Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

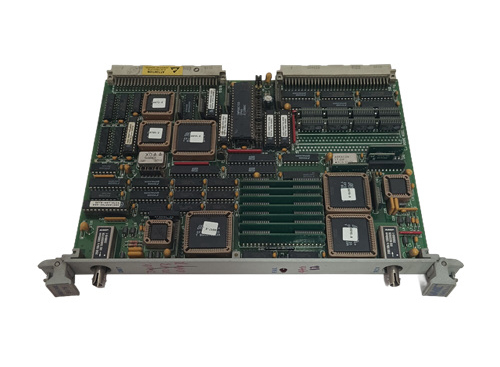

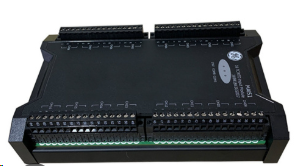

General Electric INTELLIX MO150 Transformer Monitoring System

Module Number:INTELLIX MO150

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

The General Electric INTELLIX MO150 Transformer Monitoring Module is an advanced monitoring system specifically designed for real-time monitoring of transformer status, preventing potential faults, and improving transformer reliability and operational efficiency. The following is a detailed analysis of the monitoring module:

Product Overview

Brand and Manufacturer: General Electric (General Electric Company)

Application areas: Widely used in large and medium-sized oil insulated transformers in transmission and distribution substations, power plants, and large industries.

Main function: Real time monitoring of transformer status, performing online transformer diagnosis, and preventing potential faults.

Technical features

Multi parameter monitoring

Support simultaneous monitoring of multiple parameters, such as vibration, temperature (including top and bottom oil temperatures), pressure, flow rate, load current, etc., to provide comprehensive equipment health status information.

Equipped with 8 analog inputs (4-20 mA or RTD PT100), 5 AC inputs (load and fan current), 2 digital inputs (system alarm, cooling control, and cooling alarm), and other interfaces.

Advanced diagnostic function

Use sensors and mathematical models based on IEEE and IEC standards to perform real-time online transformer diagnosis.

Integrate mathematical models of transformers for automatic calculations, including MVA models, winding hotspot temperature models, humidity and bubble models, insulation aging models, etc.

Data recording and analysis

Equipped with 10 years of memory storage for recording historical data, facilitating subsequent analysis, comparison, and evaluation.

May be equipped with powerful data analysis tools to identify potential issues and anomalies.

Intelligent control and warning

When an abnormal situation is detected, an alarm or notification may be triggered so that relevant personnel can take timely action.

Provide pre diagnosis and diagnostic modules to provide fault diagnosis recommendations and recommend actions to be taken in the event of a transformer alarm.

Easy to integrate and configure

It has good integrability and configuration flexibility, and can be easily integrated and configured with other industrial automation systems.

Supports multiple communication protocols and interfaces, such as the Hydran S2 gas and humidity sensor interface, making it easy to integrate with existing monitoring systems.

Economic benefits

Reduce maintenance costs: By real-time monitoring and diagnosis, reduce the occurrence of sudden and catastrophic accidents, and avoid expensive replacement and cleaning costs.

Improve production efficiency: avoid unplanned power outages, extend the time interval between two routine inspections, and reduce maintenance and repair costs.

Extend equipment lifespan: optimize equipment lifespan by monitoring cooling system performance; Real time provision of transformer status information using online models to better extend transformer lifespan.

Applicable scenarios

The General Electric INTELLIX MO150 transformer monitoring module is suitable for power supply systems that require precise monitoring of transformer status, such as power stations, factories, etc.

In summary, the General Electric INTELLIX MO150 transformer monitoring module is an intelligent and cost-effective solution that integrates multiple advanced technologies and functions, providing strong support for real-time monitoring, fault diagnosis, and preventive maintenance of transformers.

General Electric INTELLIX MO150 Transformer Monitoring System

Module Number:INTELLIX MO150

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

The General Electric INTELLIX MO150 Transformer Monitoring Module is an advanced monitoring system specifically designed for real-time monitoring of transformer status, preventing potential faults, and improving transformer reliability and operational efficiency. The following is a detailed analysis of the monitoring module:

Product Overview

Brand and Manufacturer: General Electric (General Electric Company)

Application areas: Widely used in large and medium-sized oil insulated transformers in transmission and distribution substations, power plants, and large industries.

Main function: Real time monitoring of transformer status, performing online transformer diagnosis, and preventing potential faults.

Technical features

Multi parameter monitoring

Support simultaneous monitoring of multiple parameters, such as vibration, temperature (including top and bottom oil temperatures), pressure, flow rate, load current, etc., to provide comprehensive equipment health status information.

Equipped with 8 analog inputs (4-20 mA or RTD PT100), 5 AC inputs (load and fan current), 2 digital inputs (system alarm, cooling control, and cooling alarm), and other interfaces.

Advanced diagnostic function

Use sensors and mathematical models based on IEEE and IEC standards to perform real-time online transformer diagnosis.

Integrate mathematical models of transformers for automatic calculations, including MVA models, winding hotspot temperature models, humidity and bubble models, insulation aging models, etc.

Data recording and analysis

Equipped with 10 years of memory storage for recording historical data, facilitating subsequent analysis, comparison, and evaluation.

May be equipped with powerful data analysis tools to identify potential issues and anomalies.

Intelligent control and warning

When an abnormal situation is detected, an alarm or notification may be triggered so that relevant personnel can take timely action.

Provide pre diagnosis and diagnostic modules to provide fault diagnosis recommendations and recommend actions to be taken in the event of a transformer alarm.

Easy to integrate and configure

It has good integrability and configuration flexibility, and can be easily integrated and configured with other industrial automation systems.

Supports multiple communication protocols and interfaces, such as the Hydran S2 gas and humidity sensor interface, making it easy to integrate with existing monitoring systems.

Economic benefits

Reduce maintenance costs: By real-time monitoring and diagnosis, reduce the occurrence of sudden and catastrophic accidents, and avoid expensive replacement and cleaning costs.

Improve production efficiency: avoid unplanned power outages, extend the time interval between two routine inspections, and reduce maintenance and repair costs.

Extend equipment lifespan: optimize equipment lifespan by monitoring cooling system performance; Real time provision of transformer status information using online models to better extend transformer lifespan.

Applicable scenarios

The General Electric INTELLIX MO150 transformer monitoring module is suitable for power supply systems that require precise monitoring of transformer status, such as power stations, factories, etc.

In summary, the General Electric INTELLIX MO150 transformer monitoring module is an intelligent and cost-effective solution that integrates multiple advanced technologies and functions, providing strong support for real-time monitoring, fault diagnosis, and preventive maintenance of transformers.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...