Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

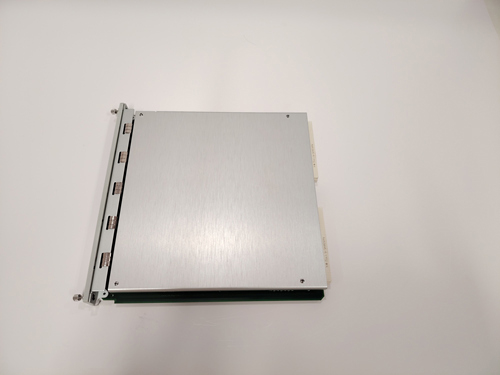

Bently Nevada 330104-00-11-10-02-05 3300 XL 8 mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330104-00-11-10-02-05

Product Type:3300 XL 8 mm Proximity Probes

Origin:USA

Total Length:1 meter

Weight:0.323 kg

Views:45

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330104-00-11-10-02-05 is a premium proximity probe from the 3300 XL 8 mm series, engineered for accurate, non-contact measurement of shaft position and vibration in rotating machinery. As part of GE’s Bently Nevada machinery protection portfolio, this model delivers precise displacement readings for real-time monitoring of critical equipment like turbines, compressors, motors, and pumps.

With an 8 mm sensing tip, M10 x 1 threaded body, and an integral 1.1-meter cable, this model provides high reliability and ease of installation in both OEM and retrofit environments. The “3300 XL” system—consisting of the probe, extension cable, and Proximitor® sensor—is factory-matched for exceptional accuracy and long-term signal integrity.

Designed to perform in high-temperature, high-vibration, and electrically noisy environments, this probe helps prevent costly failures by enabling predictive and preventive maintenance strategies.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | 3300 XL 8 mm Proximity Probe |

| Part Number | 330104-00-11-10-02-05 |

| Series | Bently Nevada 3300 XL |

| Sensing Tip Diameter | 8 mm |

| Thread Type | M10 x 1 |

| Body Length | 55 mm (not including cable) |

| Total Length | 1 meter |

| Connector Type | Right-angle coaxial connector |

| Target Material | 4140 Steel (standard calibration material) |

| Linear Range | 2 mm (80 mils) |

| System Accuracy | ±0.076 mm (±3 mils) typical with matched system components |

| Frequency Response | 0–10 kHz (depends on installation and system configuration) |

| Mounting | Threaded mount with lock nut |

| Temperature Range | −35°C to +177°C (−31°F to +350°F) |

| Humidity | 0–95% RH, non-condensing |

| Vibration Tolerance | 10 g peak, 10–2,000 Hz |

| Shock Resistance | 1000 g, 1 ms duration |

| Environmental Protection | IP65 (with proper cable sealing) |

| Weight | 0.323 kg |

Applications

The 330104-00-11-10-02-05 is widely used in vibration and position monitoring systems across multiple industrial environments, including:

Gas and Steam Turbines – Continuous monitoring of rotor vibration and shaft position.

Centrifugal Compressors – Ensures safe operation by detecting proximity anomalies.

Electric Motors – Tracks radial and axial displacement to prevent bearing damage.

Pumps and Fans – Identifies unbalance, cavitation, or shaft deflection.

Generators and Alternators – Enables condition-based maintenance through real-time feedback.

Gearboxes – Monitors internal movement and alignment of rotating gears.

Product Advantages

High-Precision Measurement – Provides stable, repeatable readings for machine health diagnostics.

Factory-Calibrated System – Matched components ensure exceptional accuracy and linearity.

Compact M10 Thread Size – Allows installation in limited-space applications.

Durability Under Harsh Conditions – Operates in high temperatures, shock, and vibration without signal drift.

Low Electromagnetic Interference (EMI) – Excellent shielding for industrial environments.

Easy Integration – Seamless compatibility with Bently Nevada 3300 XL systems and Proximitor® sensors.

Frequently Asked Questions (FAQ)

What is the main function of this probe?

It measures the distance between the probe tip and a metal surface (typically a rotating shaft) without physical contact.

Is this model part of a complete monitoring system?

Yes. It is used with a matching extension cable and Proximitor® sensor as part of the 3300 XL system.

Can it be used in high-temperature areas?

Yes, it supports operating temperatures up to 177°C (350°F).

What’s the difference between this and a 5 mm probe?

The 8 mm probe offers a longer linear range and is suited for standard installations with more space.

How is this probe installed?

It’s mounted using its threaded body and secured with a lock nut; alignment and gap spacing are critical.

Is the cable replaceable?

No, the integral cable is permanently attached. Any damage requires replacing the entire probe.

Can it be used in hazardous areas?

The probe itself is not intrinsically safe, but the system can be made compliant with proper certified components.

What target materials are supported?

Factory calibration is based on 4140 steel. Other materials may affect sensitivity unless recalibrated.

Is the connector shielded?

Yes, the coaxial connector is shielded against electrical noise and must be properly sealed.

How does it interact with the Proximitor® sensor?

It transmits the signal from the sensing tip through the extension cable to the Proximitor® module for signal processing.

Bently Nevada 330104-00-11-10-02-05 3300 XL 8 mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330104-00-11-10-02-05

Product Type:3300 XL 8 mm Proximity Probes

Origin:USA

Total Length:1 meter

Weight:0.323 kg

Views:45

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330104-00-11-10-02-05 is a premium proximity probe from the 3300 XL 8 mm series, engineered for accurate, non-contact measurement of shaft position and vibration in rotating machinery. As part of GE’s Bently Nevada machinery protection portfolio, this model delivers precise displacement readings for real-time monitoring of critical equipment like turbines, compressors, motors, and pumps.

With an 8 mm sensing tip, M10 x 1 threaded body, and an integral 1.1-meter cable, this model provides high reliability and ease of installation in both OEM and retrofit environments. The “3300 XL” system—consisting of the probe, extension cable, and Proximitor® sensor—is factory-matched for exceptional accuracy and long-term signal integrity.

Designed to perform in high-temperature, high-vibration, and electrically noisy environments, this probe helps prevent costly failures by enabling predictive and preventive maintenance strategies.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | 3300 XL 8 mm Proximity Probe |

| Part Number | 330104-00-11-10-02-05 |

| Series | Bently Nevada 3300 XL |

| Sensing Tip Diameter | 8 mm |

| Thread Type | M10 x 1 |

| Body Length | 55 mm (not including cable) |

| Total Length | 1 meter |

| Connector Type | Right-angle coaxial connector |

| Target Material | 4140 Steel (standard calibration material) |

| Linear Range | 2 mm (80 mils) |

| System Accuracy | ±0.076 mm (±3 mils) typical with matched system components |

| Frequency Response | 0–10 kHz (depends on installation and system configuration) |

| Mounting | Threaded mount with lock nut |

| Temperature Range | −35°C to +177°C (−31°F to +350°F) |

| Humidity | 0–95% RH, non-condensing |

| Vibration Tolerance | 10 g peak, 10–2,000 Hz |

| Shock Resistance | 1000 g, 1 ms duration |

| Environmental Protection | IP65 (with proper cable sealing) |

| Weight | 0.323 kg |

Applications

The 330104-00-11-10-02-05 is widely used in vibration and position monitoring systems across multiple industrial environments, including:

Gas and Steam Turbines – Continuous monitoring of rotor vibration and shaft position.

Centrifugal Compressors – Ensures safe operation by detecting proximity anomalies.

Electric Motors – Tracks radial and axial displacement to prevent bearing damage.

Pumps and Fans – Identifies unbalance, cavitation, or shaft deflection.

Generators and Alternators – Enables condition-based maintenance through real-time feedback.

Gearboxes – Monitors internal movement and alignment of rotating gears.

Product Advantages

High-Precision Measurement – Provides stable, repeatable readings for machine health diagnostics.

Factory-Calibrated System – Matched components ensure exceptional accuracy and linearity.

Compact M10 Thread Size – Allows installation in limited-space applications.

Durability Under Harsh Conditions – Operates in high temperatures, shock, and vibration without signal drift.

Low Electromagnetic Interference (EMI) – Excellent shielding for industrial environments.

Easy Integration – Seamless compatibility with Bently Nevada 3300 XL systems and Proximitor® sensors.

Frequently Asked Questions (FAQ)

What is the main function of this probe?

It measures the distance between the probe tip and a metal surface (typically a rotating shaft) without physical contact.

Is this model part of a complete monitoring system?

Yes. It is used with a matching extension cable and Proximitor® sensor as part of the 3300 XL system.

Can it be used in high-temperature areas?

Yes, it supports operating temperatures up to 177°C (350°F).

What’s the difference between this and a 5 mm probe?

The 8 mm probe offers a longer linear range and is suited for standard installations with more space.

How is this probe installed?

It’s mounted using its threaded body and secured with a lock nut; alignment and gap spacing are critical.

Is the cable replaceable?

No, the integral cable is permanently attached. Any damage requires replacing the entire probe.

Can it be used in hazardous areas?

The probe itself is not intrinsically safe, but the system can be made compliant with proper certified components.

What target materials are supported?

Factory calibration is based on 4140 steel. Other materials may affect sensitivity unless recalibrated.

Is the connector shielded?

Yes, the coaxial connector is shielded against electrical noise and must be properly sealed.

How does it interact with the Proximitor® sensor?

It transmits the signal from the sensing tip through the extension cable to the Proximitor® module for signal processing.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...