Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

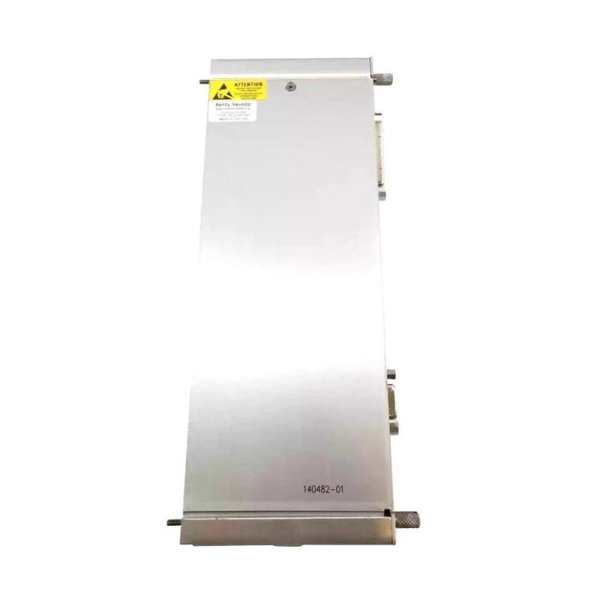

Bently Nevada 3500/72M 140482-01 Prox/Velom I/O Module

Manufacturer:Bently Nevada

Product Number:3500/72M 140482-01

Product Type:Prox/Velom I/O Module

Origin:USA

Dimensions:241.3 x 24.4 x 99.1 mm

Weight:0.20 kg

Views:47

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/72M 140482-01 Prox/Velom I/O Module is part of the 3500 Machinery Protection System, specifically designed for reciprocating compressors. This four-channel monitor processes input from proximity transducers to measure rod position, rod drop, and other dynamic values. It supports advanced diagnostics and alarm capabilities for real-time machinery health monitoring.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Model | 3500/72M 140482-01 |

| Input Channels | 4 Proximity Probe Inputs |

| Input Impedance | 10 kΩ |

| Output Impedance | 510 Ω |

| Transducer Power Supply | -24 VDC |

| Power Consumption | 7.7 W (nominal) |

| Dimensions (H x W x D) | 241.3 x 24.4 x 99.1 mm |

| Weight | 0.20 kg |

| Operating Temperature | -30°C to +65°C (External Termination) |

| Storage Temperature | -40°C to +85°C |

| Humidity | 95% non-condensing |

| Mounting | 1 full-height rear slot in 3500 rack |

| Certifications | ATEX, IECEx, cNRTLus, EMC, RoHS, DNV, ABS |

| Communication | TX/RX LED indicators for module interaction |

| Buffered Output | Coaxial per channel (short-circuit protected) |

Applications

-

Reciprocating compressors in petrochemical and oil & gas industries

-

Hyper-compressor rod position and displacement monitoring

-

Machinery protection for high-value equipment

-

Compliance with API 618 for reciprocating compressors

Key Advantages

-

Real-time monitoring of rod position, drop, and vibration characteristics

-

Fully programmable alarm and trip logic for machinery protection

-

Compatibility with proximity probes and Velomitor sensors

-

Meets API 618 and global safety certifications

-

Buffered outputs for diagnostics and analysis

-

Supports multiple rod monitoring modes in a single module

FAQ

Q1: What types of sensors are supported by the 3500/72M 140482-01 module?

A1: It supports proximity probes and Velomitor sensors for dynamic and static measurements.

Q2: Can this module monitor rod drop and piston position simultaneously?

A2: Yes, the channels can be configured to monitor multiple parameters such as rod drop, position magnitude, and piston position.

Q3: What is the purpose of the buffered outputs on this module?

A3: Buffered outputs allow real-time signal analysis without interrupting monitoring functions.

Q4: How is the alarm configuration managed?

A4: Alarm setpoints and delays are configured using the 3500 Rack Configuration Software.

Q5: What safety certifications does this module carry?

A5: It complies with ATEX, IECEx, cNRTLus, RoHS, EMC, and maritime (DNV, ABS) standards.

Q6: What rack slot does the I/O module occupy?

A6: It occupies one full-height rear slot in the Bently Nevada 3500 rack.

Q7: Is this module suitable for low-speed compressors?

A7: Yes, with a modification, it supports speeds down to 30 RPM.

Q8: How accurate are the rod position measurements?

A8: Measurement accuracy is within ±0.33% of full scale (typical), ±1% max.

Q9: What is the minimum machine speed supported for 1X/2X analysis?

A9: The valid speed range is 60 cpm to 2130 cpm.

Q10: Can this module be used in hazardous areas?

A10: Yes, with proper approval options and barrier configurations, it is certified for hazardous areas.

Bently Nevada 3500/72M 140482-01 Prox/Velom I/O Module

Manufacturer:Bently Nevada

Product Number:3500/72M 140482-01

Product Type:Prox/Velom I/O Module

Origin:USA

Dimensions:241.3 x 24.4 x 99.1 mm

Weight:0.20 kg

Views:47

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/72M 140482-01 Prox/Velom I/O Module is part of the 3500 Machinery Protection System, specifically designed for reciprocating compressors. This four-channel monitor processes input from proximity transducers to measure rod position, rod drop, and other dynamic values. It supports advanced diagnostics and alarm capabilities for real-time machinery health monitoring.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Model | 3500/72M 140482-01 |

| Input Channels | 4 Proximity Probe Inputs |

| Input Impedance | 10 kΩ |

| Output Impedance | 510 Ω |

| Transducer Power Supply | -24 VDC |

| Power Consumption | 7.7 W (nominal) |

| Dimensions (H x W x D) | 241.3 x 24.4 x 99.1 mm |

| Weight | 0.20 kg |

| Operating Temperature | -30°C to +65°C (External Termination) |

| Storage Temperature | -40°C to +85°C |

| Humidity | 95% non-condensing |

| Mounting | 1 full-height rear slot in 3500 rack |

| Certifications | ATEX, IECEx, cNRTLus, EMC, RoHS, DNV, ABS |

| Communication | TX/RX LED indicators for module interaction |

| Buffered Output | Coaxial per channel (short-circuit protected) |

Applications

-

Reciprocating compressors in petrochemical and oil & gas industries

-

Hyper-compressor rod position and displacement monitoring

-

Machinery protection for high-value equipment

-

Compliance with API 618 for reciprocating compressors

Key Advantages

-

Real-time monitoring of rod position, drop, and vibration characteristics

-

Fully programmable alarm and trip logic for machinery protection

-

Compatibility with proximity probes and Velomitor sensors

-

Meets API 618 and global safety certifications

-

Buffered outputs for diagnostics and analysis

-

Supports multiple rod monitoring modes in a single module

FAQ

Q1: What types of sensors are supported by the 3500/72M 140482-01 module?

A1: It supports proximity probes and Velomitor sensors for dynamic and static measurements.

Q2: Can this module monitor rod drop and piston position simultaneously?

A2: Yes, the channels can be configured to monitor multiple parameters such as rod drop, position magnitude, and piston position.

Q3: What is the purpose of the buffered outputs on this module?

A3: Buffered outputs allow real-time signal analysis without interrupting monitoring functions.

Q4: How is the alarm configuration managed?

A4: Alarm setpoints and delays are configured using the 3500 Rack Configuration Software.

Q5: What safety certifications does this module carry?

A5: It complies with ATEX, IECEx, cNRTLus, RoHS, EMC, and maritime (DNV, ABS) standards.

Q6: What rack slot does the I/O module occupy?

A6: It occupies one full-height rear slot in the Bently Nevada 3500 rack.

Q7: Is this module suitable for low-speed compressors?

A7: Yes, with a modification, it supports speeds down to 30 RPM.

Q8: How accurate are the rod position measurements?

A8: Measurement accuracy is within ±0.33% of full scale (typical), ±1% max.

Q9: What is the minimum machine speed supported for 1X/2X analysis?

A9: The valid speed range is 60 cpm to 2130 cpm.

Q10: Can this module be used in hazardous areas?

A10: Yes, with proper approval options and barrier configurations, it is certified for hazardous areas.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...