Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

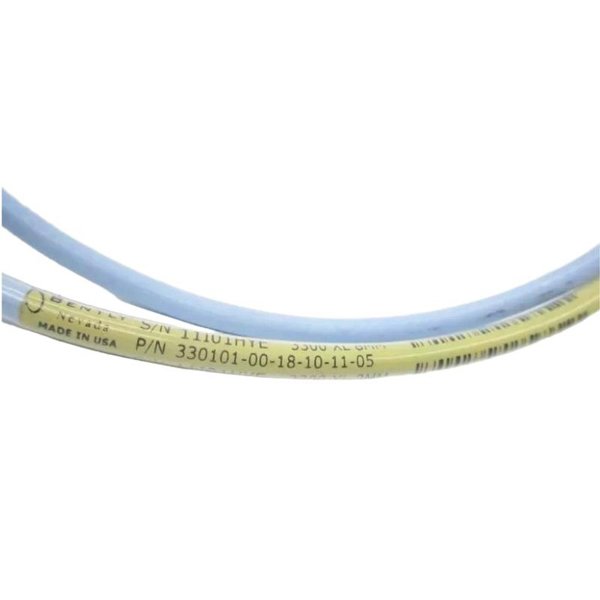

Bently Nevada 330101-00-18-10-11-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330101-00-18-10-11-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:1 m

Weight:0.323 kg

Views:43

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-00-18-10-11-05 is a part of the renowned 3300 XL 8 mm Proximity Transducer System, engineered by Bently Nevada, a global leader in condition monitoring and asset protection. This probe is specifically designed to measure the distance between the probe tip and a conductive target such as a rotating shaft, enabling real-time monitoring of vibration, displacement, and shaft position.

This model is widely implemented in high-value rotating equipment such as turbines, compressors, pumps, and motors, particularly where accuracy, reliability, and harsh-environment performance are essential. The 330101-00-18-10-11-05 variant features an 18-foot cable, optimized sensitivity, and ruggedized design, delivering consistent output in compliance with API 670 standards.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330101-00-18-10-11-05 |

| Product Type | Proximity Probe |

| Series | 3300 XL |

| Tip Diameter | 8 mm |

| Tip Material | Polyphenylene Sulfide (PPS) |

| Body Material | AISI 304 Stainless Steel |

| Thread Size | 3/8-24 UNF-2A |

| Output Signal | -200 mV/mil |

| System Accuracy | ±0.07 mm typical |

| Total Length | 1 meter |

| Connector Type | Miniature coaxial |

| Temperature Range | -35°C to +177°C (-31°F to +351°F) |

| Vibration Limit | 50 g peak |

| Pressure Rating | 500 psi max |

| EMI/RFI Immunity | High immunity, meets industrial shielding standards |

| Compliance Standards | API 670, CE, RoHS |

| Weight | 0.323 kg |

Product Applications

The 330101-00-18-10-11-05 is tailored for use in a range of industrial machinery and critical asset monitoring applications:

-

Steam and Gas Turbines

Tracks shaft displacement and vibration for real-time protection and diagnostics.

-

Centrifugal and Reciprocating Compressors

Enables early failure detection in bearings and rotor assemblies.

-

Electric Motors and Generators

Ensures optimal rotor alignment and dynamic balance.

-

Pumps and Fans

Detects mechanical issues such as imbalance, misalignment, or cavitation.

-

Gearboxes and Transmission Systems

Monitors gear mesh frequencies and shaft conditions.

-

Oil & Gas, Petrochemical, and Power Plants

Deployed in safety-critical and mission-critical equipment environments.

Product Advantages

-

Precision Engineering

Delivers high accuracy with minimal deviation across wide operating conditions.

-

Extended Temperature Range

Suitable for harsh ambient conditions typical of heavy-duty industrial settings.

-

Rugged Design

Made with corrosion-resistant stainless steel and PPS tip, designed to withstand pressure and vibration.

-

API 670 Compliant

Fully conforms to the global standard for machinery protection.

-

Matched System Integration

Designed to work seamlessly with Bently Nevada extension cables and proximitors.

-

Signal Stability

Provides excellent linear output, reducing measurement error even with cable lengths over 15 ft.

-

Easy Installation

Threaded body and miniature connectors simplify mounting and maintenance.

-

Electromagnetic Interference Resistant

Shielded construction minimizes false readings in electrically noisy environments.

-

Maintenance-Free

Non-contact measurement ensures long operational life with minimal servicing.

-

Scalable Configuration

Compatible with a wide range of Bently Nevada 3300 XL monitoring systems.

Frequently Asked Questions (FAQ)

-

What makes the 330101-00-18-10-11-05 different from other proximity probes?

This model offers an 18-foot cable, ideal for medium-range installations, with optimized EMI shielding and compliance with API 670.

-

Is the probe tip replaceable or serviceable?

No. The tip is fixed and factory-calibrated. For failures, the entire probe must be replaced.

-

Can this probe be used for both axial and radial measurements?

Yes, depending on the mounting position, it can measure both directions of shaft movement.

-

How do I ensure proper calibration when replacing this probe?

Always replace with a matched system (probe, extension cable, and driver) to maintain accurate calibration.

-

Is the probe hazardous area certified?

The probe itself may not carry ATEX/IECEx certification, but matched systems often are. Always check driver specifications for hazardous certifications.

-

What type of connector is used on the probe?

It uses a miniature coaxial connector that interfaces with 3300 XL extension cables.

-

How should the probe be mounted for optimal accuracy?

Ensure flush contact with the mounting bracket, secure locknut placement, and avoid cable bending near the connector.

-

Can I use this probe with third-party condition monitoring systems?

While physically possible, accuracy and calibration may be compromised. It’s recommended to use Bently Nevada systems.

-

What is the probe’s linear range?

The typical linear sensing range is up to 2 mm, optimized for 8 mm tip diameter targets.

-

Does Bently Nevada provide field support for this product?

Yes, Bently Nevada offers global technical support and field calibration services for 3300 XL systems.

Bently Nevada 330101-00-18-10-11-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330101-00-18-10-11-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:1 m

Weight:0.323 kg

Views:43

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-00-18-10-11-05 is a part of the renowned 3300 XL 8 mm Proximity Transducer System, engineered by Bently Nevada, a global leader in condition monitoring and asset protection. This probe is specifically designed to measure the distance between the probe tip and a conductive target such as a rotating shaft, enabling real-time monitoring of vibration, displacement, and shaft position.

This model is widely implemented in high-value rotating equipment such as turbines, compressors, pumps, and motors, particularly where accuracy, reliability, and harsh-environment performance are essential. The 330101-00-18-10-11-05 variant features an 18-foot cable, optimized sensitivity, and ruggedized design, delivering consistent output in compliance with API 670 standards.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330101-00-18-10-11-05 |

| Product Type | Proximity Probe |

| Series | 3300 XL |

| Tip Diameter | 8 mm |

| Tip Material | Polyphenylene Sulfide (PPS) |

| Body Material | AISI 304 Stainless Steel |

| Thread Size | 3/8-24 UNF-2A |

| Output Signal | -200 mV/mil |

| System Accuracy | ±0.07 mm typical |

| Total Length | 1 meter |

| Connector Type | Miniature coaxial |

| Temperature Range | -35°C to +177°C (-31°F to +351°F) |

| Vibration Limit | 50 g peak |

| Pressure Rating | 500 psi max |

| EMI/RFI Immunity | High immunity, meets industrial shielding standards |

| Compliance Standards | API 670, CE, RoHS |

| Weight | 0.323 kg |

Product Applications

The 330101-00-18-10-11-05 is tailored for use in a range of industrial machinery and critical asset monitoring applications:

-

Steam and Gas Turbines

Tracks shaft displacement and vibration for real-time protection and diagnostics.

-

Centrifugal and Reciprocating Compressors

Enables early failure detection in bearings and rotor assemblies.

-

Electric Motors and Generators

Ensures optimal rotor alignment and dynamic balance.

-

Pumps and Fans

Detects mechanical issues such as imbalance, misalignment, or cavitation.

-

Gearboxes and Transmission Systems

Monitors gear mesh frequencies and shaft conditions.

-

Oil & Gas, Petrochemical, and Power Plants

Deployed in safety-critical and mission-critical equipment environments.

Product Advantages

-

Precision Engineering

Delivers high accuracy with minimal deviation across wide operating conditions.

-

Extended Temperature Range

Suitable for harsh ambient conditions typical of heavy-duty industrial settings.

-

Rugged Design

Made with corrosion-resistant stainless steel and PPS tip, designed to withstand pressure and vibration.

-

API 670 Compliant

Fully conforms to the global standard for machinery protection.

-

Matched System Integration

Designed to work seamlessly with Bently Nevada extension cables and proximitors.

-

Signal Stability

Provides excellent linear output, reducing measurement error even with cable lengths over 15 ft.

-

Easy Installation

Threaded body and miniature connectors simplify mounting and maintenance.

-

Electromagnetic Interference Resistant

Shielded construction minimizes false readings in electrically noisy environments.

-

Maintenance-Free

Non-contact measurement ensures long operational life with minimal servicing.

-

Scalable Configuration

Compatible with a wide range of Bently Nevada 3300 XL monitoring systems.

Frequently Asked Questions (FAQ)

-

What makes the 330101-00-18-10-11-05 different from other proximity probes?

This model offers an 18-foot cable, ideal for medium-range installations, with optimized EMI shielding and compliance with API 670.

-

Is the probe tip replaceable or serviceable?

No. The tip is fixed and factory-calibrated. For failures, the entire probe must be replaced.

-

Can this probe be used for both axial and radial measurements?

Yes, depending on the mounting position, it can measure both directions of shaft movement.

-

How do I ensure proper calibration when replacing this probe?

Always replace with a matched system (probe, extension cable, and driver) to maintain accurate calibration.

-

Is the probe hazardous area certified?

The probe itself may not carry ATEX/IECEx certification, but matched systems often are. Always check driver specifications for hazardous certifications.

-

What type of connector is used on the probe?

It uses a miniature coaxial connector that interfaces with 3300 XL extension cables.

-

How should the probe be mounted for optimal accuracy?

Ensure flush contact with the mounting bracket, secure locknut placement, and avoid cable bending near the connector.

-

Can I use this probe with third-party condition monitoring systems?

While physically possible, accuracy and calibration may be compromised. It’s recommended to use Bently Nevada systems.

-

What is the probe’s linear range?

The typical linear sensing range is up to 2 mm, optimized for 8 mm tip diameter targets.

-

Does Bently Nevada provide field support for this product?

Yes, Bently Nevada offers global technical support and field calibration services for 3300 XL systems.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...