Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

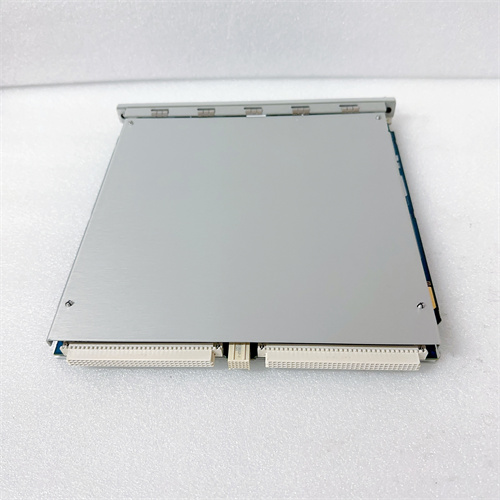

Bently Nevada 21000-16-10-15-088-03-02 Proximity Probe Housing Assemblies

Manufacturer:Bently Nevada

Product Number:21000-16-10-15-088-03-02

Product Type:Proximity Probe Housing Assemblies

Origin:USA

Housing Body Diameter:83.3 mm

Weight:1.1 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 21000-16-10-15-088-03-02 Proximity Probe Housing Assembly is an industrial-grade protective housing designed to secure proximity probes in critical rotating machinery environments. This assembly belongs to Bently Nevada’s well-established 21000 Series, trusted globally for reliable performance in applications where harsh environmental conditions, high vibration, and tight installation tolerances are prevalent.

With its precision-machined body and corrosion-resistant stainless steel construction, the housing provides a secure and environmentally sealed enclosure for eddy-current proximity probes used in condition monitoring and machinery protection systems. The 21000-16-10-15-088-03-02 model is specifically configured with optimized thread geometry and cable entry to facilitate easier installation and long-term durability in demanding industrial setups.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 21000-16-10-15-088-03-02 |

| Series | 21000 Series |

| Material | 316L Stainless Steel |

| Mounting Thread Type | 3/4-16 UNF |

| Cable Entry | Side-entry with sealed conduit fitting |

| Ingress Protection | IP66 / NEMA 4X |

| Operating Temperature Range | -40°C to +177°C (-40°F to +350°F) |

| Vibration Tolerance | Up to 50 g |

| Housing Body Diameter | 83.3 mm |

| Weight | 1.1 kg |

| Finish | Electro-polished |

| Seal Type | Dual O-ring + compression fitting |

| Compatible Probes | 3300 XL, 7200, 9000 series |

| Field Wiring | Internal terminal block |

| Certifications | ATEX, CE, CSA (depending on configuration) |

| Installation Orientation | Horizontal or vertical |

Product Applications

The 21000-16-10-15-088-03-02 housing is deployed in a variety of industrial applications where environmental protection and accurate sensor positioning are essential:

-

Turbomachinery Monitoring: Used on gas and steam turbines to house shaft vibration and thrust position probes.

-

Compressors and Pumps: Applied in critical process units where equipment failure can lead to unplanned shutdowns.

-

Petrochemical Plants: Installed in highly corrosive zones with chemical exposure and fluctuating temperatures.

-

Power Plants: Employed in coal-fired, nuclear, and combined cycle facilities for generator and turbine monitoring.

-

Steel Manufacturing: Used to monitor rotary kilns, mills, and gearboxes in high-temperature environments.

-

Marine & Offshore: Provides secure probe housing on marine propulsion systems and offshore drilling rigs.

Product Advantages

-

Corrosion Resistance: Made of high-grade 316L stainless steel with electro-polished surfaces for long service life in aggressive conditions.

-

Environmental Protection: Rated IP66/NEMA 4X to safeguard internal components from dust, water, and chemical ingress.

-

Precision Machining: Ensures accurate probe alignment, enhancing signal fidelity and reducing measurement drift.

-

Flexible Installation: Suitable for both horizontal and vertical mounting; accommodates various field configurations.

-

Serviceability: Internal wiring access and modular components enable easier installation and future maintenance.

-

Certified for Safety: Meets international standards for explosive environments with optional ATEX and CSA certifications.

Frequently Asked Questions (FAQ)

-

What type of probes can be installed in this housing?

It supports Bently Nevada 3300 XL, 7200, and 9000 proximity probes.

-

Is this model compliant with industrial protection standards?

Yes, it meets IP66 and NEMA 4X ratings for ingress protection.

-

Can this housing be used in Class I Div 2 hazardous areas?

Yes, when configured with appropriate certification options (e.g., ATEX or CSA).

-

How is the cable secured inside the housing?

A compression fitting and O-ring seal secure the cable entry against contaminants.

-

Does it support vertical installation on compressor casings?

Yes, it is designed for both horizontal and vertical orientations.

-

What distinguishes the -088-03-02 variant from similar models?

It features a slightly longer body and customized threading for deeper installation needs.

-

Can I access the probe or wiring after installation?

Yes, the housing provides internal access via a removable cap and terminal block.

-

Is vibration a concern for this assembly?

No, it withstands up to 50 g, suitable for most industrial vibration environments.

-

Does it require lubrication or periodic maintenance?

No lubrication is required. Routine inspection of seals is recommended.

-

How does this housing contribute to probe accuracy?

Its precise internal dimensions and mounting control ensure consistent probe-to-target gap and stable signal response.

Bently Nevada 21000-16-10-15-088-03-02 Proximity Probe Housing Assemblies

Manufacturer:Bently Nevada

Product Number:21000-16-10-15-088-03-02

Product Type:Proximity Probe Housing Assemblies

Origin:USA

Housing Body Diameter:83.3 mm

Weight:1.1 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 21000-16-10-15-088-03-02 Proximity Probe Housing Assembly is an industrial-grade protective housing designed to secure proximity probes in critical rotating machinery environments. This assembly belongs to Bently Nevada’s well-established 21000 Series, trusted globally for reliable performance in applications where harsh environmental conditions, high vibration, and tight installation tolerances are prevalent.

With its precision-machined body and corrosion-resistant stainless steel construction, the housing provides a secure and environmentally sealed enclosure for eddy-current proximity probes used in condition monitoring and machinery protection systems. The 21000-16-10-15-088-03-02 model is specifically configured with optimized thread geometry and cable entry to facilitate easier installation and long-term durability in demanding industrial setups.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 21000-16-10-15-088-03-02 |

| Series | 21000 Series |

| Material | 316L Stainless Steel |

| Mounting Thread Type | 3/4-16 UNF |

| Cable Entry | Side-entry with sealed conduit fitting |

| Ingress Protection | IP66 / NEMA 4X |

| Operating Temperature Range | -40°C to +177°C (-40°F to +350°F) |

| Vibration Tolerance | Up to 50 g |

| Housing Body Diameter | 83.3 mm |

| Weight | 1.1 kg |

| Finish | Electro-polished |

| Seal Type | Dual O-ring + compression fitting |

| Compatible Probes | 3300 XL, 7200, 9000 series |

| Field Wiring | Internal terminal block |

| Certifications | ATEX, CE, CSA (depending on configuration) |

| Installation Orientation | Horizontal or vertical |

Product Applications

The 21000-16-10-15-088-03-02 housing is deployed in a variety of industrial applications where environmental protection and accurate sensor positioning are essential:

-

Turbomachinery Monitoring: Used on gas and steam turbines to house shaft vibration and thrust position probes.

-

Compressors and Pumps: Applied in critical process units where equipment failure can lead to unplanned shutdowns.

-

Petrochemical Plants: Installed in highly corrosive zones with chemical exposure and fluctuating temperatures.

-

Power Plants: Employed in coal-fired, nuclear, and combined cycle facilities for generator and turbine monitoring.

-

Steel Manufacturing: Used to monitor rotary kilns, mills, and gearboxes in high-temperature environments.

-

Marine & Offshore: Provides secure probe housing on marine propulsion systems and offshore drilling rigs.

Product Advantages

-

Corrosion Resistance: Made of high-grade 316L stainless steel with electro-polished surfaces for long service life in aggressive conditions.

-

Environmental Protection: Rated IP66/NEMA 4X to safeguard internal components from dust, water, and chemical ingress.

-

Precision Machining: Ensures accurate probe alignment, enhancing signal fidelity and reducing measurement drift.

-

Flexible Installation: Suitable for both horizontal and vertical mounting; accommodates various field configurations.

-

Serviceability: Internal wiring access and modular components enable easier installation and future maintenance.

-

Certified for Safety: Meets international standards for explosive environments with optional ATEX and CSA certifications.

Frequently Asked Questions (FAQ)

-

What type of probes can be installed in this housing?

It supports Bently Nevada 3300 XL, 7200, and 9000 proximity probes.

-

Is this model compliant with industrial protection standards?

Yes, it meets IP66 and NEMA 4X ratings for ingress protection.

-

Can this housing be used in Class I Div 2 hazardous areas?

Yes, when configured with appropriate certification options (e.g., ATEX or CSA).

-

How is the cable secured inside the housing?

A compression fitting and O-ring seal secure the cable entry against contaminants.

-

Does it support vertical installation on compressor casings?

Yes, it is designed for both horizontal and vertical orientations.

-

What distinguishes the -088-03-02 variant from similar models?

It features a slightly longer body and customized threading for deeper installation needs.

-

Can I access the probe or wiring after installation?

Yes, the housing provides internal access via a removable cap and terminal block.

-

Is vibration a concern for this assembly?

No, it withstands up to 50 g, suitable for most industrial vibration environments.

-

Does it require lubrication or periodic maintenance?

No lubrication is required. Routine inspection of seals is recommended.

-

How does this housing contribute to probe accuracy?

Its precise internal dimensions and mounting control ensure consistent probe-to-target gap and stable signal response.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...