Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

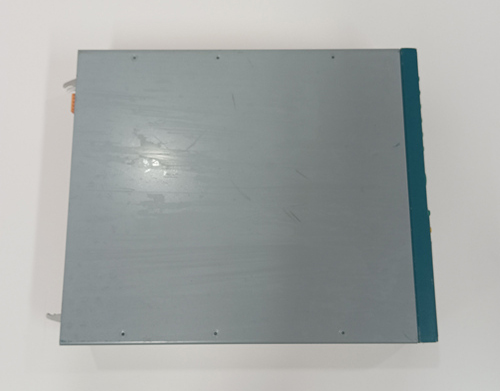

Bently Nevada 3500/72M 140471-01 Recip Rod Position Monitor

Manufacturer:Bently Nevada

Product Number:3500/72M 140471-01

Product Type:Recip Rod Position Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 99.1 mm

Weight:0.2 kg

Views:59

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/72M 140471-01 Recip Rod Position Monitor is a specialized module designed to measure the position of reciprocating rods in reciprocating compressors. It is part of the trusted 3500 Series Machinery Protection System and provides critical insight into the mechanical condition of compressor pistons, connecting rods, and crosshead assemblies. The 3500/72M is specifically tailored for monitoring rod drop and rod position, two parameters essential for detecting excessive wear, misalignment, and developing mechanical faults in reciprocating machinery.

Installed within the 3500 rack, this module integrates seamlessly with proximity transducers and other 3500 monitoring hardware. It enables users to establish predictive maintenance schedules, enhance safety, and minimize costly failures by providing accurate and continuous rod position data.

Product Parameters

| Parameter | Value |

|---|---|

| Model | 3500/72M |

| Part Number | 140471-01 |

| Dimensions | 241.3 x 24.4 x 99.1 mm |

| Weight | 0.2 kg |

| Power Consumption | < 7 watts |

| Input Channels | 2 per module |

| Transducer Compatibility | Works with 3300 XL series proximity transducers |

| Rod Position Range | ±2.0 mm (typical) |

| Output Type | Buffered output and 4–20 mA output |

| Configuration Interface | 3500/01 or 3500/03 Display or via software |

| Mounting Method | 3500 rack slot |

| Environmental Compliance | Meets IEC 61000 and CE directives |

Product Applications

The 3500/72M Rod Position Monitor is used in the following applications:

-

Reciprocating Compressor Protection: Tracks piston rod movement, detecting wear or mechanical failure early.

-

Rod Drop Monitoring: Measures downward movement of the crosshead assembly to identify abnormal friction or alignment problems.

-

Predictive Maintenance: Enables trending of rod position data to proactively schedule maintenance before failures occur.

-

Petrochemical Plants: Used extensively in reciprocating compressors for hydrocarbon processing.

-

Gas Transmission Stations: Ensures operational safety of large compressors moving natural gas through pipelines.

-

Oil Refining Operations: Monitors critical reciprocating equipment involved in refining operations.

Product Advantages

-

Dedicated Rod Position Monitoring – Specifically engineered for reciprocating machines, offering precise tracking of rod movement.

-

Dual Channel Support – Each module monitors two rod positions simultaneously, saving rack space and improving system scalability.

-

Buffered and Current Outputs – Provides both buffered signals for detailed diagnostics and 4–20 mA outputs for DCS/PLC integration.

-

Rack Integration – Fully compatible with the Bently Nevada 3500 rack architecture, simplifying deployment and power management.

-

Diagnostic Alarms – Configurable alarm limits allow quick detection of abnormal rod drop or deviation.

-

High Compatibility – Operates with Bently Nevada’s 3300 XL proximity probe series for maximum measurement reliability.

-

Modular Design – Easily replaceable module design ensures fast servicing and minimal system downtime.

-

Compact and Lightweight – With a slim profile (24.4 mm width) and lightweight form factor (0.2 kg), it’s ideal for high-density installations.

-

Environmentally Robust – Designed to comply with industrial EMI, electrical, and mechanical standards.

-

Continuous Monitoring – Provides real-time rod position data critical for maintaining machine reliability and operational efficiency.

FAQs

Q1: What does the 3500/72M monitor?

A1: It monitors the position and rod drop of reciprocating rods in reciprocating compressors.

Q2: How many channels are available per module?

A2: Each module supports 2 independent monitoring channels.

Q3: Which sensors are compatible with the 3500/72M?

A3: It is compatible with Bently Nevada’s 3300 XL proximity probe series.

Q4: What type of outputs does it provide?

A4: The module provides buffered output signals and 4–20 mA current loop outputs.

Q5: Can I configure alarm thresholds?

A5: Yes, alarm thresholds for rod drop or deviation can be set via the system interface.

Q6: How is it installed?

A6: The module is installed in a dedicated slot within the 3500 monitoring rack.

Q7: What is the typical rod position monitoring range?

A7: The typical rod position monitoring range is ±2.0 mm.

Q8: Is the 3500/72M hot-swappable?

A8: Yes, it can be replaced while the system is operating, minimizing downtime.

Q9: Does it require external power?

A9: No, it draws power directly from the 3500 rack.

Q10: What industries typically use this module?

A10: It is widely used in oil & gas, petrochemical, gas compression, and refining industries.

Bently Nevada 3500/72M 140471-01 Recip Rod Position Monitor

Manufacturer:Bently Nevada

Product Number:3500/72M 140471-01

Product Type:Recip Rod Position Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 99.1 mm

Weight:0.2 kg

Views:59

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/72M 140471-01 Recip Rod Position Monitor is a specialized module designed to measure the position of reciprocating rods in reciprocating compressors. It is part of the trusted 3500 Series Machinery Protection System and provides critical insight into the mechanical condition of compressor pistons, connecting rods, and crosshead assemblies. The 3500/72M is specifically tailored for monitoring rod drop and rod position, two parameters essential for detecting excessive wear, misalignment, and developing mechanical faults in reciprocating machinery.

Installed within the 3500 rack, this module integrates seamlessly with proximity transducers and other 3500 monitoring hardware. It enables users to establish predictive maintenance schedules, enhance safety, and minimize costly failures by providing accurate and continuous rod position data.

Product Parameters

| Parameter | Value |

|---|---|

| Model | 3500/72M |

| Part Number | 140471-01 |

| Dimensions | 241.3 x 24.4 x 99.1 mm |

| Weight | 0.2 kg |

| Power Consumption | < 7 watts |

| Input Channels | 2 per module |

| Transducer Compatibility | Works with 3300 XL series proximity transducers |

| Rod Position Range | ±2.0 mm (typical) |

| Output Type | Buffered output and 4–20 mA output |

| Configuration Interface | 3500/01 or 3500/03 Display or via software |

| Mounting Method | 3500 rack slot |

| Environmental Compliance | Meets IEC 61000 and CE directives |

Product Applications

The 3500/72M Rod Position Monitor is used in the following applications:

-

Reciprocating Compressor Protection: Tracks piston rod movement, detecting wear or mechanical failure early.

-

Rod Drop Monitoring: Measures downward movement of the crosshead assembly to identify abnormal friction or alignment problems.

-

Predictive Maintenance: Enables trending of rod position data to proactively schedule maintenance before failures occur.

-

Petrochemical Plants: Used extensively in reciprocating compressors for hydrocarbon processing.

-

Gas Transmission Stations: Ensures operational safety of large compressors moving natural gas through pipelines.

-

Oil Refining Operations: Monitors critical reciprocating equipment involved in refining operations.

Product Advantages

-

Dedicated Rod Position Monitoring – Specifically engineered for reciprocating machines, offering precise tracking of rod movement.

-

Dual Channel Support – Each module monitors two rod positions simultaneously, saving rack space and improving system scalability.

-

Buffered and Current Outputs – Provides both buffered signals for detailed diagnostics and 4–20 mA outputs for DCS/PLC integration.

-

Rack Integration – Fully compatible with the Bently Nevada 3500 rack architecture, simplifying deployment and power management.

-

Diagnostic Alarms – Configurable alarm limits allow quick detection of abnormal rod drop or deviation.

-

High Compatibility – Operates with Bently Nevada’s 3300 XL proximity probe series for maximum measurement reliability.

-

Modular Design – Easily replaceable module design ensures fast servicing and minimal system downtime.

-

Compact and Lightweight – With a slim profile (24.4 mm width) and lightweight form factor (0.2 kg), it’s ideal for high-density installations.

-

Environmentally Robust – Designed to comply with industrial EMI, electrical, and mechanical standards.

-

Continuous Monitoring – Provides real-time rod position data critical for maintaining machine reliability and operational efficiency.

FAQs

Q1: What does the 3500/72M monitor?

A1: It monitors the position and rod drop of reciprocating rods in reciprocating compressors.

Q2: How many channels are available per module?

A2: Each module supports 2 independent monitoring channels.

Q3: Which sensors are compatible with the 3500/72M?

A3: It is compatible with Bently Nevada’s 3300 XL proximity probe series.

Q4: What type of outputs does it provide?

A4: The module provides buffered output signals and 4–20 mA current loop outputs.

Q5: Can I configure alarm thresholds?

A5: Yes, alarm thresholds for rod drop or deviation can be set via the system interface.

Q6: How is it installed?

A6: The module is installed in a dedicated slot within the 3500 monitoring rack.

Q7: What is the typical rod position monitoring range?

A7: The typical rod position monitoring range is ±2.0 mm.

Q8: Is the 3500/72M hot-swappable?

A8: Yes, it can be replaced while the system is operating, minimizing downtime.

Q9: Does it require external power?

A9: No, it draws power directly from the 3500 rack.

Q10: What industries typically use this module?

A10: It is widely used in oil & gas, petrochemical, gas compression, and refining industries.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...