMR configurations.

What type of communication does it use for control networking?

It uses Ethernet-based deterministic communication for high-speed control.

How does the ACLE module interact with I/O boards?

It exchanges signals through the backplane bus and coordinates with local and remote I/O modules.

Does the module provide onboard diagnostics?

Yes, it has watchdog timers, self-test routines, and error logging to monitor health.

Is the IS215ACLEH1B hot-swappable?

No, it requires system shutdown for replacement, but the modular design ensures rapid serviceability.

How is the control logic stored and executed?

Logic applications are stored in onboard flash memory and executed using RAM resources.

What cooling method does it require?

It relies on passive convection cooling provided by rack airflow; no dedicated fans are needed.

Can it be integrated into non-turbine applications?

Yes, it can be applied in other industrial automation systems requiring deterministic real-time control.

General Electric IS215ACLEH1B Application Control Layer Module

Manufacturer:GE

Product Number:IS215ACLEH1B

Product Type:Application Control Layer Module

Origin:USA

Dimensions:280 × 120 × 22 mm

Weight:0.65 kg

Views:12

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS215ACLEH1B Application Control Layer Module is a high-performance processor card designed for the Mark VIe control system. As part of GE’s advanced turbine and power plant automation platform, the module executes application logic, manages system resources, and ensures deterministic control in demanding industrial environments.

This module belongs to the second generation of ACLE boards, offering improved processing power, enhanced memory resources, and more stable communication interfaces compared to earlier versions. It functions as the core application processor, enabling turbine sequencing, plant coordination, and real-time control of mission-critical equipment.

By combining robust computational capability with industrial-grade reliability, the IS215ACLEH1B supports both simplex and redundant architectures, ensuring system continuity under harsh operating conditions.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | GE IS215ACLEH1B |

| Series | Mark VIe Control System |

| Function | Application Control Layer Module (ACLE) |

| Processor | High-performance industrial CPU with extended instruction set |

| Memory | Onboard SDRAM and Flash memory for control logic and application storage |

| Communication | Dual Ethernet ports (10/100 Mbps) for high-speed deterministic networking |

| Backplane Interface | High-speed VME or proprietary system bus connection |

| Diagnostics | Onboard watchdog, self-test, and error logging |

| Power Supply | Supplied from system backplane (+5 VDC, +12 VDC) |

| Cooling | Passive convection via system rack airflow |

| Operating Temperature | -20 °C to +65 °C |

| Storage Temperature | -40 °C to +85 °C |

| Humidity | 10–90% RH, non-condensing |

| Isolation | Electrical isolation between backplane and external ports |

| Mounting | Rack-mounted plug-in module |

| Dimensions | 280 × 120 × 22 mm |

| Weight | 0.65 kg |

Product Applications

The IS215ACLEH1B is applied in multiple industrial and energy sectors where reliable control is essential:

Gas Turbines – Executes combustion sequencing, fuel scheduling, and protection logic.

Steam Turbines – Controls admission valves, steam extraction, and turbine protection systems.

Generator Control – Handles synchronization, excitation control, and load balancing.

Balance-of-Plant (BoP) Systems – Integrates pumps, fans, compressors, and auxiliary systems into turbine operations.

Redundant Control Architectures – Operates in simplex, dual, or triple modular redundant (TMR) configurations.

Distributed Control Networks – Acts as a core computing node within Mark VIe’s Ethernet-based control system.

Product Advantages

Enhanced Processing Power – Compared to the H1A version, the H1B features higher performance for demanding turbine applications.

Deterministic Execution – Designed to execute real-time control logic with minimal latency.

Strong Network Integration – Dual Ethernet interfaces provide reliable, high-speed communication.

Built-In Diagnostics – Watchdog timers and fault detection improve predictive maintenance.

System Flexibility – Supports multiple control strategies, from simplex to TMR.

High Reliability – Industrial-grade components ensure consistent operation under extreme environments.

Easy Maintenance – Modular design allows quick replacement without disturbing the overall rack system.

Future-Proof Design – Fully compatible with GE Mark VIe platforms and scalable for evolving applications.

FAQ

What is the primary function of the IS215ACLEH1B?

It serves as the application processor in the Mark VIe system, executing turbine and plant control logic.

How does the H1B revision differ from H1A?

The H1B version provides enhanced processing performance and more stable communication interfaces.

Does the module support redundant configurations?

Yes, it is compatible with simplex, dual, and TMR configurations.

What type of communication does it use for control networking?

It uses Ethernet-based deterministic communication for high-speed control.

How does the ACLE module interact with I/O boards?

It exchanges signals through the backplane bus and coordinates with local and remote I/O modules.

Does the module provide onboard diagnostics?

Yes, it has watchdog timers, self-test routines, and error logging to monitor health.

Is the IS215ACLEH1B hot-swappable?

No, it requires system shutdown for replacement, but the modular design ensures rapid serviceability.

How is the control logic stored and executed?

Logic applications are stored in onboard flash memory and executed using RAM resources.

What cooling method does it require?

It relies on passive convection cooling provided by rack airflow; no dedicated fans are needed.

Can it be integrated into non-turbine applications?

Yes, it can be applied in other industrial automation systems requiring deterministic real-time control.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...