Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

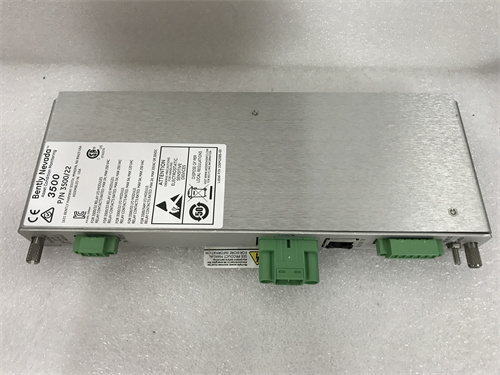

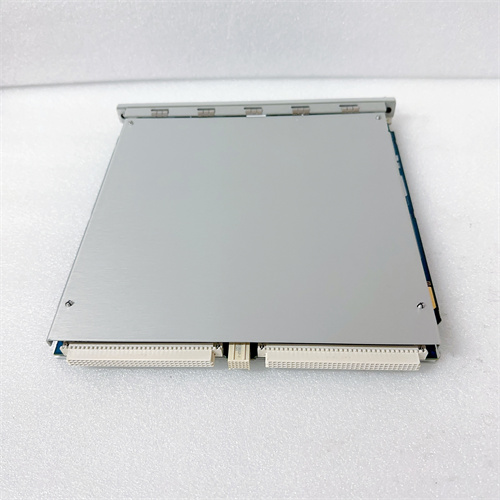

Bently Nevada 330103-03-10-10-11-00 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330103-03-10-10-11-00

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:1 meter

Weight:0.323 kg

Views:11

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-03-10-10-11-00 3300 XL 8mm Proximity Probe is a precision-engineered sensor specifically developed for machinery monitoring and protection systems. Part of the trusted 3300 XL series, it is widely recognized in industries such as power generation, oil & gas, petrochemical, and manufacturing. This probe operates by detecting the distance between the probe tip and a conductive target surface, typically a rotating shaft. The accurate gap measurement enables continuous monitoring of vibration, axial displacement, and rotor dynamics, ensuring early detection of machinery issues before they escalate.

The 330103-03-10-10-11-00 model is designed for high stability, long-term reliability, and compatibility with the full Bently Nevada 3300 monitoring platform. With its rugged design, stable signal transmission, and superior temperature tolerance, it ensures that critical rotating machinery operates within safe and efficient parameters.

Product Parameters

| Parameter | Specification |

|---|---|

| Product Model | Bently Nevada 330103-03-10-10-11-00 |

| Series | 3300 XL 8mm Proximity Probes |

| Probe Tip Diameter | 8 mm |

| Total Length | 1 meter |

| Weight | 0.323 kg |

| Sensitivity | -7.87 V/mm (typical) |

| Linearity Range | ± 0.076 mm (within 200 µm gap) |

| Frequency Response | DC to 10 kHz |

| Operating Gap Range | 0.25 mm to 2.0 mm |

| Compatible Proximitor | 3300 XL Proximitor Sensor |

| Cable Type | Integral coaxial cable |

| Operating Temperature | -35 °C to +180 °C |

| Storage Temperature | -50 °C to +200 °C |

| Pressure Resistance | Suitable for high-pressure sealed environments |

| Connector Type | Standard BNC or click-on connector depending on configuration |

| Certifications | CE, ATEX, CSA, and other industry-relevant standards |

Product Applications

The 330103-03-10-10-11-00 probe plays a central role in machinery health management. Its applications include:

-

Vibration Monitoring: Continuous observation of shaft vibration in turbines, compressors, and motors.

-

Axial Position Measurement: Detects rotor thrust movement to prevent mechanical damage.

-

Rotating Equipment Protection: Essential in critical equipment like gas turbines, steam turbines, pumps, and compressors.

-

Condition Monitoring: Works as a vital sensor input for predictive maintenance systems.

-

Integration with Control Systems: Directly interfaces with Bently Nevada 3300 monitoring platforms and PLC/DCS systems for automated machinery protection.

Product Advantages

-

High Accuracy and Reliability: Delivers precise measurements even in high-temperature and high-pressure environments.

-

Rugged Design: Built to withstand harsh industrial conditions, including vibration and corrosive atmospheres.

-

Wide Compatibility: Fully compatible with the 3300 XL Proximitor sensors and monitoring systems.

-

Long-Term Stability: Provides consistent performance, minimizing calibration needs.

-

Predictive Maintenance Benefits: Helps reduce unexpected shutdowns by detecting problems early.

-

Industry Proven: Trusted by industries worldwide for over three decades, making it a standard in machinery protection.

FAQ

1. How does the 330103-03-10-10-11-00 proximity probe achieve accurate displacement measurement?

It uses an eddy current principle where the probe generates an electromagnetic field that induces currents in the target surface. The variation in the return signal is directly correlated with shaft displacement, ensuring high measurement accuracy.

2. Can this probe be used interchangeably with other Bently Nevada 3300 XL probes?

Yes, as long as the probe is paired with the correct 3300 XL Proximitor sensor, it maintains calibration and ensures interchangeability within the series.

3. What is the maximum frequency range the probe can detect?

The probe supports a frequency response from DC up to 10 kHz, making it suitable for most rotating machinery vibration monitoring applications.

4. How does the probe maintain stability in high-temperature environments?

It is designed with specialized materials and insulation that allow continuous operation from -35 °C to +180 °C, ensuring reliable performance in thermal stress conditions.

5. Is the probe affected by environmental electromagnetic interference (EMI)?

No, the integral coaxial cable and shielded construction provide effective resistance to EMI, maintaining signal integrity.

6. How does the probe ensure long-term calibration accuracy?

Bently Nevada probes are manufactured with tight tolerances, and the system is factory calibrated. When paired correctly with its matching Proximitor, calibration remains stable throughout its service life.

7. Can the probe detect both static and dynamic displacements?

Yes, it can measure static shaft position (e.g., thrust movement) as well as dynamic vibration signals, providing dual functionality in machinery monitoring.

8. What role does the cable length play in probe performance?

Cable length is factory-matched and calibrated to ensure correct sensitivity and linearity. Altering cable length without recalibration can cause measurement errors.

9. How does this probe contribute to predictive maintenance strategies?

By providing real-time vibration and position data, the probe enables operators to analyze trends, identify abnormal behavior early, and schedule maintenance before failures occur.

10. Is the probe certified for use in hazardous industrial environments?

Yes, it is available with ATEX and CSA certifications, making it suitable for explosive and high-risk industrial zones.

Bently Nevada 330103-03-10-10-11-00 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330103-03-10-10-11-00

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:1 meter

Weight:0.323 kg

Views:11

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-03-10-10-11-00 3300 XL 8mm Proximity Probe is a precision-engineered sensor specifically developed for machinery monitoring and protection systems. Part of the trusted 3300 XL series, it is widely recognized in industries such as power generation, oil & gas, petrochemical, and manufacturing. This probe operates by detecting the distance between the probe tip and a conductive target surface, typically a rotating shaft. The accurate gap measurement enables continuous monitoring of vibration, axial displacement, and rotor dynamics, ensuring early detection of machinery issues before they escalate.

The 330103-03-10-10-11-00 model is designed for high stability, long-term reliability, and compatibility with the full Bently Nevada 3300 monitoring platform. With its rugged design, stable signal transmission, and superior temperature tolerance, it ensures that critical rotating machinery operates within safe and efficient parameters.

Product Parameters

| Parameter | Specification |

|---|---|

| Product Model | Bently Nevada 330103-03-10-10-11-00 |

| Series | 3300 XL 8mm Proximity Probes |

| Probe Tip Diameter | 8 mm |

| Total Length | 1 meter |

| Weight | 0.323 kg |

| Sensitivity | -7.87 V/mm (typical) |

| Linearity Range | ± 0.076 mm (within 200 µm gap) |

| Frequency Response | DC to 10 kHz |

| Operating Gap Range | 0.25 mm to 2.0 mm |

| Compatible Proximitor | 3300 XL Proximitor Sensor |

| Cable Type | Integral coaxial cable |

| Operating Temperature | -35 °C to +180 °C |

| Storage Temperature | -50 °C to +200 °C |

| Pressure Resistance | Suitable for high-pressure sealed environments |

| Connector Type | Standard BNC or click-on connector depending on configuration |

| Certifications | CE, ATEX, CSA, and other industry-relevant standards |

Product Applications

The 330103-03-10-10-11-00 probe plays a central role in machinery health management. Its applications include:

-

Vibration Monitoring: Continuous observation of shaft vibration in turbines, compressors, and motors.

-

Axial Position Measurement: Detects rotor thrust movement to prevent mechanical damage.

-

Rotating Equipment Protection: Essential in critical equipment like gas turbines, steam turbines, pumps, and compressors.

-

Condition Monitoring: Works as a vital sensor input for predictive maintenance systems.

-

Integration with Control Systems: Directly interfaces with Bently Nevada 3300 monitoring platforms and PLC/DCS systems for automated machinery protection.

Product Advantages

-

High Accuracy and Reliability: Delivers precise measurements even in high-temperature and high-pressure environments.

-

Rugged Design: Built to withstand harsh industrial conditions, including vibration and corrosive atmospheres.

-

Wide Compatibility: Fully compatible with the 3300 XL Proximitor sensors and monitoring systems.

-

Long-Term Stability: Provides consistent performance, minimizing calibration needs.

-

Predictive Maintenance Benefits: Helps reduce unexpected shutdowns by detecting problems early.

-

Industry Proven: Trusted by industries worldwide for over three decades, making it a standard in machinery protection.

FAQ

1. How does the 330103-03-10-10-11-00 proximity probe achieve accurate displacement measurement?

It uses an eddy current principle where the probe generates an electromagnetic field that induces currents in the target surface. The variation in the return signal is directly correlated with shaft displacement, ensuring high measurement accuracy.

2. Can this probe be used interchangeably with other Bently Nevada 3300 XL probes?

Yes, as long as the probe is paired with the correct 3300 XL Proximitor sensor, it maintains calibration and ensures interchangeability within the series.

3. What is the maximum frequency range the probe can detect?

The probe supports a frequency response from DC up to 10 kHz, making it suitable for most rotating machinery vibration monitoring applications.

4. How does the probe maintain stability in high-temperature environments?

It is designed with specialized materials and insulation that allow continuous operation from -35 °C to +180 °C, ensuring reliable performance in thermal stress conditions.

5. Is the probe affected by environmental electromagnetic interference (EMI)?

No, the integral coaxial cable and shielded construction provide effective resistance to EMI, maintaining signal integrity.

6. How does the probe ensure long-term calibration accuracy?

Bently Nevada probes are manufactured with tight tolerances, and the system is factory calibrated. When paired correctly with its matching Proximitor, calibration remains stable throughout its service life.

7. Can the probe detect both static and dynamic displacements?

Yes, it can measure static shaft position (e.g., thrust movement) as well as dynamic vibration signals, providing dual functionality in machinery monitoring.

8. What role does the cable length play in probe performance?

Cable length is factory-matched and calibrated to ensure correct sensitivity and linearity. Altering cable length without recalibration can cause measurement errors.

9. How does this probe contribute to predictive maintenance strategies?

By providing real-time vibration and position data, the probe enables operators to analyze trends, identify abnormal behavior early, and schedule maintenance before failures occur.

10. Is the probe certified for use in hazardous industrial environments?

Yes, it is available with ATEX and CSA certifications, making it suitable for explosive and high-risk industrial zones.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...