Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

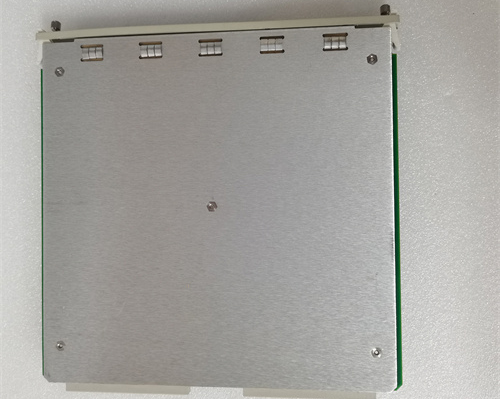

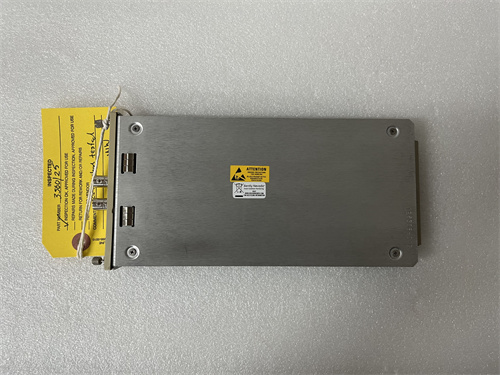

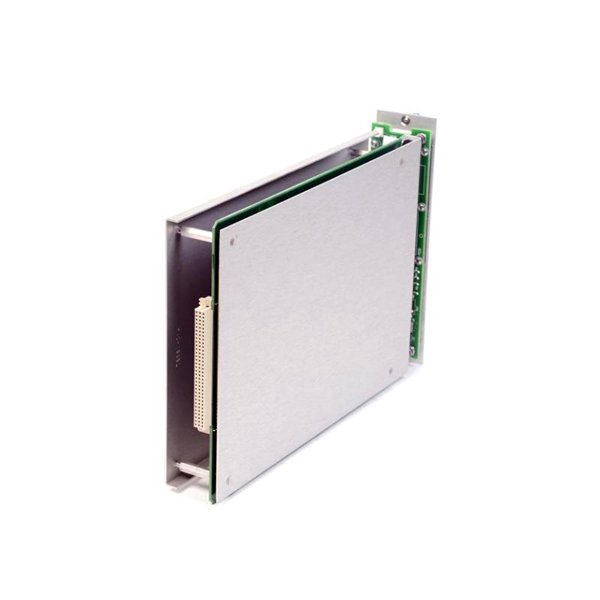

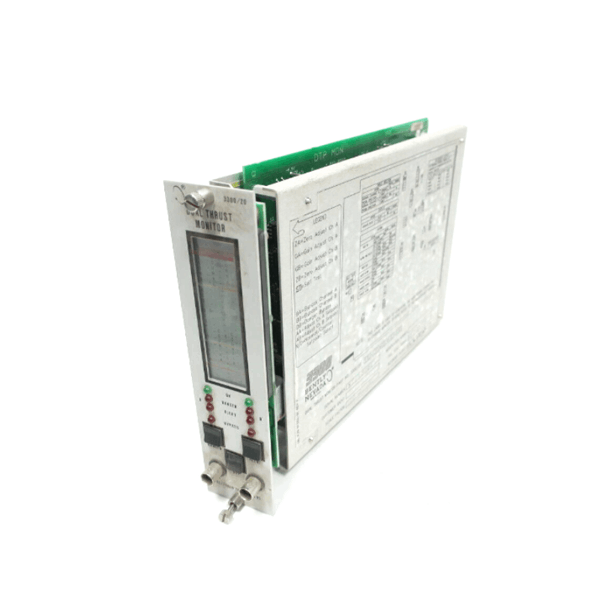

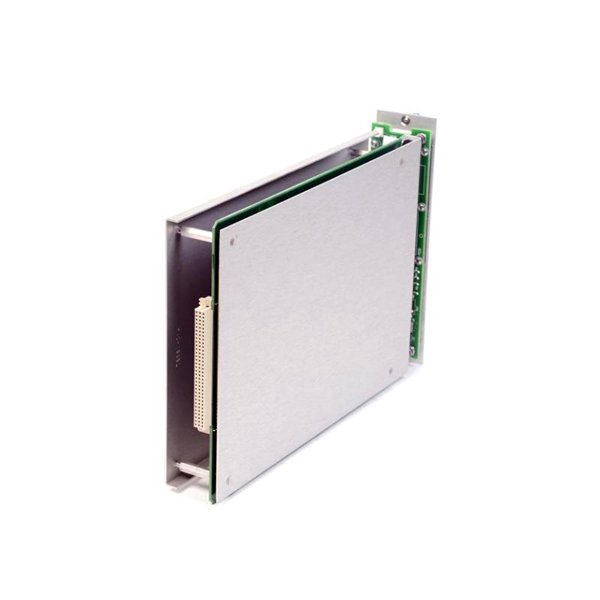

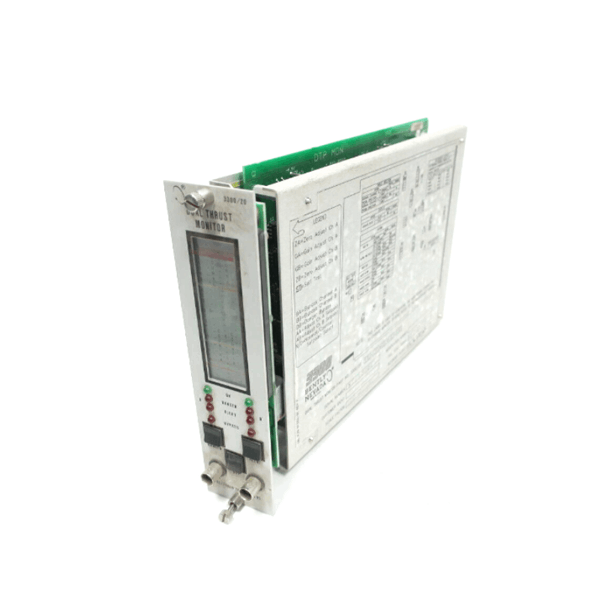

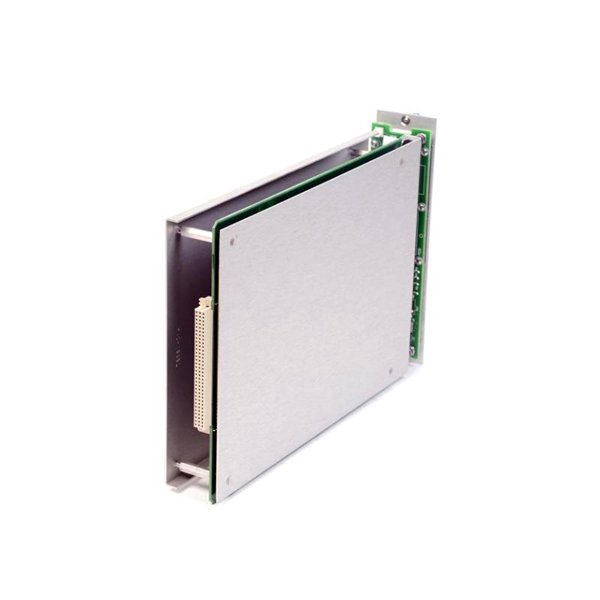

Bently Nevada 3300/20-12-01-00-00-00 Dual Thrust Position Monitor

Manufacturer:Bently Nevada

Product Number:3300/20-12-01-00-00-00

Product Type:Dual Thrust Position Monitor

Origin:USA

Vertical Dimension:83 mm

Weight:1 kg

Views:74

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3300/20-12-01-00-00-00 Dual Thrust Position Monitor is a specialized device designed to provide continuous monitoring of shaft axial position in rotating machinery. By measuring two independent channels of shaft axial position relative to the machine’s axial clearances, it offers early detection of thrust bearing wear or failure, thereby preventing unexpected machinery downtime and potential damage.

Product Specifications

| Specification | Details |

|---|---|

| Full-Scale Range Option | 1.0-0-1.0 mm |

| Transducer Input Option | Compatible with 3300 or 7200 Proximitor® systems, 200 mV/mil (suitable for ranges 01, 02, 03, 11, and 12) |

| Alarm Relay Option | Epoxy-Sealed |

| Agency Approval Option | CSA/NRTL/C |

| Display Resolution | Within ±1.6% of monitor full-scale |

| Vertical Dimension | 83 mm |

| Weight | 1 kg |

Applications

This monitor is essential in industries where rotating machinery is critical, including:

- Power Generation: Monitoring turbines to ensure efficient operation and prevent failures.

- Oil and Gas: Overseeing compressors and pumps to maintain continuous operations.

- Manufacturing: Ensuring the reliability of machinery such as fans and blowers.

Advantages

- Early Warning System: Provides timely alerts of thrust bearing issues, allowing for proactive maintenance.

- Dual-Channel Monitoring: Offers redundancy and increased reliability by monitoring two channels simultaneously.

- Compatibility: Works seamlessly with 3300 or 7200 Proximitor® systems, enhancing versatility.

- High Accuracy: Ensures precise measurements with a display resolution within ±1.6% of full-scale.

FAQs

-

What is the primary function of the 3300/20-12-01-00-00-00 Dual Thrust Position Monitor?

- It continuously measures and monitors two independent channels of shaft axial position relative to the machine’s axial clearances, providing early warning of thrust bearing wear or failure.

-

Which transducer systems are compatible with this monitor?

- It is compatible with 3300 or 7200 Proximitor® systems, specifically those with a sensitivity of 200 mV/mil.

-

What industries commonly use this monitor?

- Industries such as power generation, oil and gas, and manufacturing commonly utilize this monitor for machinery protection.

-

How does the dual-channel feature benefit machinery monitoring?

- The dual-channel feature allows for redundancy and increased reliability by monitoring two independent channels simultaneously.

-

What is the significance of the CSA/NRTL/C agency approval?

- This approval indicates compliance with North American safety standards, ensuring the monitor meets specific safety and performance criteria.

-

Can this monitor detect early signs of thrust bearing failure?

- Yes, it provides early detection of potential machinery faults, allowing for proactive maintenance and preventing catastrophic failures.

-

What are the dimensions and weight of the monitor?

- The monitor measures vertical dimension 83 mm and weighs 1 kg.

-

Is the alarm relay option customizable?

- Yes, this model comes with an epoxy-sealed alarm relay option, but other configurations may be available depending on specific requirements.

-

What is the display resolution accuracy?

- The display resolution is within ±1.6% of the monitor’s full-scale range, ensuring precise measurements.

-

Does the monitor require a safety barrier?

- This particular model does not include a safety barrier option, but configurations with internal safety barriers are available.

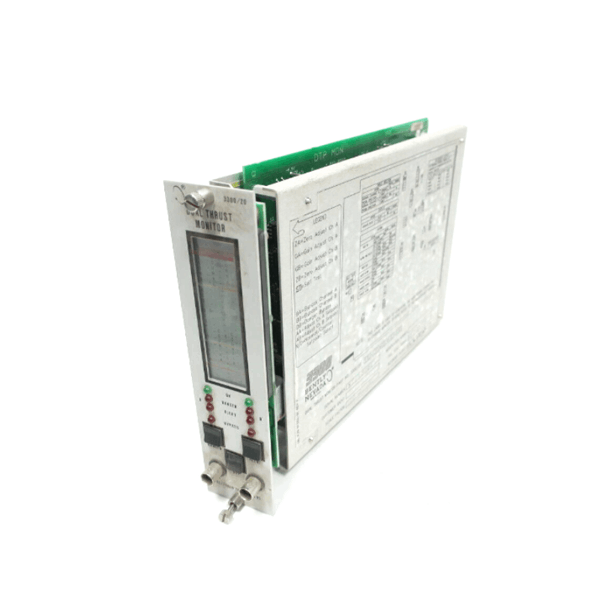

Bently Nevada 3300/20-12-01-00-00-00 Dual Thrust Position Monitor

Manufacturer:Bently Nevada

Product Number:3300/20-12-01-00-00-00

Product Type:Dual Thrust Position Monitor

Origin:USA

Vertical Dimension:83 mm

Weight:1 kg

Views:74

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3300/20-12-01-00-00-00 Dual Thrust Position Monitor is a specialized device designed to provide continuous monitoring of shaft axial position in rotating machinery. By measuring two independent channels of shaft axial position relative to the machine’s axial clearances, it offers early detection of thrust bearing wear or failure, thereby preventing unexpected machinery downtime and potential damage.

Product Specifications

| Specification | Details |

|---|---|

| Full-Scale Range Option | 1.0-0-1.0 mm |

| Transducer Input Option | Compatible with 3300 or 7200 Proximitor® systems, 200 mV/mil (suitable for ranges 01, 02, 03, 11, and 12) |

| Alarm Relay Option | Epoxy-Sealed |

| Agency Approval Option | CSA/NRTL/C |

| Display Resolution | Within ±1.6% of monitor full-scale |

| Vertical Dimension | 83 mm |

| Weight | 1 kg |

Applications

This monitor is essential in industries where rotating machinery is critical, including:

- Power Generation: Monitoring turbines to ensure efficient operation and prevent failures.

- Oil and Gas: Overseeing compressors and pumps to maintain continuous operations.

- Manufacturing: Ensuring the reliability of machinery such as fans and blowers.

Advantages

- Early Warning System: Provides timely alerts of thrust bearing issues, allowing for proactive maintenance.

- Dual-Channel Monitoring: Offers redundancy and increased reliability by monitoring two channels simultaneously.

- Compatibility: Works seamlessly with 3300 or 7200 Proximitor® systems, enhancing versatility.

- High Accuracy: Ensures precise measurements with a display resolution within ±1.6% of full-scale.

FAQs

-

What is the primary function of the 3300/20-12-01-00-00-00 Dual Thrust Position Monitor?

- It continuously measures and monitors two independent channels of shaft axial position relative to the machine’s axial clearances, providing early warning of thrust bearing wear or failure.

-

Which transducer systems are compatible with this monitor?

- It is compatible with 3300 or 7200 Proximitor® systems, specifically those with a sensitivity of 200 mV/mil.

-

What industries commonly use this monitor?

- Industries such as power generation, oil and gas, and manufacturing commonly utilize this monitor for machinery protection.

-

How does the dual-channel feature benefit machinery monitoring?

- The dual-channel feature allows for redundancy and increased reliability by monitoring two independent channels simultaneously.

-

What is the significance of the CSA/NRTL/C agency approval?

- This approval indicates compliance with North American safety standards, ensuring the monitor meets specific safety and performance criteria.

-

Can this monitor detect early signs of thrust bearing failure?

- Yes, it provides early detection of potential machinery faults, allowing for proactive maintenance and preventing catastrophic failures.

-

What are the dimensions and weight of the monitor?

- The monitor measures vertical dimension 83 mm and weighs 1 kg.

-

Is the alarm relay option customizable?

- Yes, this model comes with an epoxy-sealed alarm relay option, but other configurations may be available depending on specific requirements.

-

What is the display resolution accuracy?

- The display resolution is within ±1.6% of the monitor’s full-scale range, ensuring precise measurements.

-

Does the monitor require a safety barrier?

- This particular model does not include a safety barrier option, but configurations with internal safety barriers are available.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...