Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

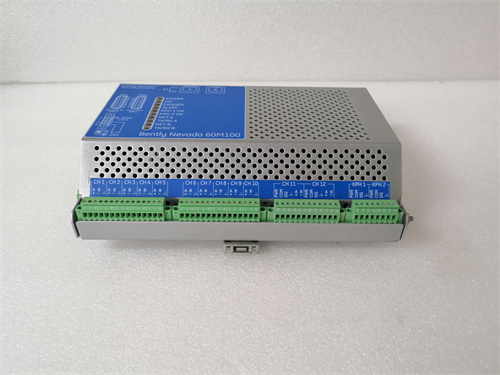

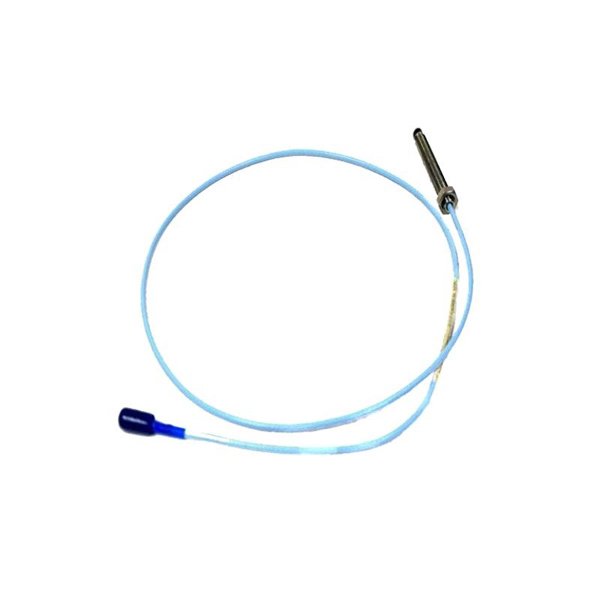

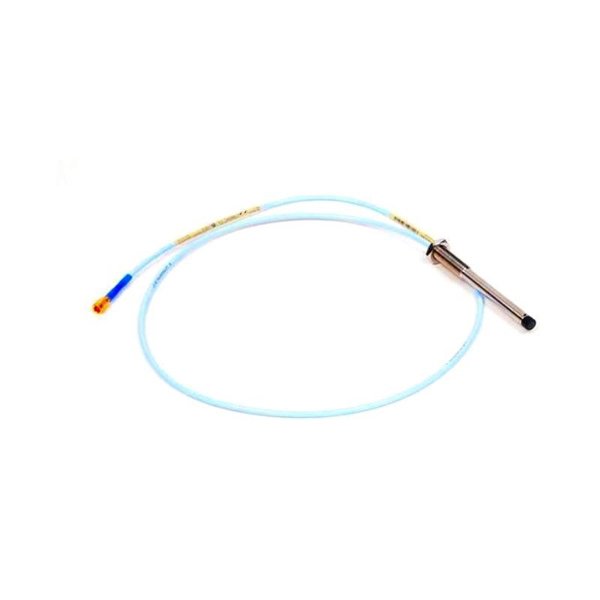

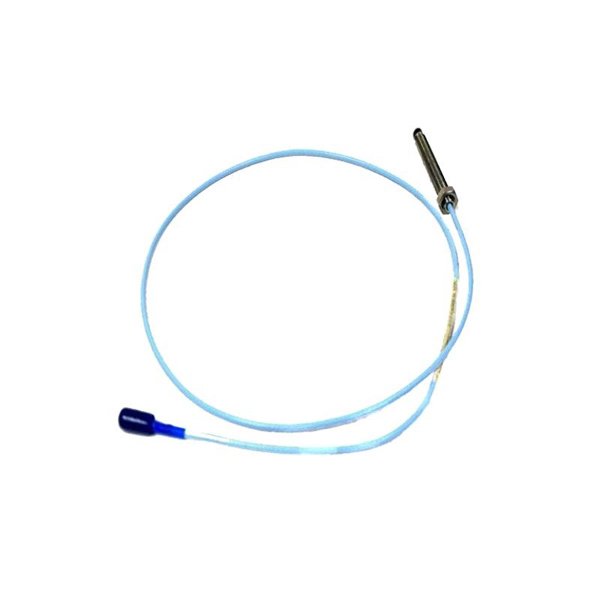

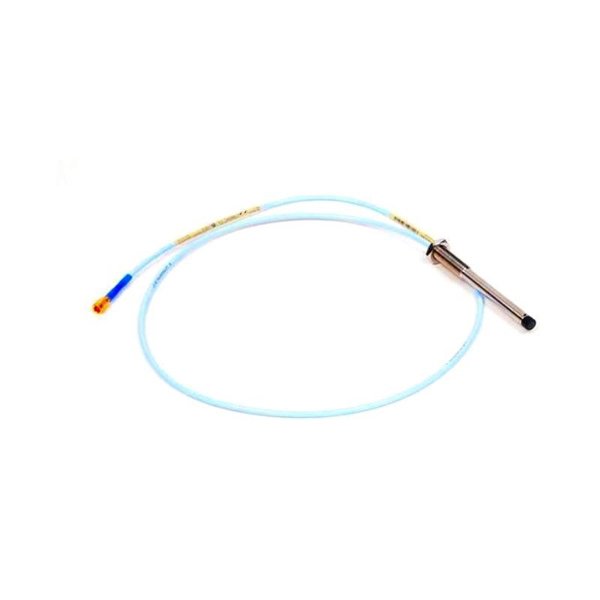

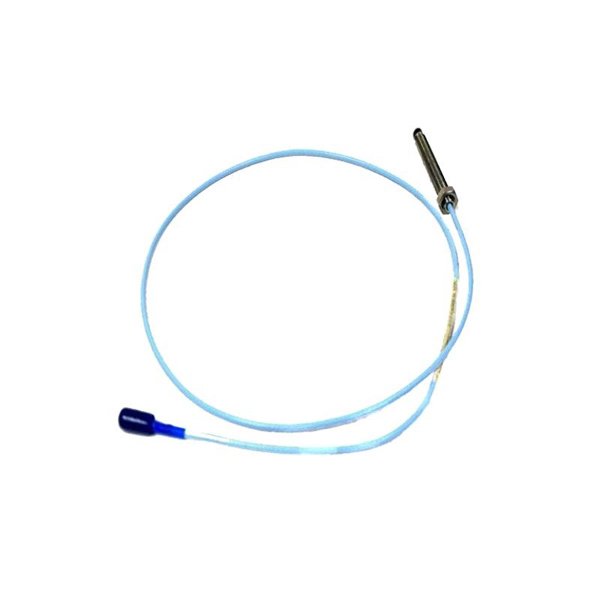

Bently Nevada 330101-00-43-10-02-CN 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330101-00-43-10-02-CN

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:1 meter

Weight:0.323 kg

Views:40

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-00-43-10-02-CN is a high-performance proximity probe from the 3300 XL 8mm series, engineered for precise, non-contact measurement of shaft vibration and position in rotating machinery. Widely adopted in the energy, petrochemical, and manufacturing sectors, this probe plays a critical role in real-time condition monitoring and machinery protection.

This specific model features a 1 meter total length, and includes configuration code “02” (typically referring to connector type and approvals). Designed for use in harsh industrial environments, the 3300 XL probes are known for their exceptional durability, high accuracy, and seamless integration with Bently Nevada’s monitoring systems.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330101-00-43-10-02-CN |

| Series | Bently Nevada 3300 XL 8mm |

| Probe Tip Diameter | 8 mm |

| Sensing Range | 2 mm (80 mils), with linear output over 200 mils |

| Total Length | 1 meter |

| Connector Type | ClickLoc™ with “02” configuration (varies per region/approval) |

| Target Material | Ferromagnetic (commonly 4140 steel) |

| Output Signal | -200 mV/mil (-7.87 mV/µm) ±5% |

| Thread Type | 1/4-28 UNF or M8x1 (thread length as per configuration) |

| Mounting Method | Threaded into brackets or direct to machine housing |

| Operating Temperature | -35°C to +177°C |

| Storage Temperature | -51°C to +177°C |

| Frequency Response | DC to 10 kHz |

| Environmental Rating | IP68 / NEMA 6P |

| Compliance | CE, RoHS, ATEX (CN code indicates China-specific compliance) |

| Weight | 0.323 kg |

Product Applications

The 330101-00-43-10-02-CN proximity probe is designed for deployment in a wide range of industrial applications:

-

Gas and Steam Turbines

Detects shaft movement and vibrational anomalies to protect rotor dynamics.

-

Compressors and Expanders

Ensures early detection of imbalance, misalignment, or shaft rub.

-

Electric Generators and Motors

Used for shaft positioning, displacement monitoring, and predictive maintenance.

-

Industrial Pumps

Helps prevent unplanned failures by tracking bearing and shaft condition.

-

Refining & Petrochemical Plants

Core component of vibration monitoring systems integrated with DCS/SCADA.

-

Mining and Metal Processing Equipment

Monitors large rotating equipment where continuous performance is essential.

Product Advantages

-

Exceptional Reliability

Proven durability even in corrosive, high-temperature, or submerged environments.

-

Factory-Calibrated System Matching

Probe, extension cable, and Proximitor® are matched to ensure linearity and accuracy.

-

IP68 Protection Rating

Suitable for use in environments with oil, dust, moisture, or underwater applications.

-

Color-Coded ClickLoc™ Connectors

Ensures secure connection, minimizes human error during installation.

-

Broad Industrial Compatibility

Integrates easily with Bently Nevada 3500 Series, System 1®, and other monitoring platforms.

-

Simplified Maintenance

Long service life and modular cable system reduce maintenance complexity and cost.

Frequently Asked Questions (FAQ)

-

Is the 330101-00-43-10-02-CN probe pre-calibrated?

Yes, it’s factory-matched and calibrated as a system with its extension cable and Proximitor® sensor.

-

Can this model be used in applications with chemical exposure?

Yes, the stainless steel housing and sealed connector system make it resistant to most industrial chemicals.

-

What is the recommended torque for installation?

For the 1/4-28 thread, use around 1.5–2.0 N·m (13–18 in-lb) to avoid over-tightening.

-

What is the “CN” suffix in the part number?

It typically indicates compliance with Chinese regulatory and certification standards.

-

Does the cable length impact accuracy?

Yes, the probe and extension cable must be used together as specified. Mixing lengths can distort calibration.

-

Is this probe hot-swappable?

No. Always shut down monitoring systems before disconnecting the probe to prevent signal error or system faults.

-

How can I verify proper probe gap during installation?

Use a micrometer tool or feeler gauge and check for the standard -8 VDC output at the desired gap (usually 2 mm).

-

Can I cut or modify the probe cable?

No, cables are pre-terminated and matched. Modifying length or connectors voids calibration and may damage the system.

-

What should I do if the probe output voltage is unstable?

Check cable integrity, grounding, and ensure the probe is securely mounted and aimed at a clean, ferrous target surface.

-

Is this product compatible with wireless vibration transmitters?

Not directly. It’s designed for wired Proximitor® systems, but data can be fed into wireless transmitters via compatible interfaces.

Bently Nevada 330101-00-43-10-02-CN 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330101-00-43-10-02-CN

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:1 meter

Weight:0.323 kg

Views:40

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-00-43-10-02-CN is a high-performance proximity probe from the 3300 XL 8mm series, engineered for precise, non-contact measurement of shaft vibration and position in rotating machinery. Widely adopted in the energy, petrochemical, and manufacturing sectors, this probe plays a critical role in real-time condition monitoring and machinery protection.

This specific model features a 1 meter total length, and includes configuration code “02” (typically referring to connector type and approvals). Designed for use in harsh industrial environments, the 3300 XL probes are known for their exceptional durability, high accuracy, and seamless integration with Bently Nevada’s monitoring systems.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330101-00-43-10-02-CN |

| Series | Bently Nevada 3300 XL 8mm |

| Probe Tip Diameter | 8 mm |

| Sensing Range | 2 mm (80 mils), with linear output over 200 mils |

| Total Length | 1 meter |

| Connector Type | ClickLoc™ with “02” configuration (varies per region/approval) |

| Target Material | Ferromagnetic (commonly 4140 steel) |

| Output Signal | -200 mV/mil (-7.87 mV/µm) ±5% |

| Thread Type | 1/4-28 UNF or M8x1 (thread length as per configuration) |

| Mounting Method | Threaded into brackets or direct to machine housing |

| Operating Temperature | -35°C to +177°C |

| Storage Temperature | -51°C to +177°C |

| Frequency Response | DC to 10 kHz |

| Environmental Rating | IP68 / NEMA 6P |

| Compliance | CE, RoHS, ATEX (CN code indicates China-specific compliance) |

| Weight | 0.323 kg |

Product Applications

The 330101-00-43-10-02-CN proximity probe is designed for deployment in a wide range of industrial applications:

-

Gas and Steam Turbines

Detects shaft movement and vibrational anomalies to protect rotor dynamics.

-

Compressors and Expanders

Ensures early detection of imbalance, misalignment, or shaft rub.

-

Electric Generators and Motors

Used for shaft positioning, displacement monitoring, and predictive maintenance.

-

Industrial Pumps

Helps prevent unplanned failures by tracking bearing and shaft condition.

-

Refining & Petrochemical Plants

Core component of vibration monitoring systems integrated with DCS/SCADA.

-

Mining and Metal Processing Equipment

Monitors large rotating equipment where continuous performance is essential.

Product Advantages

-

Exceptional Reliability

Proven durability even in corrosive, high-temperature, or submerged environments.

-

Factory-Calibrated System Matching

Probe, extension cable, and Proximitor® are matched to ensure linearity and accuracy.

-

IP68 Protection Rating

Suitable for use in environments with oil, dust, moisture, or underwater applications.

-

Color-Coded ClickLoc™ Connectors

Ensures secure connection, minimizes human error during installation.

-

Broad Industrial Compatibility

Integrates easily with Bently Nevada 3500 Series, System 1®, and other monitoring platforms.

-

Simplified Maintenance

Long service life and modular cable system reduce maintenance complexity and cost.

Frequently Asked Questions (FAQ)

-

Is the 330101-00-43-10-02-CN probe pre-calibrated?

Yes, it’s factory-matched and calibrated as a system with its extension cable and Proximitor® sensor.

-

Can this model be used in applications with chemical exposure?

Yes, the stainless steel housing and sealed connector system make it resistant to most industrial chemicals.

-

What is the recommended torque for installation?

For the 1/4-28 thread, use around 1.5–2.0 N·m (13–18 in-lb) to avoid over-tightening.

-

What is the “CN” suffix in the part number?

It typically indicates compliance with Chinese regulatory and certification standards.

-

Does the cable length impact accuracy?

Yes, the probe and extension cable must be used together as specified. Mixing lengths can distort calibration.

-

Is this probe hot-swappable?

No. Always shut down monitoring systems before disconnecting the probe to prevent signal error or system faults.

-

How can I verify proper probe gap during installation?

Use a micrometer tool or feeler gauge and check for the standard -8 VDC output at the desired gap (usually 2 mm).

-

Can I cut or modify the probe cable?

No, cables are pre-terminated and matched. Modifying length or connectors voids calibration and may damage the system.

-

What should I do if the probe output voltage is unstable?

Check cable integrity, grounding, and ensure the probe is securely mounted and aimed at a clean, ferrous target surface.

-

Is this product compatible with wireless vibration transmitters?

Not directly. It’s designed for wired Proximitor® systems, but data can be fed into wireless transmitters via compatible interfaces.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...