Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

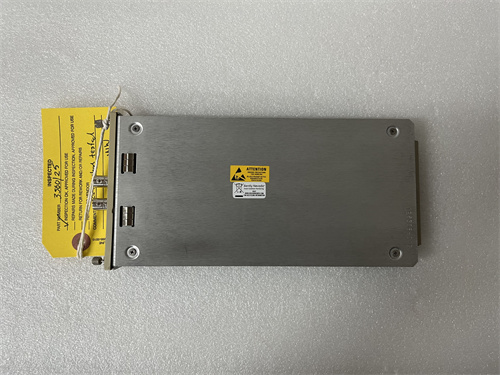

Bently Nevada 330704-000-050-90-02 3300 XL 11 mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330704-000-050-90-02

Product Type:3300 XL 11 mm Proximity Probes

Origin:USA

Total Length:9 meters

Weight:1.29 kg

Views:12

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330704-000-050-90-02 3300 XL 11 mm Proximity Probe is a premium non-contact displacement sensor engineered for continuous monitoring of shaft vibration and rotor position in mission-critical rotating equipment. Designed as part of the industry-trusted 3300 XL family, this probe offers outstanding measurement accuracy, excellent linearity, and robust thermal stability. Its rugged stainless-steel housing and advanced electromagnetic shielding enable long-term operation in harsh industrial environments such as power generation, petrochemical processing, and heavy manufacturing. The probe integrates seamlessly with 3300 XL Proximitor® sensors, delivering precise data for predictive maintenance and protection systems that safeguard turbines, compressors, pumps, and motors.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 330704-000-050-90-02 |

| Series | 3300 XL Proximity Probes |

| Measurement Range | 11 mm non-contact displacement |

| Sensitivity | 5 mV/µm nominal |

| Frequency Response | DC to 10 kHz |

| Linearity | ±1 % of full scale |

| Operating Temperature | –40 °C to +120 °C |

| Insulation Resistance | >100 MΩ at 500 V DC |

| Dielectric Strength | 2.5 kV AC for 1 minute |

| Housing Material | Stainless steel |

| Probe Tip Material | High-density ceramic |

| Shock/Vibration Rating | Up to 20 g, 10–2000 Hz |

| Output Compatibility | Compatible with Bently Nevada 3300 XL Proximitor® sensors |

| Mounting Style | Precision threaded mounting |

| Total Length | 9.0 meters |

| Weight | 1.29 kg |

Applications

-

Turbomachinery Monitoring – Accurate real-time detection of shaft vibration and rotor position in steam, gas, and hydro turbines.

-

Compressors and Pumps – Early warning of bearing wear, imbalance, or misalignment in critical process equipment.

-

Power Generation Systems – Continuous condition monitoring of generators and high-speed motors.

-

Petrochemical and Refinery Equipment – Reliable operation in high-temperature, high-vibration environments.

-

Industrial Fans and Blowers – Ideal for heavy-duty rotating machinery requiring precision displacement measurement.

-

System Integration – Drop-in compatibility with existing 3300 XL monitoring and protection systems.

Advantages

-

High Measurement Precision – Maintains ±1 % linearity for dependable displacement and vibration data.

-

Robust Mechanical Design – Stainless-steel housing and ceramic tip resist corrosion, abrasion, and thermal cycling.

-

Outstanding EMI Protection – Advanced shielding ensures clean signals in electrically noisy facilities.

-

Predictive Maintenance Ready – Supports early detection of mechanical faults, reducing unplanned downtime.

-

Proven Reliability – 3300 XL technology ensures consistent performance in continuous 24/7 operation.

-

Seamless Compatibility – Fully calibrated for direct connection to 3300 XL Proximitor® sensors without additional adjustments.

Frequently Asked Questions (FAQ)

-

What sensing principle does this probe use?

It operates on an eddy-current principle to measure the gap between the probe tip and the shaft surface.

-

Is it factory-calibrated for the 3300 XL Proximitor®?

Yes, the probe is pre-calibrated for direct connection to 3300 XL Proximitor® sensors.

-

What is the nominal sensitivity rating?

The output provides approximately 5 mV/µm for accurate vibration and displacement monitoring.

-

Does the probe require recalibration after installation?

Only basic system verification is typically required; no field recalibration is necessary.

-

How does it perform under high vibration levels?

It withstands up to 20 g across the 10–2000 Hz range without signal degradation.

-

What target material ensures best measurement accuracy?

Conductive ferromagnetic materials such as steel provide optimal results.

-

Is it suitable for continuous 24/7 monitoring?

Yes, it is designed for permanent installation in critical machinery requiring constant surveillance.

-

What is the frequency response range?

The probe delivers accurate data from DC up to 10 kHz, ideal for dynamic vibration measurement.

-

Can the probe detect both radial and axial displacement?

Yes, depending on installation orientation it can measure either radial or axial shaft movement.

-

How is electromagnetic interference minimized?

Multi-layer shielding and precision grounding techniques reduce EMI for stable signal output.

Bently Nevada 330704-000-050-90-02 3300 XL 11 mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330704-000-050-90-02

Product Type:3300 XL 11 mm Proximity Probes

Origin:USA

Total Length:9 meters

Weight:1.29 kg

Views:12

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330704-000-050-90-02 3300 XL 11 mm Proximity Probe is a premium non-contact displacement sensor engineered for continuous monitoring of shaft vibration and rotor position in mission-critical rotating equipment. Designed as part of the industry-trusted 3300 XL family, this probe offers outstanding measurement accuracy, excellent linearity, and robust thermal stability. Its rugged stainless-steel housing and advanced electromagnetic shielding enable long-term operation in harsh industrial environments such as power generation, petrochemical processing, and heavy manufacturing. The probe integrates seamlessly with 3300 XL Proximitor® sensors, delivering precise data for predictive maintenance and protection systems that safeguard turbines, compressors, pumps, and motors.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 330704-000-050-90-02 |

| Series | 3300 XL Proximity Probes |

| Measurement Range | 11 mm non-contact displacement |

| Sensitivity | 5 mV/µm nominal |

| Frequency Response | DC to 10 kHz |

| Linearity | ±1 % of full scale |

| Operating Temperature | –40 °C to +120 °C |

| Insulation Resistance | >100 MΩ at 500 V DC |

| Dielectric Strength | 2.5 kV AC for 1 minute |

| Housing Material | Stainless steel |

| Probe Tip Material | High-density ceramic |

| Shock/Vibration Rating | Up to 20 g, 10–2000 Hz |

| Output Compatibility | Compatible with Bently Nevada 3300 XL Proximitor® sensors |

| Mounting Style | Precision threaded mounting |

| Total Length | 9.0 meters |

| Weight | 1.29 kg |

Applications

-

Turbomachinery Monitoring – Accurate real-time detection of shaft vibration and rotor position in steam, gas, and hydro turbines.

-

Compressors and Pumps – Early warning of bearing wear, imbalance, or misalignment in critical process equipment.

-

Power Generation Systems – Continuous condition monitoring of generators and high-speed motors.

-

Petrochemical and Refinery Equipment – Reliable operation in high-temperature, high-vibration environments.

-

Industrial Fans and Blowers – Ideal for heavy-duty rotating machinery requiring precision displacement measurement.

-

System Integration – Drop-in compatibility with existing 3300 XL monitoring and protection systems.

Advantages

-

High Measurement Precision – Maintains ±1 % linearity for dependable displacement and vibration data.

-

Robust Mechanical Design – Stainless-steel housing and ceramic tip resist corrosion, abrasion, and thermal cycling.

-

Outstanding EMI Protection – Advanced shielding ensures clean signals in electrically noisy facilities.

-

Predictive Maintenance Ready – Supports early detection of mechanical faults, reducing unplanned downtime.

-

Proven Reliability – 3300 XL technology ensures consistent performance in continuous 24/7 operation.

-

Seamless Compatibility – Fully calibrated for direct connection to 3300 XL Proximitor® sensors without additional adjustments.

Frequently Asked Questions (FAQ)

-

What sensing principle does this probe use?

It operates on an eddy-current principle to measure the gap between the probe tip and the shaft surface.

-

Is it factory-calibrated for the 3300 XL Proximitor®?

Yes, the probe is pre-calibrated for direct connection to 3300 XL Proximitor® sensors.

-

What is the nominal sensitivity rating?

The output provides approximately 5 mV/µm for accurate vibration and displacement monitoring.

-

Does the probe require recalibration after installation?

Only basic system verification is typically required; no field recalibration is necessary.

-

How does it perform under high vibration levels?

It withstands up to 20 g across the 10–2000 Hz range without signal degradation.

-

What target material ensures best measurement accuracy?

Conductive ferromagnetic materials such as steel provide optimal results.

-

Is it suitable for continuous 24/7 monitoring?

Yes, it is designed for permanent installation in critical machinery requiring constant surveillance.

-

What is the frequency response range?

The probe delivers accurate data from DC up to 10 kHz, ideal for dynamic vibration measurement.

-

Can the probe detect both radial and axial displacement?

Yes, depending on installation orientation it can measure either radial or axial shaft movement.

-

How is electromagnetic interference minimized?

Multi-layer shielding and precision grounding techniques reduce EMI for stable signal output.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...