Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

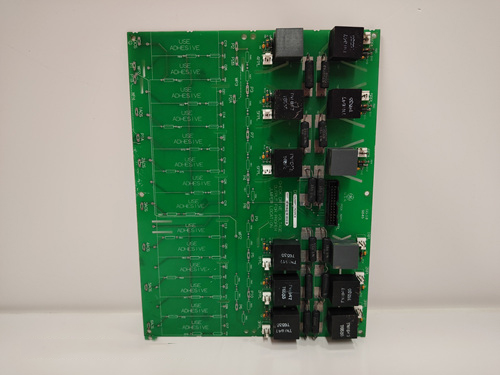

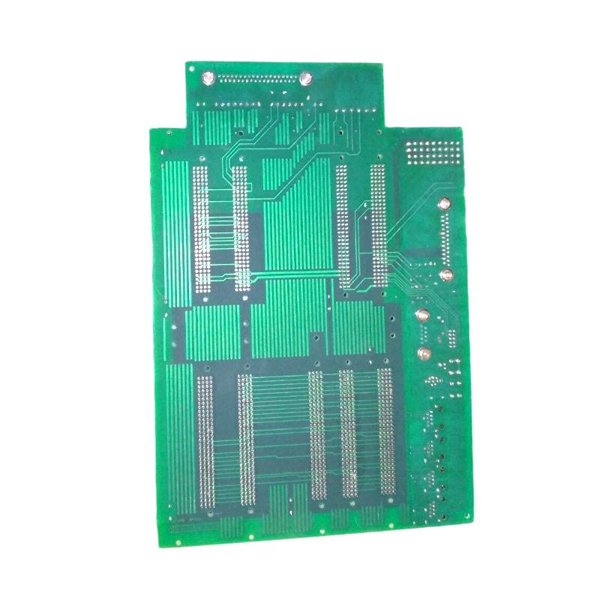

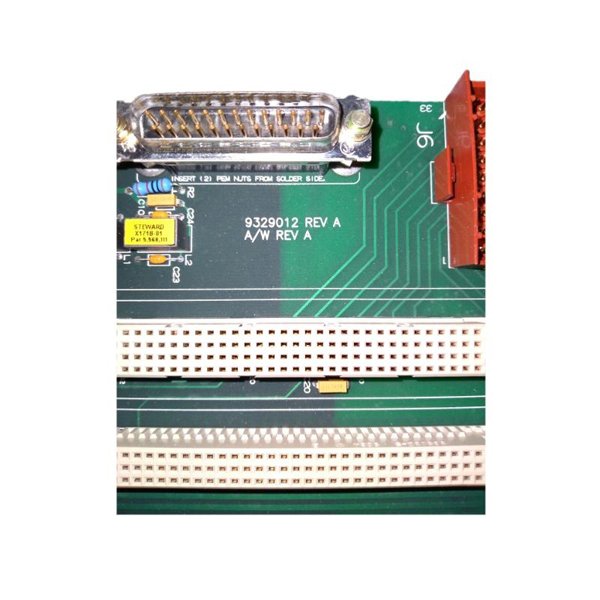

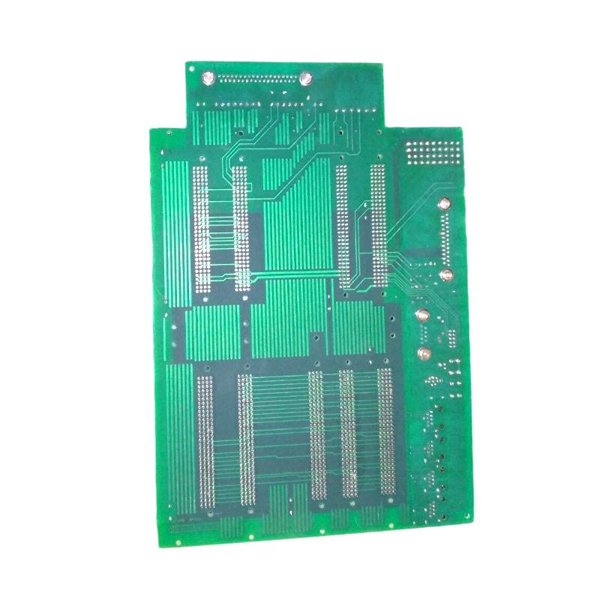

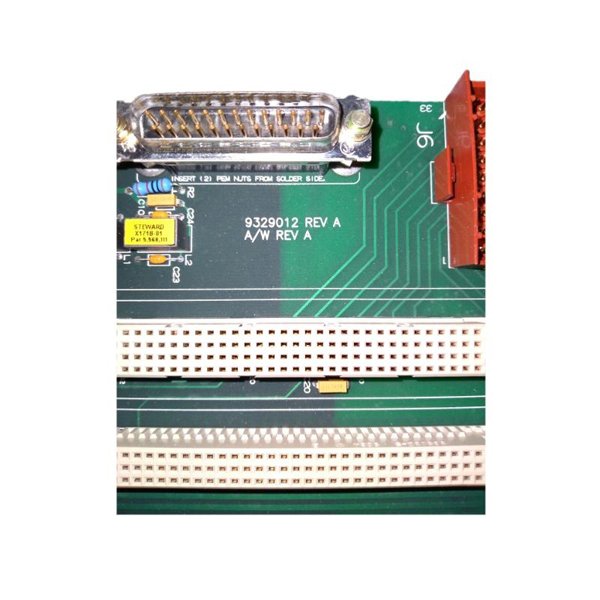

General Electric IS200CABPG1B Control Assembly Backplane Board

Manufacturer:GE

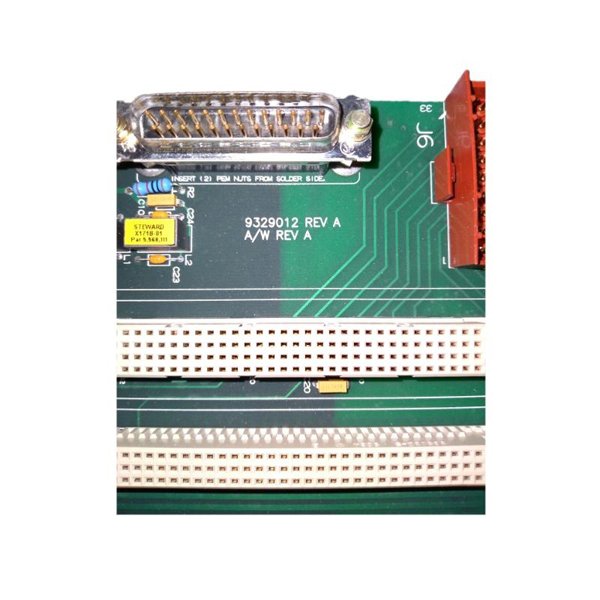

Product Number:IS200CABPG1B

Product Type:Control Assembly Backplane Board

Origin:USA

Dimensions:365 × 280 × 30 mm

Weight:1.4 kg

Views:28

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

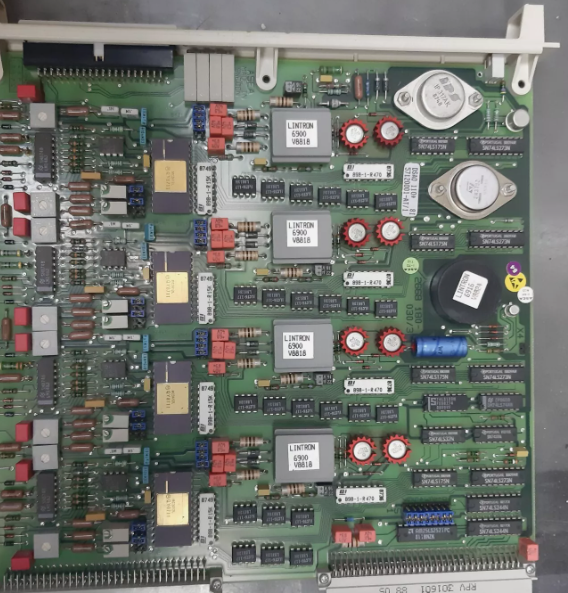

The GE IS200CABPG1B is a Control Assembly Backplane Board used in Mark VI turbine control systems, designed by GE Energy. This board functions as a crucial component within the turbine’s control cabinet, enabling high-speed signal transmission, interconnecting control modules, and organizing internal wiring through a reliable backplane structure.

The IS200CABPG1B belongs to the Mark VI platform, which is known for its modular design, high reliability, and suitability for complex industrial applications, including gas and steam turbines. This model provides the foundational hardware needed to mount and electrically connect controller modules, terminal boards, and interface components efficiently and securely.

It is built to GE’s industrial-grade specifications, ensuring operational integrity in high-temperature, high-vibration, and electromagnetically noisy environments.

Product Specifications

| Parameter | Description |

|---|---|

| Manufacturer | General Electric (GE) |

| Part Number | IS200CABPG1B |

| Product Type | Control Assembly Backplane Board |

| System Compatibility | GE Mark VI Control System |

| Function | Power distribution, control signal routing, I/O interface backplane |

| Number of Slots | Supports multiple plug-in modules such as VME and I/O cards |

| Mounting Type | Rack-mounted, cabinet installation |

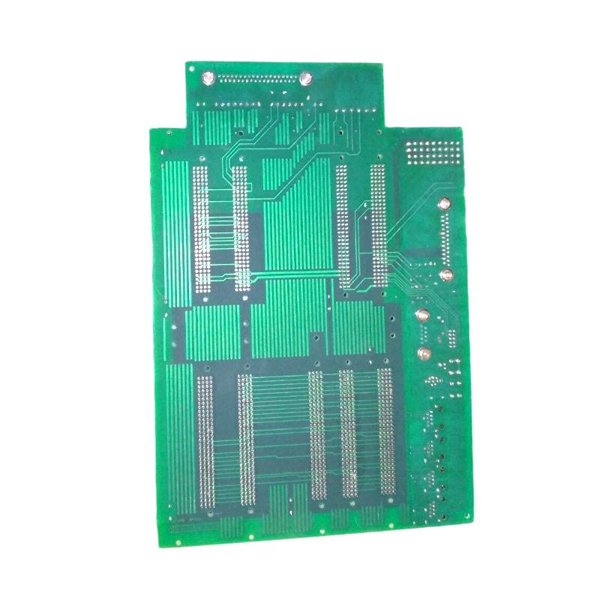

| Connectors | Multiple high-density edge connectors and ribbon cable headers |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Tolerance | 5% to 95% non-condensing |

| Dimensions | 365 × 280 × 30 mm |

| Weight | 1.4 kg |

| RoHS Compliance | Yes |

| Cooling Method | Passive, with system-integrated air flow |

Product Applications

The IS200CABPG1B board is primarily used in the following applications:

-

Gas Turbine Control Systems – Ensures real-time control coordination between turbine subsystems.

-

Steam Turbine Automation – Facilitates communication between I/O modules and processing units.

-

Generator Monitoring & Protection – Supports signal backhauling for voltage, current, and phase feedback.

-

Power Plant Distributed Control Systems (DCS) – Acts as the interface between operator modules and field instrumentation.

-

Industrial Automation Cabinets – Serves as the central interconnect board for complex automation routines.

Product Advantages

-

High Reliability: Built using GE’s rugged industrial engineering standards for uninterrupted service in harsh conditions.

-

Scalability: Supports expansion by accommodating multiple modules and I/O cards in a single backplane.

-

Efficient Layout: Reduces cabling complexity, helping technicians maintain and troubleshoot faster.

-

Passive Design: No onboard active components ensure longer service life and minimal heat generation.

-

Excellent Compatibility: Seamlessly integrates with other GE Mark VI system components.

-

Longevity: Proven field reliability of over 10+ years with proper installation and maintenance.

Frequently Asked Questions (FAQ)

1. What role does the IS200CABPG1B play in the Mark VI system?

It serves as a backplane for interconnecting control modules, enabling signal routing, power distribution, and communication between key components in the GE Mark VI control system.

2. Is this board an active processing unit?

No. The IS200CABPG1B is a passive board. It does not perform data processing but provides the essential interface structure for other active modules.

3. How is the board typically installed in the system rack?

It is mounted at the rear of a control chassis or cabinet, where it supports vertical module insertion through card-edge connectors, secured by screws or rail guides.

4. Can the IS200CABPG1B be reused with newer control modules?

Yes, as long as the new modules remain electrically and mechanically compatible with the existing backplane design, the board can be retained during system upgrades.

5. What signs might indicate a backplane board issue?

Frequent module communication errors, system boot failures, or physical damage to connectors may indicate the backplane requires inspection or replacement.

6. Does this board require firmware updates?

No. The IS200CABPG1B has no onboard firmware. All software logic resides in the connected control modules.

7. In what environments is this board typically used?

It’s primarily used in gas and steam turbine control systems, substations, and other heavy industrial automation systems where reliability and high uptime are critical.

8. How is electrical isolation handled on this board?

The board follows GE’s strict design practices, including segmented ground planes and shielding for EMI suppression, though isolation components are generally located on the connected modules.

9. What materials is the board constructed from?

It uses multilayer industrial-grade PCB material, with plated through-holes and high-density connectors designed to endure thermal and mechanical stress.

10. How long does a typical IS200CABPG1B board last in operation?

When installed in a clean, temperature-controlled cabinet, it often operates reliably for 10 to 15 years or more without needing replacement.

General Electric IS200CABPG1B Control Assembly Backplane Board

Manufacturer:GE

Product Number:IS200CABPG1B

Product Type:Control Assembly Backplane Board

Origin:USA

Dimensions:365 × 280 × 30 mm

Weight:1.4 kg

Views:28

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200CABPG1B is a Control Assembly Backplane Board used in Mark VI turbine control systems, designed by GE Energy. This board functions as a crucial component within the turbine’s control cabinet, enabling high-speed signal transmission, interconnecting control modules, and organizing internal wiring through a reliable backplane structure.

The IS200CABPG1B belongs to the Mark VI platform, which is known for its modular design, high reliability, and suitability for complex industrial applications, including gas and steam turbines. This model provides the foundational hardware needed to mount and electrically connect controller modules, terminal boards, and interface components efficiently and securely.

It is built to GE’s industrial-grade specifications, ensuring operational integrity in high-temperature, high-vibration, and electromagnetically noisy environments.

Product Specifications

| Parameter | Description |

|---|---|

| Manufacturer | General Electric (GE) |

| Part Number | IS200CABPG1B |

| Product Type | Control Assembly Backplane Board |

| System Compatibility | GE Mark VI Control System |

| Function | Power distribution, control signal routing, I/O interface backplane |

| Number of Slots | Supports multiple plug-in modules such as VME and I/O cards |

| Mounting Type | Rack-mounted, cabinet installation |

| Connectors | Multiple high-density edge connectors and ribbon cable headers |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Tolerance | 5% to 95% non-condensing |

| Dimensions | 365 × 280 × 30 mm |

| Weight | 1.4 kg |

| RoHS Compliance | Yes |

| Cooling Method | Passive, with system-integrated air flow |

Product Applications

The IS200CABPG1B board is primarily used in the following applications:

-

Gas Turbine Control Systems – Ensures real-time control coordination between turbine subsystems.

-

Steam Turbine Automation – Facilitates communication between I/O modules and processing units.

-

Generator Monitoring & Protection – Supports signal backhauling for voltage, current, and phase feedback.

-

Power Plant Distributed Control Systems (DCS) – Acts as the interface between operator modules and field instrumentation.

-

Industrial Automation Cabinets – Serves as the central interconnect board for complex automation routines.

Product Advantages

-

High Reliability: Built using GE’s rugged industrial engineering standards for uninterrupted service in harsh conditions.

-

Scalability: Supports expansion by accommodating multiple modules and I/O cards in a single backplane.

-

Efficient Layout: Reduces cabling complexity, helping technicians maintain and troubleshoot faster.

-

Passive Design: No onboard active components ensure longer service life and minimal heat generation.

-

Excellent Compatibility: Seamlessly integrates with other GE Mark VI system components.

-

Longevity: Proven field reliability of over 10+ years with proper installation and maintenance.

Frequently Asked Questions (FAQ)

1. What role does the IS200CABPG1B play in the Mark VI system?

It serves as a backplane for interconnecting control modules, enabling signal routing, power distribution, and communication between key components in the GE Mark VI control system.

2. Is this board an active processing unit?

No. The IS200CABPG1B is a passive board. It does not perform data processing but provides the essential interface structure for other active modules.

3. How is the board typically installed in the system rack?

It is mounted at the rear of a control chassis or cabinet, where it supports vertical module insertion through card-edge connectors, secured by screws or rail guides.

4. Can the IS200CABPG1B be reused with newer control modules?

Yes, as long as the new modules remain electrically and mechanically compatible with the existing backplane design, the board can be retained during system upgrades.

5. What signs might indicate a backplane board issue?

Frequent module communication errors, system boot failures, or physical damage to connectors may indicate the backplane requires inspection or replacement.

6. Does this board require firmware updates?

No. The IS200CABPG1B has no onboard firmware. All software logic resides in the connected control modules.

7. In what environments is this board typically used?

It’s primarily used in gas and steam turbine control systems, substations, and other heavy industrial automation systems where reliability and high uptime are critical.

8. How is electrical isolation handled on this board?

The board follows GE’s strict design practices, including segmented ground planes and shielding for EMI suppression, though isolation components are generally located on the connected modules.

9. What materials is the board constructed from?

It uses multilayer industrial-grade PCB material, with plated through-holes and high-density connectors designed to endure thermal and mechanical stress.

10. How long does a typical IS200CABPG1B board last in operation?

When installed in a clean, temperature-controlled cabinet, it often operates reliably for 10 to 15 years or more without needing replacement.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...