Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

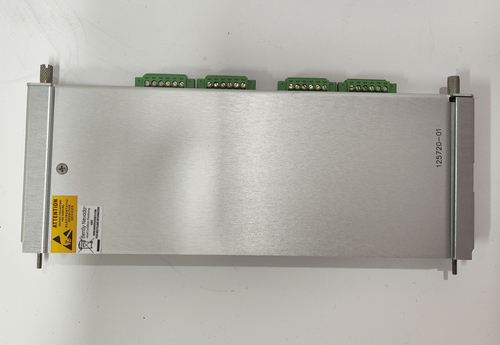

Bently Nevada 330100-90-05 3300 Proximitor Sensor

Manufacturer:Bently Nevada

Product Number:330100-90-05

Product Type:3300 Proximitor Sensor

Origin:USA

Total Length:9 meters

Weight:0.25 kg

Views:70

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330100-90-05 3300 Proximitor Sensor is a key component of the 3300 series machinery protection system, widely recognized in the field of industrial condition monitoring. Designed to accurately measure vibration and displacement in rotating machinery, this sensor provides reliable, high-resolution data essential for detecting early signs of equipment wear, imbalance, or misalignment. The sensor operates on proximity probe technology, allowing non-contact measurement that reduces wear and tear and enables continuous monitoring in harsh industrial environments.

Built with precision engineering, the 330100-90-05 is compatible with various machinery, including turbines, compressors, and motors. Its rugged construction ensures stable performance even in high-temperature or high-vibration settings. The sensor integrates seamlessly into Bently Nevada’s 3300 monitoring systems, providing critical data that facilitates predictive maintenance strategies, reduces downtime, and enhances operational safety.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | 330100-90-05 3300 Proximitor Sensor |

| Measurement Principle | Proximity probe (eddy current) |

| Sensor Type | Displacement/Vibration sensor |

| Operating Frequency Range | DC to 10 kHz |

| Probe Tip Style | Spring-loaded plunger |

| Probe Tip Material | Tungsten carbide |

| Measurement Range | Typically ±0.25 mm (±10 mils) |

| Sensitivity | Approximately 50 mV/mil (1.97 mV/µm) |

| Operating Temperature Range | -40°C to +125°C |

| Power Supply Requirements | 18 to 30 V DC |

| Output Signal | AC signal proportional to displacement |

| Housing Material | Stainless steel |

| Cable Type | Coaxial, shielded |

| Total Length | 9 meters |

| Weight | 0.25 kg |

Applications

-

Continuous vibration and shaft displacement monitoring in rotating machinery

-

Condition monitoring of turbines, compressors, pumps, and motors

-

Early fault detection for bearings, shaft misalignment, and unbalance

-

Use in power generation, petrochemical, and manufacturing industries

-

Integration into machinery protection systems for automated shutdown or alarm functions

-

Environments with high vibration, temperature, and industrial contaminants

Advantages

High Precision Measurement: Provides accurate displacement and vibration data critical for early fault detection.

Non-contact Operation: Eddy current technology ensures wear-free, maintenance-free operation.

Robust Construction: Stainless steel housing and tungsten carbide tip ensure durability in harsh environments.

Wide Operating Temperature: Operates reliably in a broad temperature range suitable for industrial conditions.

Seamless Integration: Compatible with Bently Nevada’s 3300 Series monitoring systems and other industrial control equipment.

Fast Response Time: Enables real-time monitoring and timely alarms to prevent machinery failure.

High Sensitivity: Detects minute changes in shaft position or vibration for detailed condition assessment.

FAQ

What measurement principle does the 330100-90-05 sensor use?

It uses eddy current proximity probe technology for non-contact displacement measurement.

What is the typical measurement range of this sensor?

Typically ±0.25 mm (±10 mils).

What is the output signal type from the sensor?

An AC signal proportional to shaft displacement.

What power supply voltage is required?

The sensor requires 18 to 30 V DC for operation.

What is the operating temperature range?

The sensor operates reliably between -40°C and +125°C.

What type of cable is recommended for the sensor connection?

Coaxial shielded cable is recommended for noise immunity.

What materials are used for the sensor tip and housing?

The probe tip is made of tungsten carbide; housing is stainless steel.

Is the sensor suitable for use in high-vibration environments?

Yes, it is designed for robust operation in harsh, high-vibration industrial environments.

What is the sensor’s sensitivity?

Approximately 50 mV/mil (1.97 mV/µm).

What machinery types are compatible with this sensor?

It is compatible with turbines, compressors, pumps, and electric motors.

Bently Nevada 330100-90-05 3300 Proximitor Sensor

Manufacturer:Bently Nevada

Product Number:330100-90-05

Product Type:3300 Proximitor Sensor

Origin:USA

Total Length:9 meters

Weight:0.25 kg

Views:70

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330100-90-05 3300 Proximitor Sensor is a key component of the 3300 series machinery protection system, widely recognized in the field of industrial condition monitoring. Designed to accurately measure vibration and displacement in rotating machinery, this sensor provides reliable, high-resolution data essential for detecting early signs of equipment wear, imbalance, or misalignment. The sensor operates on proximity probe technology, allowing non-contact measurement that reduces wear and tear and enables continuous monitoring in harsh industrial environments.

Built with precision engineering, the 330100-90-05 is compatible with various machinery, including turbines, compressors, and motors. Its rugged construction ensures stable performance even in high-temperature or high-vibration settings. The sensor integrates seamlessly into Bently Nevada’s 3300 monitoring systems, providing critical data that facilitates predictive maintenance strategies, reduces downtime, and enhances operational safety.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | 330100-90-05 3300 Proximitor Sensor |

| Measurement Principle | Proximity probe (eddy current) |

| Sensor Type | Displacement/Vibration sensor |

| Operating Frequency Range | DC to 10 kHz |

| Probe Tip Style | Spring-loaded plunger |

| Probe Tip Material | Tungsten carbide |

| Measurement Range | Typically ±0.25 mm (±10 mils) |

| Sensitivity | Approximately 50 mV/mil (1.97 mV/µm) |

| Operating Temperature Range | -40°C to +125°C |

| Power Supply Requirements | 18 to 30 V DC |

| Output Signal | AC signal proportional to displacement |

| Housing Material | Stainless steel |

| Cable Type | Coaxial, shielded |

| Total Length | 9 meters |

| Weight | 0.25 kg |

Applications

-

Continuous vibration and shaft displacement monitoring in rotating machinery

-

Condition monitoring of turbines, compressors, pumps, and motors

-

Early fault detection for bearings, shaft misalignment, and unbalance

-

Use in power generation, petrochemical, and manufacturing industries

-

Integration into machinery protection systems for automated shutdown or alarm functions

-

Environments with high vibration, temperature, and industrial contaminants

Advantages

High Precision Measurement: Provides accurate displacement and vibration data critical for early fault detection.

Non-contact Operation: Eddy current technology ensures wear-free, maintenance-free operation.

Robust Construction: Stainless steel housing and tungsten carbide tip ensure durability in harsh environments.

Wide Operating Temperature: Operates reliably in a broad temperature range suitable for industrial conditions.

Seamless Integration: Compatible with Bently Nevada’s 3300 Series monitoring systems and other industrial control equipment.

Fast Response Time: Enables real-time monitoring and timely alarms to prevent machinery failure.

High Sensitivity: Detects minute changes in shaft position or vibration for detailed condition assessment.

FAQ

What measurement principle does the 330100-90-05 sensor use?

It uses eddy current proximity probe technology for non-contact displacement measurement.

What is the typical measurement range of this sensor?

Typically ±0.25 mm (±10 mils).

What is the output signal type from the sensor?

An AC signal proportional to shaft displacement.

What power supply voltage is required?

The sensor requires 18 to 30 V DC for operation.

What is the operating temperature range?

The sensor operates reliably between -40°C and +125°C.

What type of cable is recommended for the sensor connection?

Coaxial shielded cable is recommended for noise immunity.

What materials are used for the sensor tip and housing?

The probe tip is made of tungsten carbide; housing is stainless steel.

Is the sensor suitable for use in high-vibration environments?

Yes, it is designed for robust operation in harsh, high-vibration industrial environments.

What is the sensor’s sensitivity?

Approximately 50 mV/mil (1.97 mV/µm).

What machinery types are compatible with this sensor?

It is compatible with turbines, compressors, pumps, and electric motors.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...