Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

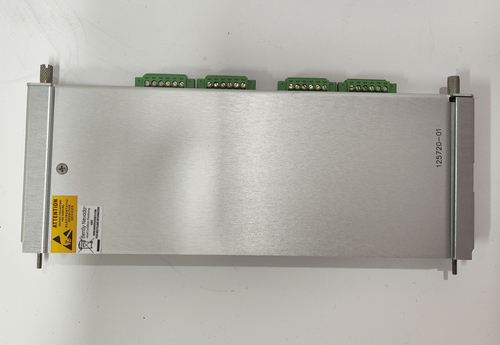

Bently Nevada 330901-00-16-10-11-CN 3300 NSv Proximity Probe

Manufacturer:Bently Nevada

Product Number:330901-00-16-10-11-CN

Product Type:3300 NSv Proximity Probe

Origin:USA

Dimensions:1m

Weight :3 kg

Views:11

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330901-00-16-10-11-CN 3300 NSv Proximity Probe is a precision-engineered probe designed for use in the 3300 NSv (Narrow Side View) proximity measurement system. It provides accurate, reliable measurements of shaft vibration and position in machinery where space constraints exist. This probe is tailored for applications with limited installation clearance, offering dependable performance in demanding industrial environments such as turbines, compressors, pumps, and rotating machinery.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | 330901-00-16-10-11-CN |

| Series | 3300 NSv Proximity Probe |

| Connector Type | Standard Bently Nevada coaxial connector |

| Probe Material | Stainless steel body with ceramic tip |

| Operating Temperature | -35°C to +177°C |

| Weight | 3 kg |

| Total Length | 1 m |

| Compatible Driver | 3300 NSv Proximitor Sensor |

| Measurement Range | Up to 2 mm (80 mils) dynamic displacement |

| Power Requirement | Supplied by associated Proximitor driver |

Product Applications

-

Measuring radial and axial shaft vibration.

-

Monitoring shaft position in rotating equipment.

-

Detecting dynamic shaft movement in turbines and compressors.

-

Integration with Bently Nevada 3300 NSv systems for compact installation spaces.

-

Industrial applications in power generation, petrochemicals, and oil & gas machinery.

Product Advantages

-

Compact Size – Designed for machinery with tight installation clearances.

-

High Reliability – Provides consistent and accurate readings in harsh environments.

-

Wide Temperature Range – Suitable for high-temperature industrial conditions.

-

Durability – Stainless steel and ceramic tip ensure long-term performance.

-

Seamless Compatibility – Works with Bently Nevada 3300 NSv Proximitor® Sensors.

-

Enhanced Monitoring – Enables early detection of machinery faults, reducing downtime.

FAQ

Q1: What is the primary function of the 330901-00-16-10-11-CN probe?

A1: It measures shaft vibration and position for machinery monitoring and protection.

Q2: Can this probe be used with standard 3300 Proximitor sensors?

A2: No, it is specifically designed for use with the 3300 NSv Proximitor Sensor.

Q3: What is the typical linear measurement range of this probe?

A3: It provides accurate measurements up to 2 mm (80 mils) of dynamic shaft displacement.

Q4: How is the probe signal transmitted to the monitoring system?

A4: Through a coaxial cable connection to the associated Proximitor driver.

Q5: Does the probe require external power?

A5: No, power is supplied from the connected Proximitor Sensor.

Q6: How does the probe maintain accuracy in high temperatures?

A6: It is designed with materials and insulation suitable for operation up to 177°C.

Q7: Is the probe suitable for high-speed turbine applications?

A7: Yes, it is designed for use in turbines, compressors, and other high-speed rotating equipment.

Q8: What is the typical output signal format from the probe system?

A8: The probe and Proximitor together provide a voltage output proportional to shaft displacement.

Q9: Can multiple probes be used in the same monitoring system?

A9: Yes, multiple probes can be configured for complete shaft vibration and position monitoring.

Q10: How is electromagnetic interference minimized?

A10: The coaxial design and shielding of the cable help maintain signal integrity.

Bently Nevada 330901-00-16-10-11-CN 3300 NSv Proximity Probe

Manufacturer:Bently Nevada

Product Number:330901-00-16-10-11-CN

Product Type:3300 NSv Proximity Probe

Origin:USA

Dimensions:1m

Weight :3 kg

Views:11

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330901-00-16-10-11-CN 3300 NSv Proximity Probe is a precision-engineered probe designed for use in the 3300 NSv (Narrow Side View) proximity measurement system. It provides accurate, reliable measurements of shaft vibration and position in machinery where space constraints exist. This probe is tailored for applications with limited installation clearance, offering dependable performance in demanding industrial environments such as turbines, compressors, pumps, and rotating machinery.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | 330901-00-16-10-11-CN |

| Series | 3300 NSv Proximity Probe |

| Connector Type | Standard Bently Nevada coaxial connector |

| Probe Material | Stainless steel body with ceramic tip |

| Operating Temperature | -35°C to +177°C |

| Weight | 3 kg |

| Total Length | 1 m |

| Compatible Driver | 3300 NSv Proximitor Sensor |

| Measurement Range | Up to 2 mm (80 mils) dynamic displacement |

| Power Requirement | Supplied by associated Proximitor driver |

Product Applications

-

Measuring radial and axial shaft vibration.

-

Monitoring shaft position in rotating equipment.

-

Detecting dynamic shaft movement in turbines and compressors.

-

Integration with Bently Nevada 3300 NSv systems for compact installation spaces.

-

Industrial applications in power generation, petrochemicals, and oil & gas machinery.

Product Advantages

-

Compact Size – Designed for machinery with tight installation clearances.

-

High Reliability – Provides consistent and accurate readings in harsh environments.

-

Wide Temperature Range – Suitable for high-temperature industrial conditions.

-

Durability – Stainless steel and ceramic tip ensure long-term performance.

-

Seamless Compatibility – Works with Bently Nevada 3300 NSv Proximitor® Sensors.

-

Enhanced Monitoring – Enables early detection of machinery faults, reducing downtime.

FAQ

Q1: What is the primary function of the 330901-00-16-10-11-CN probe?

A1: It measures shaft vibration and position for machinery monitoring and protection.

Q2: Can this probe be used with standard 3300 Proximitor sensors?

A2: No, it is specifically designed for use with the 3300 NSv Proximitor Sensor.

Q3: What is the typical linear measurement range of this probe?

A3: It provides accurate measurements up to 2 mm (80 mils) of dynamic shaft displacement.

Q4: How is the probe signal transmitted to the monitoring system?

A4: Through a coaxial cable connection to the associated Proximitor driver.

Q5: Does the probe require external power?

A5: No, power is supplied from the connected Proximitor Sensor.

Q6: How does the probe maintain accuracy in high temperatures?

A6: It is designed with materials and insulation suitable for operation up to 177°C.

Q7: Is the probe suitable for high-speed turbine applications?

A7: Yes, it is designed for use in turbines, compressors, and other high-speed rotating equipment.

Q8: What is the typical output signal format from the probe system?

A8: The probe and Proximitor together provide a voltage output proportional to shaft displacement.

Q9: Can multiple probes be used in the same monitoring system?

A9: Yes, multiple probes can be configured for complete shaft vibration and position monitoring.

Q10: How is electromagnetic interference minimized?

A10: The coaxial design and shielding of the cable help maintain signal integrity.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...