Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

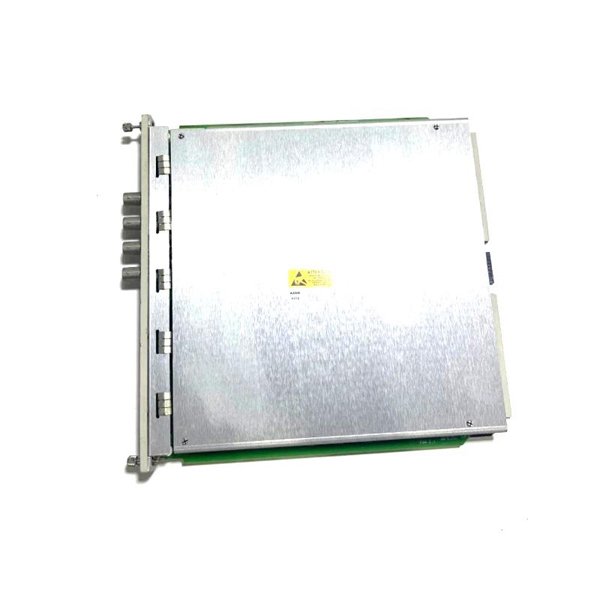

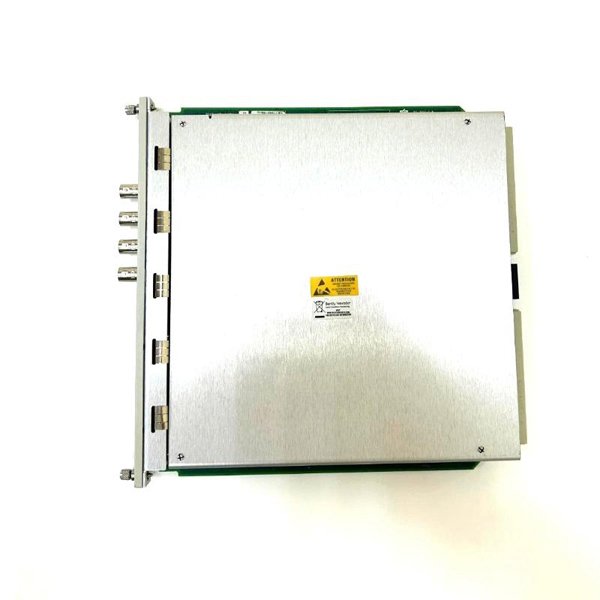

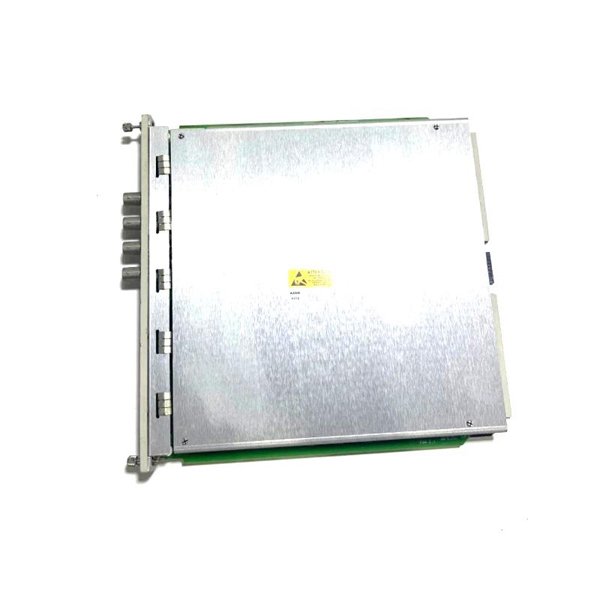

Bently Nevada 3500/42-04-CN Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42-04-CN

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:38

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42-04-CN Proximitor Seismic Monitor is an advanced vibration and position monitoring module designed for critical rotating machinery protection. It delivers real-time measurement and alarming functions for proximity probes and seismic transducers, ensuring machine health and operational safety in demanding industrial environments.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 3500/42-04-CN |

| Measurement Types | Radial Vibration, Thrust Position, Eccentricity, Shaft Position |

| Input Channels | 4 |

| Signal Type | Proximitor / Seismic |

| Accuracy | ±0.25% of full scale |

| Alarm Setpoints | 2 per channel (Alert, Danger) |

| Outputs | 4–20 mA proportional, relay contacts |

| Communication | Rack Interface to 3500 System |

| Power Consumption | ≤ 10 W |

| Operating Temperature | –30°C to +65°C |

| Dimensions (H × W × D) | 241.3 × 24.4 × 241.8 mm |

| Weight | 0.91 kg |

Applications

-

Continuous monitoring of steam turbines, compressors, pumps, and motors.

-

Shaft vibration and displacement tracking in high-value machinery.

-

Early fault detection in bearing systems and rotor dynamics.

-

Integration with plant-wide condition monitoring systems.

-

Compliance with API 670 for machinery protection.

Product Advantages

-

High Reliability: Industrial-grade design for 24/7 operation.

-

Flexible Configuration: Multiple measurement modes per channel.

-

Fast Response: Real-time alarming with minimal latency.

-

Integration Ready: Seamless connectivity with the 3500 Series framework.

-

Compliance: Meets stringent industrial monitoring standards.

FAQ

-

What sensors are compatible with the 3500/42-04-CN?

Proximity probes, velocity transducers, and accelerometers designed for Bently Nevada systems.

-

Can this module be used for thrust position monitoring?

Yes, it supports thrust position measurement with appropriate transducers.

-

Does it support redundant monitoring?

Yes, when configured in a redundant rack system.

-

How many alarm levels are available?

Two per channel: Alert and Danger.

-

Is it compliant with API 670?

Yes, it fully meets API 670 requirements.

-

Can the output be integrated into a DCS?

Yes, via 4–20 mA and relay outputs.

-

What is the accuracy of measurements?

±0.25% of full-scale output.

-

Does it require calibration?

Calibration is recommended during installation and periodic maintenance.

-

Can it operate in extreme temperatures?

Yes, from –30°C to +65°C.

-

Is firmware upgradeable?

Yes, through the 3500 rack system interface.

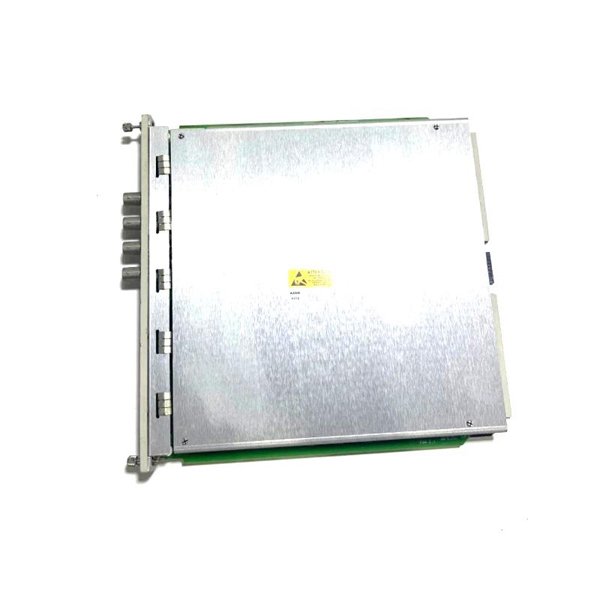

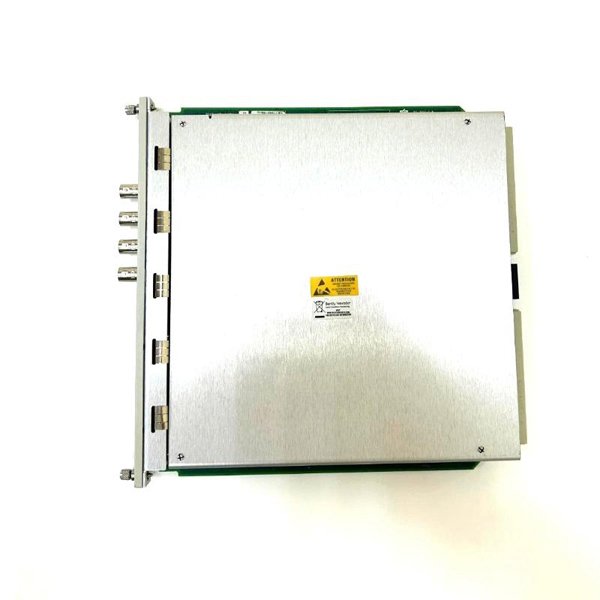

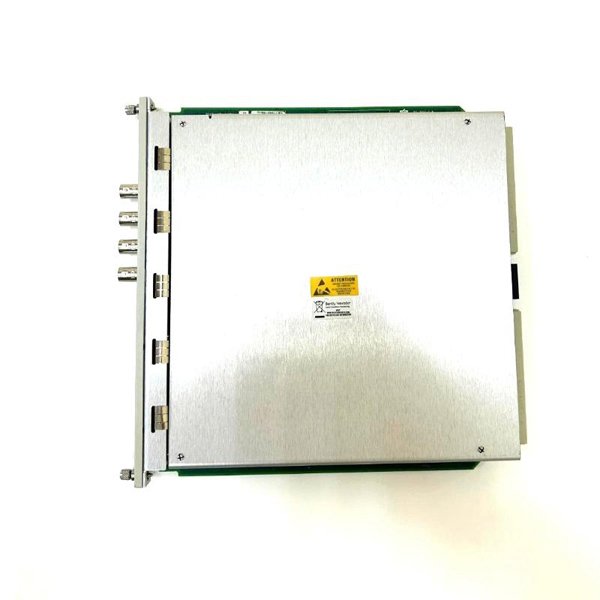

Bently Nevada 3500/42-04-CN Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42-04-CN

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:38

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42-04-CN Proximitor Seismic Monitor is an advanced vibration and position monitoring module designed for critical rotating machinery protection. It delivers real-time measurement and alarming functions for proximity probes and seismic transducers, ensuring machine health and operational safety in demanding industrial environments.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 3500/42-04-CN |

| Measurement Types | Radial Vibration, Thrust Position, Eccentricity, Shaft Position |

| Input Channels | 4 |

| Signal Type | Proximitor / Seismic |

| Accuracy | ±0.25% of full scale |

| Alarm Setpoints | 2 per channel (Alert, Danger) |

| Outputs | 4–20 mA proportional, relay contacts |

| Communication | Rack Interface to 3500 System |

| Power Consumption | ≤ 10 W |

| Operating Temperature | –30°C to +65°C |

| Dimensions (H × W × D) | 241.3 × 24.4 × 241.8 mm |

| Weight | 0.91 kg |

Applications

-

Continuous monitoring of steam turbines, compressors, pumps, and motors.

-

Shaft vibration and displacement tracking in high-value machinery.

-

Early fault detection in bearing systems and rotor dynamics.

-

Integration with plant-wide condition monitoring systems.

-

Compliance with API 670 for machinery protection.

Product Advantages

-

High Reliability: Industrial-grade design for 24/7 operation.

-

Flexible Configuration: Multiple measurement modes per channel.

-

Fast Response: Real-time alarming with minimal latency.

-

Integration Ready: Seamless connectivity with the 3500 Series framework.

-

Compliance: Meets stringent industrial monitoring standards.

FAQ

-

What sensors are compatible with the 3500/42-04-CN?

Proximity probes, velocity transducers, and accelerometers designed for Bently Nevada systems.

-

Can this module be used for thrust position monitoring?

Yes, it supports thrust position measurement with appropriate transducers.

-

Does it support redundant monitoring?

Yes, when configured in a redundant rack system.

-

How many alarm levels are available?

Two per channel: Alert and Danger.

-

Is it compliant with API 670?

Yes, it fully meets API 670 requirements.

-

Can the output be integrated into a DCS?

Yes, via 4–20 mA and relay outputs.

-

What is the accuracy of measurements?

±0.25% of full-scale output.

-

Does it require calibration?

Calibration is recommended during installation and periodic maintenance.

-

Can it operate in extreme temperatures?

Yes, from –30°C to +65°C.

-

Is firmware upgradeable?

Yes, through the 3500 rack system interface.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...