Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

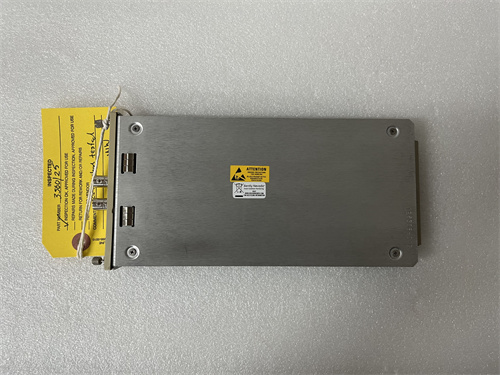

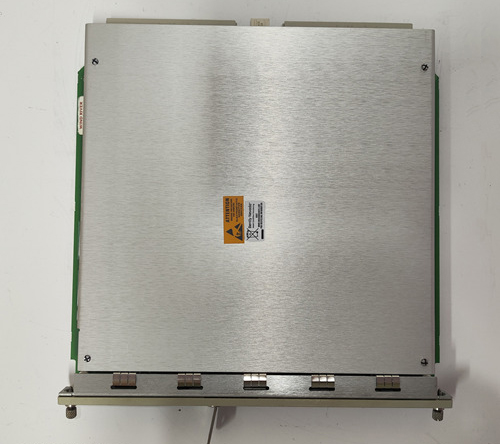

Bently Nevada 330103-00-14-10-12-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-00-14-10-12-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:1.0 meter

Weight:0.323 kg

Views:25

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-00-14-10-12-05 is part of the 3300 XL 8 mm proximity probe series, engineered for reliable vibration and displacement measurement in rotating machinery. This probe provides precise non-contact measurement using eddy-current technology, delivering a linear voltage output proportional to the distance from a conductive target surface. Built with robust stainless steel housing, FluidLoc cable, and ClickLoc connectors, it ensures stable operation in demanding industrial environments and complies with API 670 standards.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 330103-00-14-10-12-05 |

| Thread Type | M10 × 1, unarmored |

| Case/Unthreaded Length | Option “14” (specific length defined in system configuration) |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Connector Type | Miniature ClickLoc with FluidLoc cable |

| Probe Tip Material | Polyphenylene Sulfide (PPS) |

| Case Material | Stainless Steel (AISI 303/304) |

| Sealing | Viton® O-ring differential pressure seal |

| Hazardous Area Approvals | CSA, ATEX, IECEx |

| System Compliance | API 670 (4th Edition) |

| Interchangeability | Fully compatible with 3300 XL extension cables and Proximitor® sensors |

Applications

-

Vibration monitoring in steam turbines, gas turbines, and compressors

-

Shaft position and radial vibration measurement in rotating machinery

-

Thrust position monitoring in large turbomachinery

-

Bearing health monitoring for predictive maintenance

-

High-reliability condition monitoring in hazardous industrial environments

Advantages

-

High Accuracy: Delivers precise measurements with API 670 compliance.

-

Rugged Construction: Stainless steel housing and PPS tip ensure durability.

-

Interchangeability: Compatible with other 3300 XL probes, sensors, and extension cables.

-

Enhanced Reliability: FluidLoc cable reduces contamination ingress, improving long-term stability.

-

Hazardous Area Certification: Suitable for installation in CSA, ATEX, and IECEx classified areas.

-

Maintenance Efficiency: ClickLoc connectors allow secure and quick connections.

FAQ

Q1: What is the primary function of the 330103-00-14-10-12-05 probe?

A1: It measures shaft vibration and position by converting displacement into a proportional voltage signal.

Q2: How does it differ from the armored 330104 version?

A2: The 330103 is unarmored, while the 330104 includes stainless steel armor for cable protection.

Q3: Is this probe compliant with API 670?

A3: Yes, it meets API 670 (4th Edition) requirements for linear range, accuracy, and mechanical design.

Q4: Can it be mixed with other 3300 XL probes and sensors?

A4: Yes, the probe is fully interchangeable with other 3300 XL system components without recalibration.

Q5: What environments is this probe suitable for?

A5: It is certified for hazardous areas with CSA, ATEX, and IECEx approvals.

Q6: How does the FluidLoc cable improve performance?

A6: The FluidLoc design prevents moisture ingress, ensuring measurement stability and reducing failures.

Q7: What is the typical linear range of this probe?

A7: The 8 mm probe typically provides a linear range of up to 2 mm with high accuracy.

Q8: How is the probe installed on machinery?

A8: It uses an M10 × 1 threaded case for mounting, with optional mounting brackets or housings.

Q9: What materials are used in construction?

A9: Stainless steel case (AISI 303/304), PPS tip, and Viton® O-ring sealing.

Q10: Does it require periodic recalibration?

A10: No, when used with compatible Bently Nevada Proximitor® sensors and extension cables, no recalibration is needed.

Bently Nevada 330103-00-14-10-12-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-00-14-10-12-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:1.0 meter

Weight:0.323 kg

Views:25

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-00-14-10-12-05 is part of the 3300 XL 8 mm proximity probe series, engineered for reliable vibration and displacement measurement in rotating machinery. This probe provides precise non-contact measurement using eddy-current technology, delivering a linear voltage output proportional to the distance from a conductive target surface. Built with robust stainless steel housing, FluidLoc cable, and ClickLoc connectors, it ensures stable operation in demanding industrial environments and complies with API 670 standards.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 330103-00-14-10-12-05 |

| Thread Type | M10 × 1, unarmored |

| Case/Unthreaded Length | Option “14” (specific length defined in system configuration) |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Connector Type | Miniature ClickLoc with FluidLoc cable |

| Probe Tip Material | Polyphenylene Sulfide (PPS) |

| Case Material | Stainless Steel (AISI 303/304) |

| Sealing | Viton® O-ring differential pressure seal |

| Hazardous Area Approvals | CSA, ATEX, IECEx |

| System Compliance | API 670 (4th Edition) |

| Interchangeability | Fully compatible with 3300 XL extension cables and Proximitor® sensors |

Applications

-

Vibration monitoring in steam turbines, gas turbines, and compressors

-

Shaft position and radial vibration measurement in rotating machinery

-

Thrust position monitoring in large turbomachinery

-

Bearing health monitoring for predictive maintenance

-

High-reliability condition monitoring in hazardous industrial environments

Advantages

-

High Accuracy: Delivers precise measurements with API 670 compliance.

-

Rugged Construction: Stainless steel housing and PPS tip ensure durability.

-

Interchangeability: Compatible with other 3300 XL probes, sensors, and extension cables.

-

Enhanced Reliability: FluidLoc cable reduces contamination ingress, improving long-term stability.

-

Hazardous Area Certification: Suitable for installation in CSA, ATEX, and IECEx classified areas.

-

Maintenance Efficiency: ClickLoc connectors allow secure and quick connections.

FAQ

Q1: What is the primary function of the 330103-00-14-10-12-05 probe?

A1: It measures shaft vibration and position by converting displacement into a proportional voltage signal.

Q2: How does it differ from the armored 330104 version?

A2: The 330103 is unarmored, while the 330104 includes stainless steel armor for cable protection.

Q3: Is this probe compliant with API 670?

A3: Yes, it meets API 670 (4th Edition) requirements for linear range, accuracy, and mechanical design.

Q4: Can it be mixed with other 3300 XL probes and sensors?

A4: Yes, the probe is fully interchangeable with other 3300 XL system components without recalibration.

Q5: What environments is this probe suitable for?

A5: It is certified for hazardous areas with CSA, ATEX, and IECEx approvals.

Q6: How does the FluidLoc cable improve performance?

A6: The FluidLoc design prevents moisture ingress, ensuring measurement stability and reducing failures.

Q7: What is the typical linear range of this probe?

A7: The 8 mm probe typically provides a linear range of up to 2 mm with high accuracy.

Q8: How is the probe installed on machinery?

A8: It uses an M10 × 1 threaded case for mounting, with optional mounting brackets or housings.

Q9: What materials are used in construction?

A9: Stainless steel case (AISI 303/304), PPS tip, and Viton® O-ring sealing.

Q10: Does it require periodic recalibration?

A10: No, when used with compatible Bently Nevada Proximitor® sensors and extension cables, no recalibration is needed.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...