Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

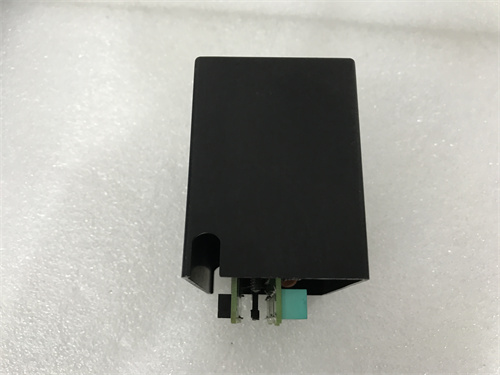

General Electric IC693MDL753 Positive/Negative Logic Output Module

Manufacturer:GE

Product Number:IC693MDL753

Product Type:Positive/Negative Logic Output Module

Origin:USA

Dimensions:150 × 100 × 70 mm

Weight:0.231kg

Views:63

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

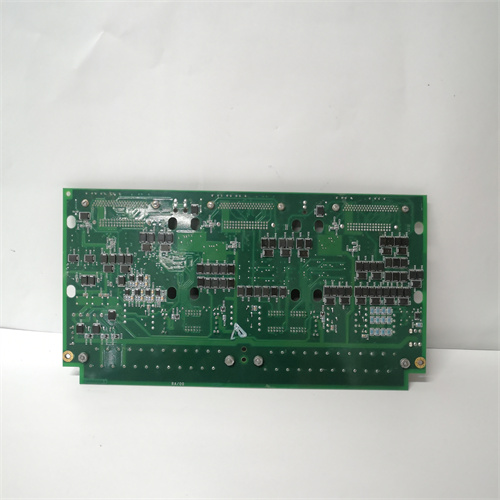

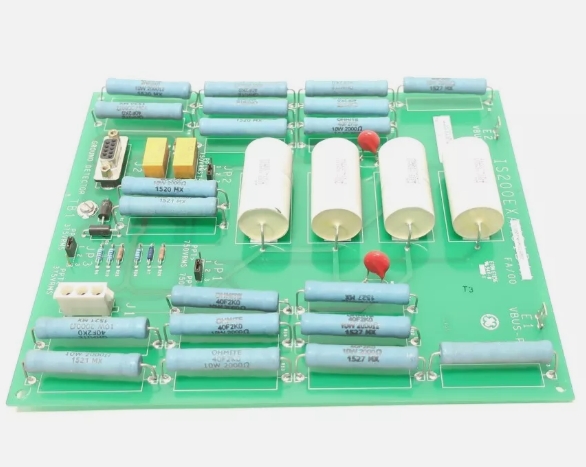

The GE IC693MDL753 is a versatile positive/negative logic output module designed for the Series 90-30 programmable logic controller (PLC) family from General Electric. This module provides eight channels of configurable output, allowing each channel to be set for either sourcing (positive logic) or sinking (negative logic) operation. Designed for industrial environments, the IC693MDL753 delivers reliable digital output switching to control a wide range of loads such as relays, solenoids, indicators, and small actuators. Its compact size, robust protection features, and flexible configuration options make it an essential component in mid-to-large-scale automation and control systems.

Engineered with high-performance solid-state switching elements, the MDL753 ensures minimal voltage drop, fast response times, and excellent noise immunity. Each output channel can be independently configured and monitored, providing diagnostic feedback for troubleshooting and maintenance. The module’s ability to handle mixed logic polarities simplifies wiring and reduces the need for separate modules when both sinking and sourcing outputs are required on the same I/O card.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Positive/Negative Logic Output Module |

| Model Number | IC693MDL753 |

| Manufacturer | GE Fanuc Automation |

| I/O Type | Discrete Output, configurable as sourcing (PNP) or sinking (NPN) |

| Number of Channels | 8 channels |

| Output Voltage Range | 5–28 VDC |

| Output Current | 0.5 A per channel (up to module total of 4 A) |

| Logic Polarity | Positive (sourcing) or Negative (sinking) configurable per channel |

| Isolation | Optical isolation from backplane and between channels |

| Switching Elements | Solid-state transistors |

| Response Time | <5 microseconds |

| Fault Protection | Overcurrent and short-circuit protection with diagnostic feedback |

| Status Indicators | Individual channel LEDs for ON state and module status LEDs |

| Configuration Interface | DIP switches and software configuration via programming software |

| Operating Temperature | 0 to 60 °C |

| Storage Temperature | -40 to 85 °C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Shock Resistance | IEC 60068-2-27 compliant |

| Vibration Resistance | IEC 60068-2-6 compliant |

| Power Supply | 5 VDC from Series 90-30 backplane |

| Mounting | DIN rail or rack-mount |

| Dimensions | 150 × 100 × 70 mm |

| Weight | 0.231 kg |

Applications

-

Discrete Output Control in Industrial Automation

Utilized for controlling relays, solenoids, and pilot lights in manufacturing assembly lines, packaging machines, and material handling systems. The ability to switch both sourcing and sinking loads on the same module simplifies rack design and reduces component count.

-

Motor Starter and Contactor Activation

Configured to drive contactor coils directly, the MDL753 can handle inrush currents typical of small motor loads. Its solid-state switching provides fast, silent operation and reduces mechanical wear compared to relay outputs.

-

Distributed Control System (DCS) Integration

Deployed as part of Series 90-30 systems in chemical, petrochemical, and oil & gas facilities, where it interfaces with field-mounted devices to execute control logic and provide interlocking functions in process control loops.

-

Machine Safety Interlocks

Employed to energize safety relays and interlock devices in packaging, printing, and machine tool applications. The module’s diagnostic capabilities ensure that any fault (e.g., short circuit) is reported promptly to the PLC CPU for safe shutdown or alarm generation.

-

HMI/SCADA Feedback Outputs

Used to drive indicator lamps or alarms within operator workstations and remote terminal units (RTUs). Its fast response time (<5 µs) ensures near-instantaneous visual or audible feedback when a controlled condition changes.

-

Rail and Transportation Control

Incorporated into rail signaling and station automation for switching trackside signals and station equipment. The module’s wide temperature rating (0 to 60 °C) and robust design suit semi-outdoor control cabinets.

-

Automation of HVAC Systems

Applied to control dampers, valves, and pumps in large commercial or industrial HVAC systems, providing precise on/off control with fault monitoring for preventive maintenance.

Advantages

-

Flexible Logic Configuration

Each channel can be independently set to source or sink current, allowing mixed-polarity output configurations without requiring separate modules. This flexibility reduces wiring complexity and inventory costs.

-

High Channel Density

Offers eight outputs in a single, compact package occupying only one slot in the 90-30 rack. This high density lowers system complexity and conserves valuable panel space.

-

Solid-State Reliability

Uses transistor-based switching with no mechanical moving parts, resulting in superior switching speed (<5 µs), silent operation, and extended service life under high cycling conditions.

-

Integrated Circuit Protection

Built-in overcurrent and short-circuit protection on each channel prevents damage to wiring and connected devices. Diagnostics report channel faults back to the CPU, enabling rapid fault isolation.

-

Enhanced Diagnostic Feedback

Individual LEDs per channel display ON/OFF status, and module status LEDs indicate power, fault, and communication status. This visual feedback simplifies troubleshooting and reduces mean time to repair (MTTR).

-

Seamless Backplane Integration

Draws power directly from the Series 90-30 backplane (5 VDC), eliminating the need for separate wiring. Module insertion and removal do not disturb adjacent modules, thanks to hot-swap capability (with backplane power maintained).

-

Industrial-Grade Design

Compliant with IEC 60068 shock and vibration standards, it withstands harsh manufacturing environments. Operating temperature range (0 to 60 °C) covers typical industrial spaces without requiring external cooling.

-

Simplified Configuration

DIP switches allow manual selection of polarity and address settings if programming software is unavailable. When used with GE’s programming suite, channel configuration is managed centrally alongside logic development.

Frequently Asked Questions (FAQ)

Q1: How is the logic polarity configured on the IC693MDL753?

A1: Each of the eight channels is configured via DIP switches for either sourcing (positive logic) or sinking (negative logic). These DIP switch settings can also be overridden through programming parameters using GE’s software tools.

Q2: What type of loads can the MDL753 drive directly?

A2: The module can drive a variety of DC loads up to 0.5 A per channel, including pilot lights, relays, solenoid coils (of low inrush rating), and small DC motors when used with external driver circuits.

Q3: How does the module report a short-circuit or overload fault?

A3: When a short circuit or overcurrent condition occurs, the internal protection circuitry opens that channel. The corresponding channel LED flashes to indicate a fault. The PLC CPU receives a diagnostic flag signaling the fault for further action.

Q4: Can the MDL753 be hot-swapped in the Series 90-30 rack?

A4: Yes. As long as the backplane remains powered, this module may be inserted or removed without shutting down the entire rack. Other modules continue to operate normally.

Q5: What is the maximum total current draw of all eight channels?

A5: While each channel can supply up to 0.5 A, the sum of currents on all channels must not exceed 4 A. Exceeding 4 A total may trigger module overheating or fault protection.

Q6: How do I integrate the MDL753 into an existing PLC program?

A6: In GE’s programming software (e.g., Proficy Machine Edition), add the MDL753 to the I/O configuration under the appropriate slot number. Configure each channel’s polarity, address, and override conditions as required by the control logic.

Q7: What is the significance of optical isolation in this module?

A7: Optical isolation separates the module’s input/output circuits from the backplane and between channels, protecting the PLC CPU from voltage transients and reducing ground-loop interference, thereby improving system reliability.

Q8: Are there any maintenance procedures recommended for this module?

A8: Inspect LED indicators periodically for fault conditions. Verify wiring terminations for corrosion or loosening. Clean dust buildup inside control cabinets to ensure adequate heat dissipation. Replace the module if repeated fault events occur, indicating potential internal component degradation.

Q9: In which environments is the MDL753 most suitable?

A9: It is ideal for industrial settings such as discrete manufacturing, packaging, material handling, HVAC control, and infrastructure automation where reliable digital switching and diagnostic capability are essential.

Q10: What should I check if a channel fails to switch on as expected?

A10: First, verify DIP switch polarity settings correspond to the desired sourcing/sinking mode. Check wiring continuity from module output to load. Confirm no overload or short-circuit conditions exist. Finally, observe the channel LED: a steady ON state indicates normal output; a fault-flashing LED indicates protection has engaged.

General Electric IC693MDL753 Positive/Negative Logic Output Module

Manufacturer:GE

Product Number:IC693MDL753

Product Type:Positive/Negative Logic Output Module

Origin:USA

Dimensions:150 × 100 × 70 mm

Weight:0.231kg

Views:63

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IC693MDL753 is a versatile positive/negative logic output module designed for the Series 90-30 programmable logic controller (PLC) family from General Electric. This module provides eight channels of configurable output, allowing each channel to be set for either sourcing (positive logic) or sinking (negative logic) operation. Designed for industrial environments, the IC693MDL753 delivers reliable digital output switching to control a wide range of loads such as relays, solenoids, indicators, and small actuators. Its compact size, robust protection features, and flexible configuration options make it an essential component in mid-to-large-scale automation and control systems.

Engineered with high-performance solid-state switching elements, the MDL753 ensures minimal voltage drop, fast response times, and excellent noise immunity. Each output channel can be independently configured and monitored, providing diagnostic feedback for troubleshooting and maintenance. The module’s ability to handle mixed logic polarities simplifies wiring and reduces the need for separate modules when both sinking and sourcing outputs are required on the same I/O card.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Positive/Negative Logic Output Module |

| Model Number | IC693MDL753 |

| Manufacturer | GE Fanuc Automation |

| I/O Type | Discrete Output, configurable as sourcing (PNP) or sinking (NPN) |

| Number of Channels | 8 channels |

| Output Voltage Range | 5–28 VDC |

| Output Current | 0.5 A per channel (up to module total of 4 A) |

| Logic Polarity | Positive (sourcing) or Negative (sinking) configurable per channel |

| Isolation | Optical isolation from backplane and between channels |

| Switching Elements | Solid-state transistors |

| Response Time | <5 microseconds |

| Fault Protection | Overcurrent and short-circuit protection with diagnostic feedback |

| Status Indicators | Individual channel LEDs for ON state and module status LEDs |

| Configuration Interface | DIP switches and software configuration via programming software |

| Operating Temperature | 0 to 60 °C |

| Storage Temperature | -40 to 85 °C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Shock Resistance | IEC 60068-2-27 compliant |

| Vibration Resistance | IEC 60068-2-6 compliant |

| Power Supply | 5 VDC from Series 90-30 backplane |

| Mounting | DIN rail or rack-mount |

| Dimensions | 150 × 100 × 70 mm |

| Weight | 0.231 kg |

Applications

-

Discrete Output Control in Industrial Automation

Utilized for controlling relays, solenoids, and pilot lights in manufacturing assembly lines, packaging machines, and material handling systems. The ability to switch both sourcing and sinking loads on the same module simplifies rack design and reduces component count.

-

Motor Starter and Contactor Activation

Configured to drive contactor coils directly, the MDL753 can handle inrush currents typical of small motor loads. Its solid-state switching provides fast, silent operation and reduces mechanical wear compared to relay outputs.

-

Distributed Control System (DCS) Integration

Deployed as part of Series 90-30 systems in chemical, petrochemical, and oil & gas facilities, where it interfaces with field-mounted devices to execute control logic and provide interlocking functions in process control loops.

-

Machine Safety Interlocks

Employed to energize safety relays and interlock devices in packaging, printing, and machine tool applications. The module’s diagnostic capabilities ensure that any fault (e.g., short circuit) is reported promptly to the PLC CPU for safe shutdown or alarm generation.

-

HMI/SCADA Feedback Outputs

Used to drive indicator lamps or alarms within operator workstations and remote terminal units (RTUs). Its fast response time (<5 µs) ensures near-instantaneous visual or audible feedback when a controlled condition changes.

-

Rail and Transportation Control

Incorporated into rail signaling and station automation for switching trackside signals and station equipment. The module’s wide temperature rating (0 to 60 °C) and robust design suit semi-outdoor control cabinets.

-

Automation of HVAC Systems

Applied to control dampers, valves, and pumps in large commercial or industrial HVAC systems, providing precise on/off control with fault monitoring for preventive maintenance.

Advantages

-

Flexible Logic Configuration

Each channel can be independently set to source or sink current, allowing mixed-polarity output configurations without requiring separate modules. This flexibility reduces wiring complexity and inventory costs.

-

High Channel Density

Offers eight outputs in a single, compact package occupying only one slot in the 90-30 rack. This high density lowers system complexity and conserves valuable panel space.

-

Solid-State Reliability

Uses transistor-based switching with no mechanical moving parts, resulting in superior switching speed (<5 µs), silent operation, and extended service life under high cycling conditions.

-

Integrated Circuit Protection

Built-in overcurrent and short-circuit protection on each channel prevents damage to wiring and connected devices. Diagnostics report channel faults back to the CPU, enabling rapid fault isolation.

-

Enhanced Diagnostic Feedback

Individual LEDs per channel display ON/OFF status, and module status LEDs indicate power, fault, and communication status. This visual feedback simplifies troubleshooting and reduces mean time to repair (MTTR).

-

Seamless Backplane Integration

Draws power directly from the Series 90-30 backplane (5 VDC), eliminating the need for separate wiring. Module insertion and removal do not disturb adjacent modules, thanks to hot-swap capability (with backplane power maintained).

-

Industrial-Grade Design

Compliant with IEC 60068 shock and vibration standards, it withstands harsh manufacturing environments. Operating temperature range (0 to 60 °C) covers typical industrial spaces without requiring external cooling.

-

Simplified Configuration

DIP switches allow manual selection of polarity and address settings if programming software is unavailable. When used with GE’s programming suite, channel configuration is managed centrally alongside logic development.

Frequently Asked Questions (FAQ)

Q1: How is the logic polarity configured on the IC693MDL753?

A1: Each of the eight channels is configured via DIP switches for either sourcing (positive logic) or sinking (negative logic). These DIP switch settings can also be overridden through programming parameters using GE’s software tools.

Q2: What type of loads can the MDL753 drive directly?

A2: The module can drive a variety of DC loads up to 0.5 A per channel, including pilot lights, relays, solenoid coils (of low inrush rating), and small DC motors when used with external driver circuits.

Q3: How does the module report a short-circuit or overload fault?

A3: When a short circuit or overcurrent condition occurs, the internal protection circuitry opens that channel. The corresponding channel LED flashes to indicate a fault. The PLC CPU receives a diagnostic flag signaling the fault for further action.

Q4: Can the MDL753 be hot-swapped in the Series 90-30 rack?

A4: Yes. As long as the backplane remains powered, this module may be inserted or removed without shutting down the entire rack. Other modules continue to operate normally.

Q5: What is the maximum total current draw of all eight channels?

A5: While each channel can supply up to 0.5 A, the sum of currents on all channels must not exceed 4 A. Exceeding 4 A total may trigger module overheating or fault protection.

Q6: How do I integrate the MDL753 into an existing PLC program?

A6: In GE’s programming software (e.g., Proficy Machine Edition), add the MDL753 to the I/O configuration under the appropriate slot number. Configure each channel’s polarity, address, and override conditions as required by the control logic.

Q7: What is the significance of optical isolation in this module?

A7: Optical isolation separates the module’s input/output circuits from the backplane and between channels, protecting the PLC CPU from voltage transients and reducing ground-loop interference, thereby improving system reliability.

Q8: Are there any maintenance procedures recommended for this module?

A8: Inspect LED indicators periodically for fault conditions. Verify wiring terminations for corrosion or loosening. Clean dust buildup inside control cabinets to ensure adequate heat dissipation. Replace the module if repeated fault events occur, indicating potential internal component degradation.

Q9: In which environments is the MDL753 most suitable?

A9: It is ideal for industrial settings such as discrete manufacturing, packaging, material handling, HVAC control, and infrastructure automation where reliable digital switching and diagnostic capability are essential.

Q10: What should I check if a channel fails to switch on as expected?

A10: First, verify DIP switch polarity settings correspond to the desired sourcing/sinking mode. Check wiring continuity from module output to load. Confirm no overload or short-circuit conditions exist. Finally, observe the channel LED: a steady ON state indicates normal output; a fault-flashing LED indicates protection has engaged.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...