Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

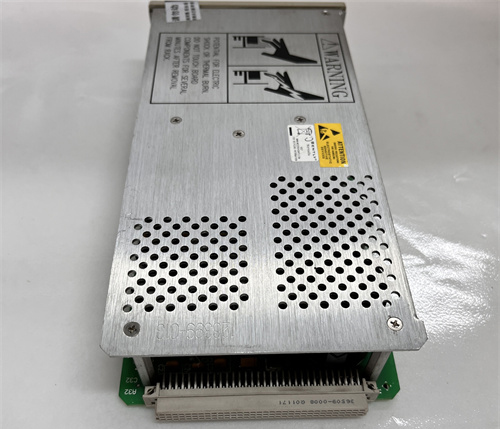

Bently Nevada 3500/34 TMR Relay Module

Manufacturer:Bently Nevada

Product Number:3500/34

Product Type:TMR Relay Module

Origin:USA

Dimensions:120.4 x 24.6 x 241.8 mm

Weight:0.34 kg

Views:114

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/34 TMR Relay Module is a critical component in the 3500 Series machinery protection system, designed to provide reliable relay outputs for alarms, trips, and other control actions. Utilizing a Triple Modular Redundant (TMR) architecture, the 3500/34 ensures enhanced reliability and fault tolerance, making it suitable for high-availability and safety-critical applications.

This module interfaces with the 3500 Series monitoring system, converting processed vibration and process signals into discrete relay outputs for external control systems. Its design emphasizes rapid response, precise signal handling, and system integrity, providing a dependable link between machinery condition monitoring and plant control actions.

The 3500/34 is widely employed in industries where continuous monitoring and machine protection are essential, including power generation, petrochemical, oil & gas, and large industrial rotating equipment applications.

Product Parameters

| Parameter | Specification |

|---|---|

| Manufacturer | Bently Nevada |

| Model Number | 3500/34 |

| Product Type | TMR Relay Module |

| Architecture | Triple Modular Redundant (TMR) |

| Input Signals | Processed 3500 Series monitoring signals |

| Output Signals | Relay contacts (Form A, Form C, depending on configuration) |

| Number of Relays | 8–16 per module (depending on configuration) |

| Contact Rating | 2 A @ 30 VDC / 0.5 A @ 125 VDC |

| Response Time | <50 ms typical |

| LED Indicators | Relay status, fault indication |

| Mounting Type | Rack-mounted in 3500 Series chassis |

| Power Supply | 24 VDC (via 3500 chassis backplane) |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5%–95% non-condensing |

| Cooling Method | Passive cooling via chassis airflow |

| Dimensions (W x H x D) | 120.4 x 24.6 x 241.8 mm |

| Weight | 0.34 kg |

Product Applications

The 3500/34 TMR Relay Module is used across critical machinery monitoring and protection systems:

-

Rotating Equipment Protection – Interfaces with vibration and process sensors to trigger alarms or trips.

-

Power Generation – Provides relay outputs for turbine, generator, and auxiliary system protection.

-

Oil & Gas Facilities – Triggers safety interlocks, shutdowns, and alarm circuits for critical pumps, compressors, and rotating machinery.

-

Petrochemical Plants – Facilitates automatic control actions based on machinery condition monitoring.

-

Industrial Manufacturing – Ensures reliable relay outputs for large motor or pump protection systems.

-

Process Control Integration – Connects condition monitoring to SCADA, DCS, and PLC systems.

Product Advantages

-

High Reliability – Triple Modular Redundant (TMR) design ensures continued operation even during module faults.

-

Fast Response – Relay outputs respond quickly to monitored events, protecting equipment from damage.

-

Flexible Integration – Compatible with the full range of Bently Nevada 3500 Series monitoring modules.

-

Diagnostic Visibility – LED indicators allow operators to quickly identify active relays and module status.

-

Low Maintenance – Passive cooling and robust construction reduce service requirements.

-

Scalable Design – Supports multiple relay configurations to meet diverse system needs.

-

Industrial-Grade Construction – Designed for vibration, EMI, and environmental robustness.

FAQ

1. How many relay outputs does the 3500/34 module provide?

It provides 8–16 relay outputs per module, depending on the configuration and chassis.

2. Can the 3500/34 module operate in TMR mode with other 3500 modules?

Yes, it operates in Triple Modular Redundant mode alongside other 3500 Series TMR modules.

3. What is the typical relay response time?

The relay response time is typically less than 50 milliseconds.

4. How are relay outputs rated?

Relay contacts are rated at 2 A @ 30 VDC or 0.5 A @ 125 VDC, suitable for signaling and control applications.

5. Are there diagnostic indicators on the module?

Yes, LEDs indicate relay status, faults, and TMR module health.

6. Can this module interface with a PLC or DCS?

Yes, the relay outputs can be wired to PLCs, DCS, SCADA systems, or external alarms.

7. How is the module powered?

It receives 24 VDC from the 3500 Series chassis backplane.

8. Is the module hot-swappable?

No, the module should be powered down before installation or removal to ensure safety and data integrity.

9. What type of mounting does the module require?

It is rack-mounted within the 3500 Series chassis.

10. How does the TMR architecture improve reliability?

TMR duplicates core processing across three channels, allowing the module to continue operating even if one channel fails, reducing the risk of false trips.

Bently Nevada 3500/34 TMR Relay Module

Manufacturer:Bently Nevada

Product Number:3500/34

Product Type:TMR Relay Module

Origin:USA

Dimensions:120.4 x 24.6 x 241.8 mm

Weight:0.34 kg

Views:114

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/34 TMR Relay Module is a critical component in the 3500 Series machinery protection system, designed to provide reliable relay outputs for alarms, trips, and other control actions. Utilizing a Triple Modular Redundant (TMR) architecture, the 3500/34 ensures enhanced reliability and fault tolerance, making it suitable for high-availability and safety-critical applications.

This module interfaces with the 3500 Series monitoring system, converting processed vibration and process signals into discrete relay outputs for external control systems. Its design emphasizes rapid response, precise signal handling, and system integrity, providing a dependable link between machinery condition monitoring and plant control actions.

The 3500/34 is widely employed in industries where continuous monitoring and machine protection are essential, including power generation, petrochemical, oil & gas, and large industrial rotating equipment applications.

Product Parameters

| Parameter | Specification |

|---|---|

| Manufacturer | Bently Nevada |

| Model Number | 3500/34 |

| Product Type | TMR Relay Module |

| Architecture | Triple Modular Redundant (TMR) |

| Input Signals | Processed 3500 Series monitoring signals |

| Output Signals | Relay contacts (Form A, Form C, depending on configuration) |

| Number of Relays | 8–16 per module (depending on configuration) |

| Contact Rating | 2 A @ 30 VDC / 0.5 A @ 125 VDC |

| Response Time | <50 ms typical |

| LED Indicators | Relay status, fault indication |

| Mounting Type | Rack-mounted in 3500 Series chassis |

| Power Supply | 24 VDC (via 3500 chassis backplane) |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5%–95% non-condensing |

| Cooling Method | Passive cooling via chassis airflow |

| Dimensions (W x H x D) | 120.4 x 24.6 x 241.8 mm |

| Weight | 0.34 kg |

Product Applications

The 3500/34 TMR Relay Module is used across critical machinery monitoring and protection systems:

-

Rotating Equipment Protection – Interfaces with vibration and process sensors to trigger alarms or trips.

-

Power Generation – Provides relay outputs for turbine, generator, and auxiliary system protection.

-

Oil & Gas Facilities – Triggers safety interlocks, shutdowns, and alarm circuits for critical pumps, compressors, and rotating machinery.

-

Petrochemical Plants – Facilitates automatic control actions based on machinery condition monitoring.

-

Industrial Manufacturing – Ensures reliable relay outputs for large motor or pump protection systems.

-

Process Control Integration – Connects condition monitoring to SCADA, DCS, and PLC systems.

Product Advantages

-

High Reliability – Triple Modular Redundant (TMR) design ensures continued operation even during module faults.

-

Fast Response – Relay outputs respond quickly to monitored events, protecting equipment from damage.

-

Flexible Integration – Compatible with the full range of Bently Nevada 3500 Series monitoring modules.

-

Diagnostic Visibility – LED indicators allow operators to quickly identify active relays and module status.

-

Low Maintenance – Passive cooling and robust construction reduce service requirements.

-

Scalable Design – Supports multiple relay configurations to meet diverse system needs.

-

Industrial-Grade Construction – Designed for vibration, EMI, and environmental robustness.

FAQ

1. How many relay outputs does the 3500/34 module provide?

It provides 8–16 relay outputs per module, depending on the configuration and chassis.

2. Can the 3500/34 module operate in TMR mode with other 3500 modules?

Yes, it operates in Triple Modular Redundant mode alongside other 3500 Series TMR modules.

3. What is the typical relay response time?

The relay response time is typically less than 50 milliseconds.

4. How are relay outputs rated?

Relay contacts are rated at 2 A @ 30 VDC or 0.5 A @ 125 VDC, suitable for signaling and control applications.

5. Are there diagnostic indicators on the module?

Yes, LEDs indicate relay status, faults, and TMR module health.

6. Can this module interface with a PLC or DCS?

Yes, the relay outputs can be wired to PLCs, DCS, SCADA systems, or external alarms.

7. How is the module powered?

It receives 24 VDC from the 3500 Series chassis backplane.

8. Is the module hot-swappable?

No, the module should be powered down before installation or removal to ensure safety and data integrity.

9. What type of mounting does the module require?

It is rack-mounted within the 3500 Series chassis.

10. How does the TMR architecture improve reliability?

TMR duplicates core processing across three channels, allowing the module to continue operating even if one channel fails, reducing the risk of false trips.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...