Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

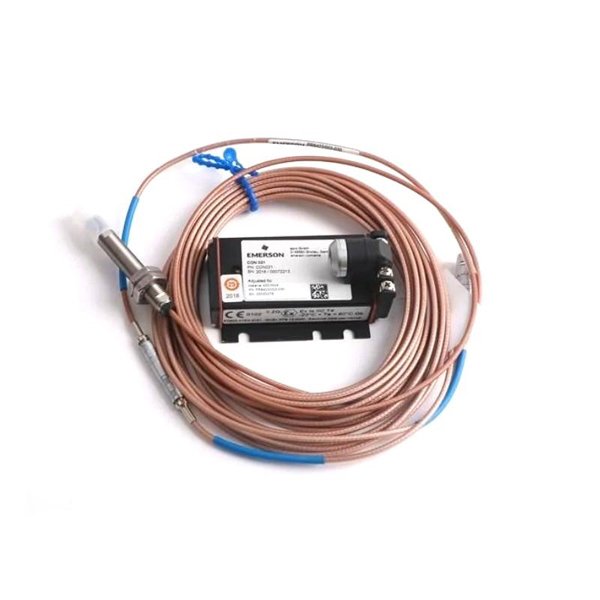

Epro PR6424/000-140+CON021 16mm Eddy Current Sensor

Manufacturer:Epro

Product Number:PR6424/000-140+CON021

Product Type:16mm Eddy Current Sensor

Origin:Germany

Sensor Head Diameter:16 mm

Weight:0.32 kg

Views:70

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Epro PR6424/000-140 + CON021 is a high-precision eddy current sensor system designed specifically for continuous and dynamic non-contact displacement and vibration measurement in industrial rotating machinery. Manufactured by EPRO, a brand known for its excellence in vibration monitoring solutions, this sensor features a 16mm tip size and is equipped with the CON021 converter, ensuring reliable signal processing and conversion.

Its robust design and dependable performance make it particularly well-suited for harsh environments where temperature extremes, vibration, and other operational challenges are present. The PR6424 series is widely adopted in applications such as turbine monitoring, compressor systems, and critical rotating assets within petrochemical and power generation sectors.

Product Specifications

| Parameter | Details |

|---|---|

| Product Model | PR6424/000-140 + CON021 |

| Sensor Type | Eddy Current Proximity Probe |

| Sensor Head Diameter | 16 mm |

| Measurement Range | ±2 mm (typical, depending on setup) |

| Frequency Range | 0 to 10 kHz |

| Sensitivity | 7.87 mV/μm (typical with CON021) |

| Output Signal | Voltage proportional to gap |

| Probe Material | Stainless Steel |

| Mounting Thread | M14 x 1.5 |

| Cable Type | Coaxial with shield |

| Cable Length | Factory configurable (typically 5–10 m) |

| Operating Temperature Range (Probe) | –35°C to +180°C |

| Operating Temperature (Converter) | –35°C to +75°C |

| IP Protection Rating | IP65 (with appropriate installation) |

| Compliance Standards | CE, ATEX (optional depending on variant) |

| Weight | 0.32 kg |

Applications

-

Steam and Gas Turbines: Real-time shaft vibration and position monitoring for critical protection.

-

Centrifugal Compressors: Measuring radial displacement and preventing mechanical failures.

-

Pumps and Fans: Early detection of misalignment and bearing wear.

-

Electric Motors: Condition-based monitoring of rotor shaft movements.

-

Gearboxes: Detection of gear mesh anomalies via vibration analysis.

-

Industrial Rotating Equipment: General-purpose use in any critical machine where vibration and displacement data are essential.

Product Advantages

-

High Accuracy: Designed for precision vibration and position measurement in high-speed rotating machinery.

-

Wide Temperature Range: Operates reliably under extreme industrial temperatures.

-

Rugged Construction: Durable stainless steel body ensures long service life even in aggressive environments.

-

Non-Contact Measurement: Ensures zero mechanical wear and maintenance-free operation.

-

Interchangeable Components: Fully compatible with other EPRO PR6424 series sensors and CON021 converters.

-

Flexible Integration: Easy to integrate into existing CMS (Condition Monitoring Systems) and DCS.

-

Low Noise Signal Transmission: Coaxial shielding minimizes electromagnetic interference.

-

Explosion-Proof Options: Certain variants meet ATEX requirements for hazardous environments.

-

German Engineering Quality: Manufactured to strict quality standards ensuring reliability and longevity.

-

Backwards Compatibility: Compatible with earlier versions of EPRO systems for easy upgrades.

Frequently Asked Questions (FAQ)

-

What is the primary function of the PR6424/000-140 sensor?

It measures shaft displacement and vibration in non-contact mode using eddy current principles.

-

What is the significance of the CON021 converter?

It processes and converts the analog signal from the PR6424 probe into a usable output for control or monitoring systems.

-

Can I use this sensor in high-temperature environments?

Yes, the probe operates effectively up to 180°C, making it ideal for turbines and other heat-intensive machinery.

-

Is the sensor tip replaceable?

No, the sensor is factory-sealed and the tip is not user-replaceable.

-

What mounting threads are available for the PR6424/000-140?

The standard mounting thread is M14x1.5, but other thread types may be available upon request.

-

What is the recommended cable length for signal integrity?

Typically, cable lengths of up to 10 meters are supported without degradation, but this depends on the system setup.

-

Is the PR6424/000-140 compatible with older CON011 converters?

While it is optimized for use with CON021, some backward compatibility may exist depending on the application.

-

Does it require external power?

Power is supplied via the converter unit (CON021), which is typically integrated into a monitoring system.

-

Can the sensor be used in hazardous locations?

Yes, certified ATEX versions of this model are available for use in explosive environments.

-

How is the sensor calibrated?

Sensors are factory calibrated. In-field calibration is generally not required but verification against known displacement standards is possible.

Epro PR6424/000-140+CON021 16mm Eddy Current Sensor

Manufacturer:Epro

Product Number:PR6424/000-140+CON021

Product Type:16mm Eddy Current Sensor

Origin:Germany

Sensor Head Diameter:16 mm

Weight:0.32 kg

Views:70

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Epro PR6424/000-140 + CON021 is a high-precision eddy current sensor system designed specifically for continuous and dynamic non-contact displacement and vibration measurement in industrial rotating machinery. Manufactured by EPRO, a brand known for its excellence in vibration monitoring solutions, this sensor features a 16mm tip size and is equipped with the CON021 converter, ensuring reliable signal processing and conversion.

Its robust design and dependable performance make it particularly well-suited for harsh environments where temperature extremes, vibration, and other operational challenges are present. The PR6424 series is widely adopted in applications such as turbine monitoring, compressor systems, and critical rotating assets within petrochemical and power generation sectors.

Product Specifications

| Parameter | Details |

|---|---|

| Product Model | PR6424/000-140 + CON021 |

| Sensor Type | Eddy Current Proximity Probe |

| Sensor Head Diameter | 16 mm |

| Measurement Range | ±2 mm (typical, depending on setup) |

| Frequency Range | 0 to 10 kHz |

| Sensitivity | 7.87 mV/μm (typical with CON021) |

| Output Signal | Voltage proportional to gap |

| Probe Material | Stainless Steel |

| Mounting Thread | M14 x 1.5 |

| Cable Type | Coaxial with shield |

| Cable Length | Factory configurable (typically 5–10 m) |

| Operating Temperature Range (Probe) | –35°C to +180°C |

| Operating Temperature (Converter) | –35°C to +75°C |

| IP Protection Rating | IP65 (with appropriate installation) |

| Compliance Standards | CE, ATEX (optional depending on variant) |

| Weight | 0.32 kg |

Applications

-

Steam and Gas Turbines: Real-time shaft vibration and position monitoring for critical protection.

-

Centrifugal Compressors: Measuring radial displacement and preventing mechanical failures.

-

Pumps and Fans: Early detection of misalignment and bearing wear.

-

Electric Motors: Condition-based monitoring of rotor shaft movements.

-

Gearboxes: Detection of gear mesh anomalies via vibration analysis.

-

Industrial Rotating Equipment: General-purpose use in any critical machine where vibration and displacement data are essential.

Product Advantages

-

High Accuracy: Designed for precision vibration and position measurement in high-speed rotating machinery.

-

Wide Temperature Range: Operates reliably under extreme industrial temperatures.

-

Rugged Construction: Durable stainless steel body ensures long service life even in aggressive environments.

-

Non-Contact Measurement: Ensures zero mechanical wear and maintenance-free operation.

-

Interchangeable Components: Fully compatible with other EPRO PR6424 series sensors and CON021 converters.

-

Flexible Integration: Easy to integrate into existing CMS (Condition Monitoring Systems) and DCS.

-

Low Noise Signal Transmission: Coaxial shielding minimizes electromagnetic interference.

-

Explosion-Proof Options: Certain variants meet ATEX requirements for hazardous environments.

-

German Engineering Quality: Manufactured to strict quality standards ensuring reliability and longevity.

-

Backwards Compatibility: Compatible with earlier versions of EPRO systems for easy upgrades.

Frequently Asked Questions (FAQ)

-

What is the primary function of the PR6424/000-140 sensor?

It measures shaft displacement and vibration in non-contact mode using eddy current principles.

-

What is the significance of the CON021 converter?

It processes and converts the analog signal from the PR6424 probe into a usable output for control or monitoring systems.

-

Can I use this sensor in high-temperature environments?

Yes, the probe operates effectively up to 180°C, making it ideal for turbines and other heat-intensive machinery.

-

Is the sensor tip replaceable?

No, the sensor is factory-sealed and the tip is not user-replaceable.

-

What mounting threads are available for the PR6424/000-140?

The standard mounting thread is M14x1.5, but other thread types may be available upon request.

-

What is the recommended cable length for signal integrity?

Typically, cable lengths of up to 10 meters are supported without degradation, but this depends on the system setup.

-

Is the PR6424/000-140 compatible with older CON011 converters?

While it is optimized for use with CON021, some backward compatibility may exist depending on the application.

-

Does it require external power?

Power is supplied via the converter unit (CON021), which is typically integrated into a monitoring system.

-

Can the sensor be used in hazardous locations?

Yes, certified ATEX versions of this model are available for use in explosive environments.

-

How is the sensor calibrated?

Sensors are factory calibrated. In-field calibration is generally not required but verification against known displacement standards is possible.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...