Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

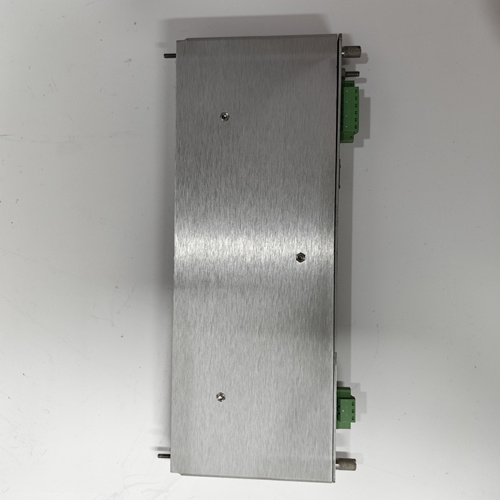

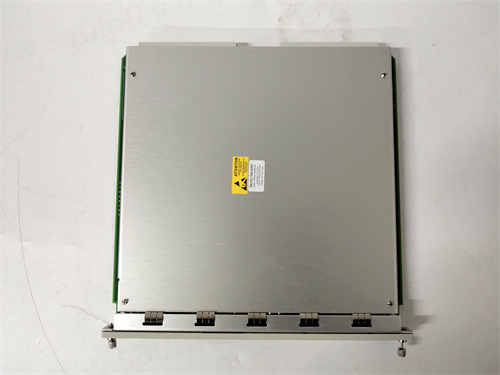

Bently Nevada 330104-00-06-05-01-00 3300 XL 8 mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330104-00-06-05-01-00

Product Type:3300 XL 8 mm Proximity Probes

Origin:USA

Total Length:0.5 meter

Weight:0.162 kg

Views:8

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330104-00-06-05-01-00 is part of the 3300 XL 8 mm Proximity Probe System, designed for highly accurate non-contact measurement of shaft vibration and displacement in critical rotating machinery. Built on Bently Nevada’s long-standing expertise in machinery protection and condition monitoring, this probe ensures stable performance in demanding industrial conditions such as turbines, compressors, pumps, and motors.

Its 8 mm tip design enables precise proximity measurements with excellent linearity across its operating range. This model is engineered for compatibility with the 3300 XL extension cables and Proximitor® sensors, forming a complete system that converts mechanical movement into a reliable electrical signal for diagnostics and protection.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | 330104-00-06-05-01-00 |

| Series | 3300 XL 8 mm Proximity Probe |

| Probe Tip Diameter | 8 mm |

| Total Length | 0.5 meter |

| Weight | 0.162 kg |

| Linear Range | 2 mm typical |

| Frequency Response | Up to 10 kHz |

| Operating Temperature | -35 °C to +177 °C |

| Probe Material | Stainless steel with hermetically sealed tip |

| Connection Type | Coaxial connector with click-lock mechanism |

| Compatible Target Material | Optimized for 4140 steel (with conversion factors for others) |

| System Components | Probe + Extension Cable + Proximitor® Module |

Product Applications

The 3300 XL 8 mm proximity probe is widely adopted in industrial monitoring systems where precision and reliability are critical. Typical applications include:

-

Monitoring shaft vibration in turbines, compressors, and pumps.

-

Measuring shaft axial position and thrust clearance in rotating equipment.

-

Detecting radial displacement for predictive maintenance and fault prevention.

-

Integration into machinery protection systems to prevent catastrophic failures.

-

Supporting condition monitoring programs for early fault detection.

-

Providing reliable data for rotor dynamics analysis in research and development.

Product Advantages

The Bently Nevada 330104-00-06-05-01-00 proximity probe offers several advantages:

High Accuracy – Provides precise non-contact measurement of shaft vibration and position.

Durability – Built with corrosion-resistant materials and hermetically sealed for harsh environments.

Wide Temperature Range – Operates reliably across extreme industrial temperatures.

System Compatibility – Works seamlessly with 3300 XL extension cables and Proximitor® sensors.

Noise Immunity – Designed with shielding and robust connectors to resist EMI and signal interference.

Versatility – Supports both static and dynamic measurements, making it suitable for various machinery types.

Proven Reliability – Backed by decades of Bently Nevada’s expertise in machinery monitoring technology.

FAQ

What is the linear measurement range of the 3300 XL 8 mm proximity probe?

It provides a linear measurement range of approximately 2 mm, optimized for 4140 steel targets.

Which target materials can this probe accurately measure?

While optimized for 4140 steel, it can measure other conductive materials using calibration factors.

How does the probe integrate with the Proximitor® module?

It connects via coaxial cabling and works as part of a three-component system (probe, cable, Proximitor).

What kind of electrical output does the probe generate?

It produces a voltage proportional to the distance between the probe and the target surface.

Can the probe handle high-frequency vibration monitoring?

Yes, it supports dynamic response up to 10 kHz, making it suitable for high-speed machinery.

Is recalibration required after replacing the probe?

Yes, calibration with its dedicated Proximitor® is recommended to maintain accuracy.

How is the probe protected against contamination and harsh conditions?

It has a hermetically sealed stainless-steel body resistant to oil, dust, and moisture.

Does temperature variation affect the probe’s accuracy?

The system is temperature-compensated within its specified operating range to reduce drift.

Can it be used for both vibration and position monitoring?

Yes, it measures both static displacement and dynamic vibration simultaneously.

How does the system ensure immunity against electromagnetic interference?

The probe and cables use shielding and grounded connections to minimize EMI effects.

Bently Nevada 330104-00-06-05-01-00 3300 XL 8 mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330104-00-06-05-01-00

Product Type:3300 XL 8 mm Proximity Probes

Origin:USA

Total Length:0.5 meter

Weight:0.162 kg

Views:8

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330104-00-06-05-01-00 is part of the 3300 XL 8 mm Proximity Probe System, designed for highly accurate non-contact measurement of shaft vibration and displacement in critical rotating machinery. Built on Bently Nevada’s long-standing expertise in machinery protection and condition monitoring, this probe ensures stable performance in demanding industrial conditions such as turbines, compressors, pumps, and motors.

Its 8 mm tip design enables precise proximity measurements with excellent linearity across its operating range. This model is engineered for compatibility with the 3300 XL extension cables and Proximitor® sensors, forming a complete system that converts mechanical movement into a reliable electrical signal for diagnostics and protection.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | 330104-00-06-05-01-00 |

| Series | 3300 XL 8 mm Proximity Probe |

| Probe Tip Diameter | 8 mm |

| Total Length | 0.5 meter |

| Weight | 0.162 kg |

| Linear Range | 2 mm typical |

| Frequency Response | Up to 10 kHz |

| Operating Temperature | -35 °C to +177 °C |

| Probe Material | Stainless steel with hermetically sealed tip |

| Connection Type | Coaxial connector with click-lock mechanism |

| Compatible Target Material | Optimized for 4140 steel (with conversion factors for others) |

| System Components | Probe + Extension Cable + Proximitor® Module |

Product Applications

The 3300 XL 8 mm proximity probe is widely adopted in industrial monitoring systems where precision and reliability are critical. Typical applications include:

-

Monitoring shaft vibration in turbines, compressors, and pumps.

-

Measuring shaft axial position and thrust clearance in rotating equipment.

-

Detecting radial displacement for predictive maintenance and fault prevention.

-

Integration into machinery protection systems to prevent catastrophic failures.

-

Supporting condition monitoring programs for early fault detection.

-

Providing reliable data for rotor dynamics analysis in research and development.

Product Advantages

The Bently Nevada 330104-00-06-05-01-00 proximity probe offers several advantages:

High Accuracy – Provides precise non-contact measurement of shaft vibration and position.

Durability – Built with corrosion-resistant materials and hermetically sealed for harsh environments.

Wide Temperature Range – Operates reliably across extreme industrial temperatures.

System Compatibility – Works seamlessly with 3300 XL extension cables and Proximitor® sensors.

Noise Immunity – Designed with shielding and robust connectors to resist EMI and signal interference.

Versatility – Supports both static and dynamic measurements, making it suitable for various machinery types.

Proven Reliability – Backed by decades of Bently Nevada’s expertise in machinery monitoring technology.

FAQ

What is the linear measurement range of the 3300 XL 8 mm proximity probe?

It provides a linear measurement range of approximately 2 mm, optimized for 4140 steel targets.

Which target materials can this probe accurately measure?

While optimized for 4140 steel, it can measure other conductive materials using calibration factors.

How does the probe integrate with the Proximitor® module?

It connects via coaxial cabling and works as part of a three-component system (probe, cable, Proximitor).

What kind of electrical output does the probe generate?

It produces a voltage proportional to the distance between the probe and the target surface.

Can the probe handle high-frequency vibration monitoring?

Yes, it supports dynamic response up to 10 kHz, making it suitable for high-speed machinery.

Is recalibration required after replacing the probe?

Yes, calibration with its dedicated Proximitor® is recommended to maintain accuracy.

How is the probe protected against contamination and harsh conditions?

It has a hermetically sealed stainless-steel body resistant to oil, dust, and moisture.

Does temperature variation affect the probe’s accuracy?

The system is temperature-compensated within its specified operating range to reduce drift.

Can it be used for both vibration and position monitoring?

Yes, it measures both static displacement and dynamic vibration simultaneously.

How does the system ensure immunity against electromagnetic interference?

The probe and cables use shielding and grounded connections to minimize EMI effects.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...