Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

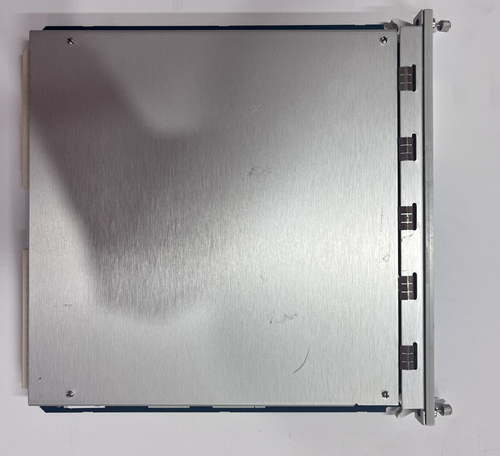

Bently Nevada 3500/42M 135489-03 I/O Module

Manufacturer:Bently Nevada

Product Number:3500/42M 135489-03

Product Type:I/O Module

Origin:USA

Dimensions:241.3 x 24.4 x 163.1 mm

Weight :0.46 kg

Views:38

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42M 135489-03 is a Proximitor/Seismic Monitor I/O Module designed for vibration monitoring systems widely used in critical rotating machinery health monitoring. As part of the Bently Nevada 3500 Series machinery protection system, this module provides precise measurement and monitoring of seismic and proximity sensor inputs, enabling early detection of potentially damaging conditions such as vibrations, misalignments, or bearing faults.

This module integrates seamlessly into large-scale vibration monitoring architectures, offering reliable data acquisition and communication capabilities essential for industrial plants, power generation stations, and heavy machinery maintenance programs. It enhances asset protection by delivering accurate real-time information, helping maintenance teams to prevent unexpected downtime and costly repairs.

Product Advantages

-

High Reliability: Built to operate under harsh industrial environments with robust protection against electrical noise and environmental disturbances.

-

Modular Design: Fits into the 3500 rack system, allowing easy expansion and maintenance without disrupting ongoing operations.

-

Accurate Data Acquisition: Supports Proximitor and seismic sensors with precise signal processing for early fault detection.

-

Flexible Interface: Compatible with multiple signal types and able to integrate into different monitoring architectures.

-

Reduced Downtime: Enables predictive maintenance strategies through continuous monitoring and alarm generation.

-

Industry Proven: Trusted worldwide in power plants, petrochemical, and manufacturing industries for decades.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3500/42M 135489-03 |

| Function | Proximitor / Seismic Monitor I/O Module |

| Dimensions | 241.3 x 24.4 x 163.1 mm |

| Weight | 0.46 kg |

| Power Supply | Supplied from 3500 rack chassis |

| Input Signal Types | Proximity, Seismic sensors |

| Output Signals | Processed vibration/seismic signals to rack bus |

| Operating Temperature | -40 °C to +75 °C |

| Storage Temperature | -55 °C to +85 °C |

| Humidity | 5% to 95%, non-condensing |

| Mounting | 3500 Series Rack Mount |

| Communication Interface | 3500 rack backplane bus |

Product Applications

-

Continuous vibration monitoring of rotating equipment such as turbines, compressors, pumps, and generators.

-

Seismic event detection and monitoring for equipment sensitive to shock and structural vibrations.

-

Integration into machinery protection systems for early warning and alarm functions.

-

Industrial facilities including power generation plants, oil and gas refineries, petrochemical plants, and heavy manufacturing.

-

Predictive maintenance programs to optimize machinery uptime and reduce unplanned outages.

-

Monitoring of critical asset health to support reliability-centered maintenance (RCM).

Frequently Asked Questions (FAQ)

Q1: What types of sensors can the 3500/42M module interface with?

A1: The module supports Proximitor proximity probes and seismic sensors, allowing it to monitor shaft vibration and seismic events effectively.

Q2: How is the module powered?

A2: It receives power directly from the 3500 Series rack chassis, eliminating the need for separate power supplies.

Q3: Can the 3500/42M module be used in high-temperature environments?

A3: Yes, it is rated to operate in temperatures from -40°C to +75°C, suitable for many industrial environments.

Q4: How does this module communicate data to the monitoring system?

A4: It communicates via the 3500 rack backplane bus, which connects to the central monitoring processor.

Q5: Is the module easy to install and maintain?

A5: Yes, the modular rack design allows for simple plug-in installation and removal without system shutdown.

Q6: What maintenance is required for this module?

A6: Generally, routine visual inspection and cleaning are sufficient; internal calibration or repair should be performed by qualified technicians.

Q7: Does this module provide alarm functions?

A7: Yes, it supports alarm generation based on vibration or seismic threshold limits configured in the monitoring system.

Q8: What is the expected lifespan of the 3500/42M module?

A8: With proper care and operation within specifications, the module typically operates reliably for over 5 years.

Q9: Can this module handle multiple sensor inputs?

A9: It is designed to process signals from specific Proximitor or seismic sensors; the exact number depends on system configuration.

Q10: Are replacement parts readily available?

A10: Yes, Bently Nevada provides ongoing support with replacement modules and parts through authorized distributors.

Bently Nevada 3500/42M 135489-03 I/O Module

Manufacturer:Bently Nevada

Product Number:3500/42M 135489-03

Product Type:I/O Module

Origin:USA

Dimensions:241.3 x 24.4 x 163.1 mm

Weight :0.46 kg

Views:38

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42M 135489-03 is a Proximitor/Seismic Monitor I/O Module designed for vibration monitoring systems widely used in critical rotating machinery health monitoring. As part of the Bently Nevada 3500 Series machinery protection system, this module provides precise measurement and monitoring of seismic and proximity sensor inputs, enabling early detection of potentially damaging conditions such as vibrations, misalignments, or bearing faults.

This module integrates seamlessly into large-scale vibration monitoring architectures, offering reliable data acquisition and communication capabilities essential for industrial plants, power generation stations, and heavy machinery maintenance programs. It enhances asset protection by delivering accurate real-time information, helping maintenance teams to prevent unexpected downtime and costly repairs.

Product Advantages

-

High Reliability: Built to operate under harsh industrial environments with robust protection against electrical noise and environmental disturbances.

-

Modular Design: Fits into the 3500 rack system, allowing easy expansion and maintenance without disrupting ongoing operations.

-

Accurate Data Acquisition: Supports Proximitor and seismic sensors with precise signal processing for early fault detection.

-

Flexible Interface: Compatible with multiple signal types and able to integrate into different monitoring architectures.

-

Reduced Downtime: Enables predictive maintenance strategies through continuous monitoring and alarm generation.

-

Industry Proven: Trusted worldwide in power plants, petrochemical, and manufacturing industries for decades.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3500/42M 135489-03 |

| Function | Proximitor / Seismic Monitor I/O Module |

| Dimensions | 241.3 x 24.4 x 163.1 mm |

| Weight | 0.46 kg |

| Power Supply | Supplied from 3500 rack chassis |

| Input Signal Types | Proximity, Seismic sensors |

| Output Signals | Processed vibration/seismic signals to rack bus |

| Operating Temperature | -40 °C to +75 °C |

| Storage Temperature | -55 °C to +85 °C |

| Humidity | 5% to 95%, non-condensing |

| Mounting | 3500 Series Rack Mount |

| Communication Interface | 3500 rack backplane bus |

Product Applications

-

Continuous vibration monitoring of rotating equipment such as turbines, compressors, pumps, and generators.

-

Seismic event detection and monitoring for equipment sensitive to shock and structural vibrations.

-

Integration into machinery protection systems for early warning and alarm functions.

-

Industrial facilities including power generation plants, oil and gas refineries, petrochemical plants, and heavy manufacturing.

-

Predictive maintenance programs to optimize machinery uptime and reduce unplanned outages.

-

Monitoring of critical asset health to support reliability-centered maintenance (RCM).

Frequently Asked Questions (FAQ)

Q1: What types of sensors can the 3500/42M module interface with?

A1: The module supports Proximitor proximity probes and seismic sensors, allowing it to monitor shaft vibration and seismic events effectively.

Q2: How is the module powered?

A2: It receives power directly from the 3500 Series rack chassis, eliminating the need for separate power supplies.

Q3: Can the 3500/42M module be used in high-temperature environments?

A3: Yes, it is rated to operate in temperatures from -40°C to +75°C, suitable for many industrial environments.

Q4: How does this module communicate data to the monitoring system?

A4: It communicates via the 3500 rack backplane bus, which connects to the central monitoring processor.

Q5: Is the module easy to install and maintain?

A5: Yes, the modular rack design allows for simple plug-in installation and removal without system shutdown.

Q6: What maintenance is required for this module?

A6: Generally, routine visual inspection and cleaning are sufficient; internal calibration or repair should be performed by qualified technicians.

Q7: Does this module provide alarm functions?

A7: Yes, it supports alarm generation based on vibration or seismic threshold limits configured in the monitoring system.

Q8: What is the expected lifespan of the 3500/42M module?

A8: With proper care and operation within specifications, the module typically operates reliably for over 5 years.

Q9: Can this module handle multiple sensor inputs?

A9: It is designed to process signals from specific Proximitor or seismic sensors; the exact number depends on system configuration.

Q10: Are replacement parts readily available?

A10: Yes, Bently Nevada provides ongoing support with replacement modules and parts through authorized distributors.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...