Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

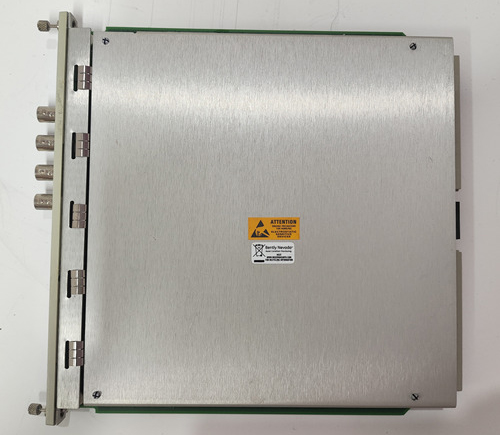

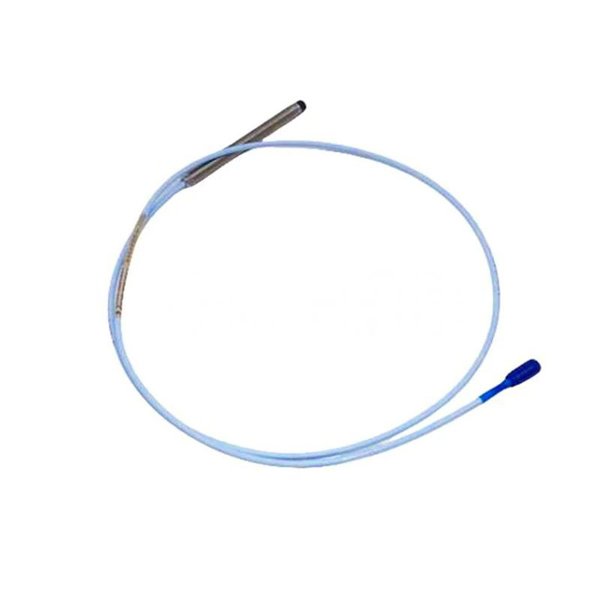

Bently Nevada 330709-000-050-10-02-05 3300 XL 11 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330709-000-050-10-02-05

Product Type:3300 XL 11 mm Proximity Probe

Origin:USA

Total Length:1m

Weight :0.07kg

Views:54

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330709-000-050-10-02-05 is a 3300 XL 11 mm Proximity Probe designed for high-precision measurement of shaft vibration in industrial rotating machinery. This probe is engineered to deliver reliable and accurate proximity measurements under extreme operating conditions, ensuring optimal monitoring and protection of critical machinery. It is widely used in turbomachinery, compressors, and generators, offering superior performance in both steady-state and transient operating conditions.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330709-000-050-10-02-05 |

| Series | 3300 XL |

| Probe Type | 11 mm Proximity Probe |

| Sensor Technology | Eddy-Current |

| Output Signal | Differential Voltage |

| Target Material | Conductive Metals |

| Operating Temperature | -40°C to +120°C |

| Total Length | 1 m |

| Weight | 0.07 kg |

| Housing Material | Stainless Steel |

| Connector Type | Microdot |

| Vibration Sensitivity | High |

| Frequency Response | 0–25 kHz |

| Calibration | Factory Calibrated |

| Insulation Resistance | ≥ 100 MΩ |

| Cable Type | Shielded, PTFE |

Applications

-

Monitoring high-speed turbines and generators in power plants

-

Vibration monitoring of centrifugal and axial compressors

-

Bearing vibration detection in large motors and pumps

-

Rotating machinery condition monitoring in oil and gas, petrochemical, and chemical plants

-

Protective systems for critical rotating equipment

-

Integration with Bently Nevada 3300 XL monitoring systems for continuous diagnostics

Advantages

High Accuracy: Provides precise shaft vibration measurements for critical machinery monitoring.

Robust Design: Stainless steel construction ensures durability in harsh environments.

Wide Temperature Range: Operates reliably from -40°C to +120°C.

Fast Response: Eddy-current technology ensures rapid detection of vibration changes.

Compatibility: Fully compatible with Bently Nevada 3300 XL series monitoring systems.

Compact Size: Lightweight and small form factor allows easy installation in tight spaces.

High Shock Resistance: Resistant to mechanical shocks, minimizing downtime and maintenance costs.

FAQ

Q1: What type of signal output does this probe provide?

A1: The 330709-000-050-10-02-05 provides a differential voltage output compatible with 3300 XL monitoring systems.

Q2: What is the maximum frequency response of the probe?

A2: The probe has a frequency response of 0–25 kHz, suitable for high-speed machinery.

Q3: Is this probe suitable for use in explosive environments?

A3: Yes, when installed with the appropriate intrinsically safe barriers or enclosures, it can be used in hazardous locations.

Q4: What is the operating temperature range?

A4: The probe operates reliably between -40°C and +120°C.

Q5: Can the probe detect shaft displacement in both directions?

A5: Yes, the eddy-current technology allows accurate bidirectional shaft displacement detection.

Q6: What type of connector does the probe use?

A6: It uses a Microdot connector for secure and reliable electrical connection.

Q7: How does this probe perform under high vibration conditions?

A7: The probe has high vibration sensitivity and is shock-resistant up to 50 g for 11 ms, maintaining measurement integrity.

Q8: Can the probe be used with other Bently Nevada systems?

A8: It is optimized for 3300 XL systems but may be compatible with other Bently Nevada monitoring equipment with proper configuration.

Q9: What materials can the probe detect?

A9: The probe is designed to detect conductive metals, commonly used in shaft and rotor applications.

Q10: Does the probe require calibration after installation?

A10: No, the probe is factory calibrated and ready for immediate use with Bently Nevada systems.

Bently Nevada 330709-000-050-10-02-05 3300 XL 11 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330709-000-050-10-02-05

Product Type:3300 XL 11 mm Proximity Probe

Origin:USA

Total Length:1m

Weight :0.07kg

Views:54

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330709-000-050-10-02-05 is a 3300 XL 11 mm Proximity Probe designed for high-precision measurement of shaft vibration in industrial rotating machinery. This probe is engineered to deliver reliable and accurate proximity measurements under extreme operating conditions, ensuring optimal monitoring and protection of critical machinery. It is widely used in turbomachinery, compressors, and generators, offering superior performance in both steady-state and transient operating conditions.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330709-000-050-10-02-05 |

| Series | 3300 XL |

| Probe Type | 11 mm Proximity Probe |

| Sensor Technology | Eddy-Current |

| Output Signal | Differential Voltage |

| Target Material | Conductive Metals |

| Operating Temperature | -40°C to +120°C |

| Total Length | 1 m |

| Weight | 0.07 kg |

| Housing Material | Stainless Steel |

| Connector Type | Microdot |

| Vibration Sensitivity | High |

| Frequency Response | 0–25 kHz |

| Calibration | Factory Calibrated |

| Insulation Resistance | ≥ 100 MΩ |

| Cable Type | Shielded, PTFE |

Applications

-

Monitoring high-speed turbines and generators in power plants

-

Vibration monitoring of centrifugal and axial compressors

-

Bearing vibration detection in large motors and pumps

-

Rotating machinery condition monitoring in oil and gas, petrochemical, and chemical plants

-

Protective systems for critical rotating equipment

-

Integration with Bently Nevada 3300 XL monitoring systems for continuous diagnostics

Advantages

High Accuracy: Provides precise shaft vibration measurements for critical machinery monitoring.

Robust Design: Stainless steel construction ensures durability in harsh environments.

Wide Temperature Range: Operates reliably from -40°C to +120°C.

Fast Response: Eddy-current technology ensures rapid detection of vibration changes.

Compatibility: Fully compatible with Bently Nevada 3300 XL series monitoring systems.

Compact Size: Lightweight and small form factor allows easy installation in tight spaces.

High Shock Resistance: Resistant to mechanical shocks, minimizing downtime and maintenance costs.

FAQ

Q1: What type of signal output does this probe provide?

A1: The 330709-000-050-10-02-05 provides a differential voltage output compatible with 3300 XL monitoring systems.

Q2: What is the maximum frequency response of the probe?

A2: The probe has a frequency response of 0–25 kHz, suitable for high-speed machinery.

Q3: Is this probe suitable for use in explosive environments?

A3: Yes, when installed with the appropriate intrinsically safe barriers or enclosures, it can be used in hazardous locations.

Q4: What is the operating temperature range?

A4: The probe operates reliably between -40°C and +120°C.

Q5: Can the probe detect shaft displacement in both directions?

A5: Yes, the eddy-current technology allows accurate bidirectional shaft displacement detection.

Q6: What type of connector does the probe use?

A6: It uses a Microdot connector for secure and reliable electrical connection.

Q7: How does this probe perform under high vibration conditions?

A7: The probe has high vibration sensitivity and is shock-resistant up to 50 g for 11 ms, maintaining measurement integrity.

Q8: Can the probe be used with other Bently Nevada systems?

A8: It is optimized for 3300 XL systems but may be compatible with other Bently Nevada monitoring equipment with proper configuration.

Q9: What materials can the probe detect?

A9: The probe is designed to detect conductive metals, commonly used in shaft and rotor applications.

Q10: Does the probe require calibration after installation?

A10: No, the probe is factory calibrated and ready for immediate use with Bently Nevada systems.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...