Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

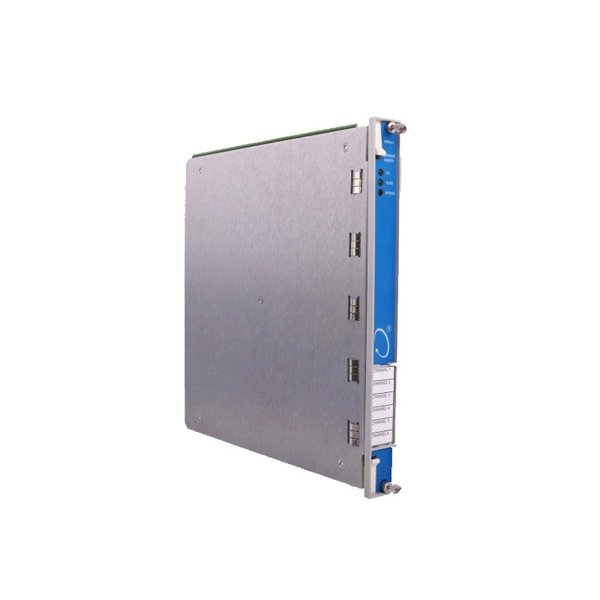

Bently Nevada 3500/42 176449-02 Proximitor Seismic I/O Module

Manufacturer:Bently Nevada

Product Number:3500/42 176449-02

Product Type:Proximitor Seismic I/O Module

Origin:USA

Dimensions:241.3 x 24.4 x 163.1mm

Weight :0.46 kg

Views:81

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The 3500/42 176449-02 is engineered to operate under harsh conditions, offering exceptional stability, accuracy, and longevity. Its robust design ensures it can withstand high vibration, temperature variations, and electromagnetic interference, making it suitable for power generation, petrochemical, and heavy manufacturing plants.

This module integrates seamlessly into the 3500 Series monitoring system, allowing operators to obtain precise vibration readings, enabling timely maintenance decisions and reducing unscheduled downtime.

Product Advantages

-

High Precision: Provides accurate seismic measurements with minimal drift over time.

-

Reliable Protection: Rapid detection of machinery vibration anomalies to prevent catastrophic failures.

-

Durable Design: Built to endure harsh industrial environments, including high vibration and temperature fluctuations.

-

Seamless Integration: Compatible with all 3500 Series modules for synchronized monitoring.

-

Real-Time Monitoring: Enables proactive maintenance through continuous, real-time vibration data.

-

User-Friendly Diagnostics: Supports easy troubleshooting and calibration via standard tools and system interfaces.

-

Enhanced Safety: Protects critical assets and personnel by providing early warnings of mechanical issues.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3500/42 176449-02 |

| Function | Proximitor Seismic Monitor |

| Dimensions | 241.3 x 24.4 x 163.1mm |

| Weight | 0.46 kg |

| Input Voltage | 24 VDC ± 10% |

| Current Consumption | 200 mA typical |

| Temperature Range | -20°C to 70°C operational |

| Humidity | 5% – 95% non-condensing |

| Mounting Type | Rack-mounted, 19-inch 4U |

| Signal Outputs | 4–20 mA, ±10 V analog |

| Alarm Outputs | Relay-based configurable alarms |

| Response Frequency | 0.5 Hz – 1 kHz |

| Compliance | CE, UL, CSA standards |

Product Applications

The 3500/42 176449-02 is primarily used in applications where precise seismic monitoring is critical. Typical applications include:

-

Power Generation: Steam, gas, and hydro turbines, generators, and auxiliary machinery.

-

Petrochemical Plants: Compressors, pumps, and rotating equipment requiring early fault detection.

-

Industrial Manufacturing: Critical rotating machinery in steel mills, paper plants, and chemical facilities.

-

Oil & Gas: Offshore and onshore machinery monitoring for early detection of structural vibrations.

-

Aerospace & Defense: High-performance rotating equipment requiring exact vibration control.

Frequently Asked Questions (FAQ)

Q1: What type of sensors does the 3500/42 176449-02 support?

A1: It supports Proximitor-style eddy current displacement probes and seismic transducers compatible with the 3500 Series.

Q2: Can it operate in high-temperature environments?

A2: Yes, the unit is designed to operate reliably in environments ranging from -20°C to 70°C.

Q3: How is the module integrated into the 3500 Series system?

A3: It mounts in a standard 19-inch 4U rack and communicates with other 3500 Series modules via the system backplane.

Q4: What type of alarms does it provide?

A4: The module offers relay-based configurable alarms, including high vibration, surge, and equipment trip alarms.

Q5: Is calibration required?

A5: Yes, periodic calibration using standard Bently Nevada calibration tools ensures accurate readings.

Q6: Can it be used for continuous monitoring?

A6: Absolutely, the module is designed for 24/7 continuous vibration monitoring.

Q7: What happens if the module fails?

A7: The system provides a fail-safe mechanism and redundancy options to prevent machinery damage.

Q8: What communication outputs are available?

A8: The module provides analog outputs (4–20 mA, ±10 V) for data logging and control systems.

Q9: Is it compatible with older 3500 Series modules?

A9: Yes, it is fully backward compatible with previous 3500 Series hardware.

Q10: How do I maintain the module?

A10: Regular visual inspections, proper rack ventilation, and periodic calibration are recommended.

Bently Nevada 3500/42 176449-02 Proximitor Seismic I/O Module

Manufacturer:Bently Nevada

Product Number:3500/42 176449-02

Product Type:Proximitor Seismic I/O Module

Origin:USA

Dimensions:241.3 x 24.4 x 163.1mm

Weight :0.46 kg

Views:81

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The 3500/42 176449-02 is engineered to operate under harsh conditions, offering exceptional stability, accuracy, and longevity. Its robust design ensures it can withstand high vibration, temperature variations, and electromagnetic interference, making it suitable for power generation, petrochemical, and heavy manufacturing plants.

This module integrates seamlessly into the 3500 Series monitoring system, allowing operators to obtain precise vibration readings, enabling timely maintenance decisions and reducing unscheduled downtime.

Product Advantages

-

High Precision: Provides accurate seismic measurements with minimal drift over time.

-

Reliable Protection: Rapid detection of machinery vibration anomalies to prevent catastrophic failures.

-

Durable Design: Built to endure harsh industrial environments, including high vibration and temperature fluctuations.

-

Seamless Integration: Compatible with all 3500 Series modules for synchronized monitoring.

-

Real-Time Monitoring: Enables proactive maintenance through continuous, real-time vibration data.

-

User-Friendly Diagnostics: Supports easy troubleshooting and calibration via standard tools and system interfaces.

-

Enhanced Safety: Protects critical assets and personnel by providing early warnings of mechanical issues.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3500/42 176449-02 |

| Function | Proximitor Seismic Monitor |

| Dimensions | 241.3 x 24.4 x 163.1mm |

| Weight | 0.46 kg |

| Input Voltage | 24 VDC ± 10% |

| Current Consumption | 200 mA typical |

| Temperature Range | -20°C to 70°C operational |

| Humidity | 5% – 95% non-condensing |

| Mounting Type | Rack-mounted, 19-inch 4U |

| Signal Outputs | 4–20 mA, ±10 V analog |

| Alarm Outputs | Relay-based configurable alarms |

| Response Frequency | 0.5 Hz – 1 kHz |

| Compliance | CE, UL, CSA standards |

Product Applications

The 3500/42 176449-02 is primarily used in applications where precise seismic monitoring is critical. Typical applications include:

-

Power Generation: Steam, gas, and hydro turbines, generators, and auxiliary machinery.

-

Petrochemical Plants: Compressors, pumps, and rotating equipment requiring early fault detection.

-

Industrial Manufacturing: Critical rotating machinery in steel mills, paper plants, and chemical facilities.

-

Oil & Gas: Offshore and onshore machinery monitoring for early detection of structural vibrations.

-

Aerospace & Defense: High-performance rotating equipment requiring exact vibration control.

Frequently Asked Questions (FAQ)

Q1: What type of sensors does the 3500/42 176449-02 support?

A1: It supports Proximitor-style eddy current displacement probes and seismic transducers compatible with the 3500 Series.

Q2: Can it operate in high-temperature environments?

A2: Yes, the unit is designed to operate reliably in environments ranging from -20°C to 70°C.

Q3: How is the module integrated into the 3500 Series system?

A3: It mounts in a standard 19-inch 4U rack and communicates with other 3500 Series modules via the system backplane.

Q4: What type of alarms does it provide?

A4: The module offers relay-based configurable alarms, including high vibration, surge, and equipment trip alarms.

Q5: Is calibration required?

A5: Yes, periodic calibration using standard Bently Nevada calibration tools ensures accurate readings.

Q6: Can it be used for continuous monitoring?

A6: Absolutely, the module is designed for 24/7 continuous vibration monitoring.

Q7: What happens if the module fails?

A7: The system provides a fail-safe mechanism and redundancy options to prevent machinery damage.

Q8: What communication outputs are available?

A8: The module provides analog outputs (4–20 mA, ±10 V) for data logging and control systems.

Q9: Is it compatible with older 3500 Series modules?

A9: Yes, it is fully backward compatible with previous 3500 Series hardware.

Q10: How do I maintain the module?

A10: Regular visual inspections, proper rack ventilation, and periodic calibration are recommended.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...